Archive, Troubleshooting guide (cont.), 9040 classic hv power supply - maintenance – Ransburg 9040 Classic HV Power Supply 77070-33 User Manual

Page 30

CP-08-01

2 7

2 7

2 7

2 7

2 7

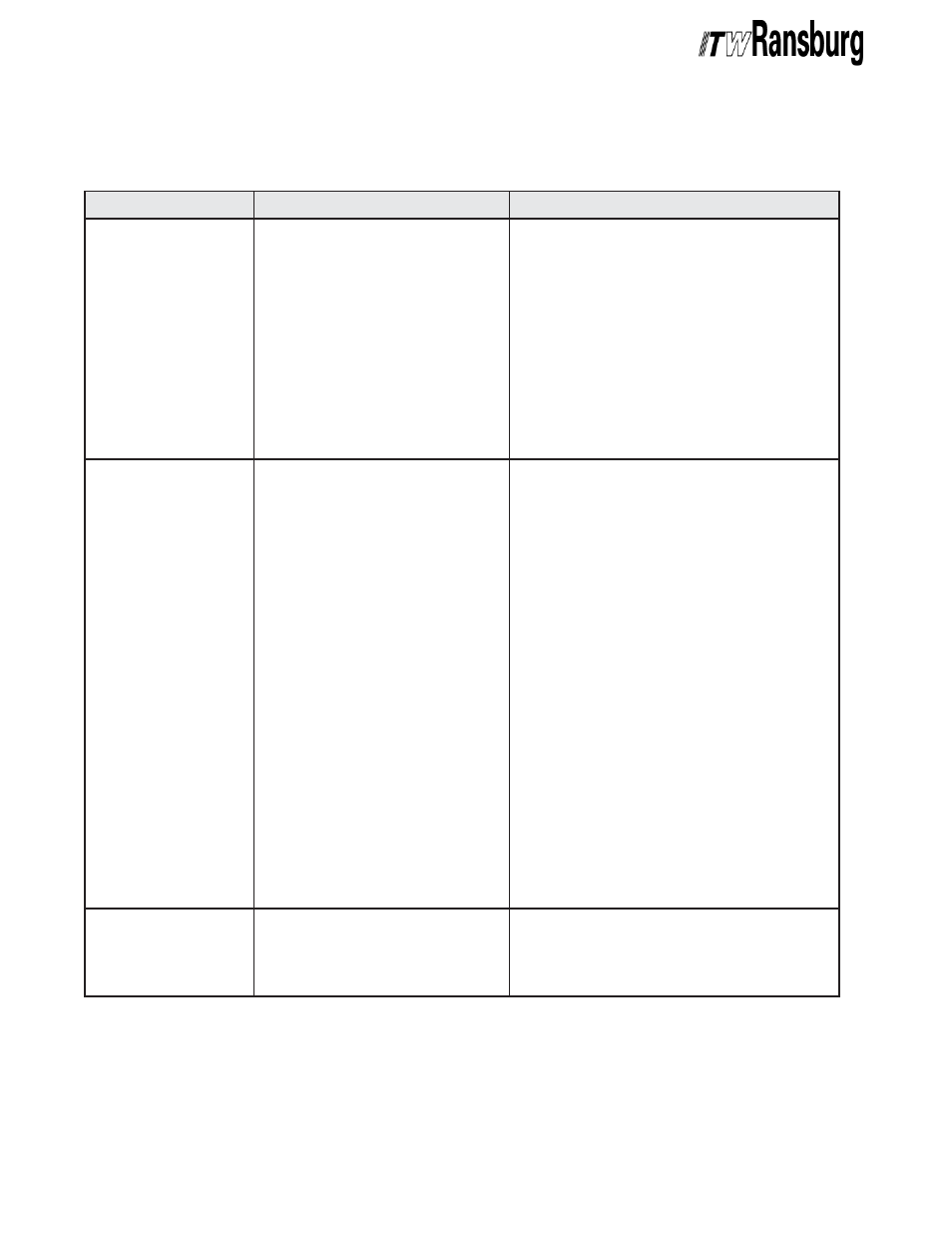

9040 Classic HV Power Supply - Maintenance

No kV Output at

No kV Output at

No kV Output at

No kV Output at

No kV Output at

Spray Applicator

Spray Applicator

Spray Applicator

Spray Applicator

Spray Applicator

and High Voltage

and High Voltage

and High Voltage

and High Voltage

and High Voltage

ON Indicator (Red

ON Indicator (Red

ON Indicator (Red

ON Indicator (Red

ON Indicator (Red

LED) is Not Lit

LED) is Not Lit

LED) is Not Lit

LED) is Not Lit

LED) is Not Lit

Power Supply

Power Supply

Power Supply

Power Supply

Power Supply

Overloads

Overloads

Overloads

Overloads

Overloads

Excessively

Excessively

Excessively

Excessively

Excessively

Component Not

Component Not

Component Not

Component Not

Component Not

Working, but kV

Working, but kV

Working, but kV

Working, but kV

Working, but kV

Output OK

Output OK

Output OK

Output OK

Output OK

1. Connector 6PL not properly

plugged into PC board

2. Improper air signal to high voltage

trigger device (air flow switch,

pressure switch, etc.)

3. Defective high voltage trigger

device (flow switch, pressure

switch, etc.) or wiring

4. Main PC board defective

1. Parts are too close to the spray

applicator

2. Overload set point set too sensitive

3. Defective spray applicator

4. Defective high voltage cable

5. Main PC board defective

6. Defective high voltage multiplier

1. Wiring to/from component loose

or broken

2. Defective component

General Problem

General Problem

General Problem

General Problem

General Problem Possible Cause

Possible Cause

Possible Cause

Possible Cause

Possible Cause

Solution

Solution

Solution

Solution

Solution

1. Properly attach connector.

2. Turn signal on and adjust to proper setting.

3. Short PC board jumper JP4. If high voltage

comes on, replace high voltage trigger device

or repair wiring from trigger device to PC board.

4. Replace main PC board.

1. Ensure sufficient distance between spray

applicator and parts.

2. Adjust PC board potentiometer 1 turn counter-

clockwise to make less sensitive. Repeat if

necessary.

3. Disconnect high voltage cable from spray

applicator and test in open air, at least 1-foot

from surrounding objects. If overload goes

away, check spray applicator for cause.

(Warning: Contact end of cable will be at

(Warning: Contact end of cable will be at

(Warning: Contact end of cable will be at

(Warning: Contact end of cable will be at

(Warning: Contact end of cable will be at

high voltage; after testing, discharge

high voltage; after testing, discharge

high voltage; after testing, discharge

high voltage; after testing, discharge

high voltage; after testing, discharge

contact by contacting to ground before

contact by contacting to ground before

contact by contacting to ground before

contact by contacting to ground before

contact by contacting to ground before

touching!)

touching!)

touching!)

touching!)

touching!)

4. Test power supply with high voltage cable

removed. If overload goes away, replace the

high voltage cable.

5. Place PC board jumper JP5 over pins 1 and 2

(overload OFF) and test. If power supply

overloads, replace main PC board.

6. If 1 thru 5 above are OK, replace the high

voltage multiplier.

1. Repair loose or broken wire.

2. Replace component.

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

ARCHIVE