Ransburg, Troubleshooting guide (cont.), Micropak controller - maintenance – Ransburg MicroPak Controller A11789 User Manual

Page 24

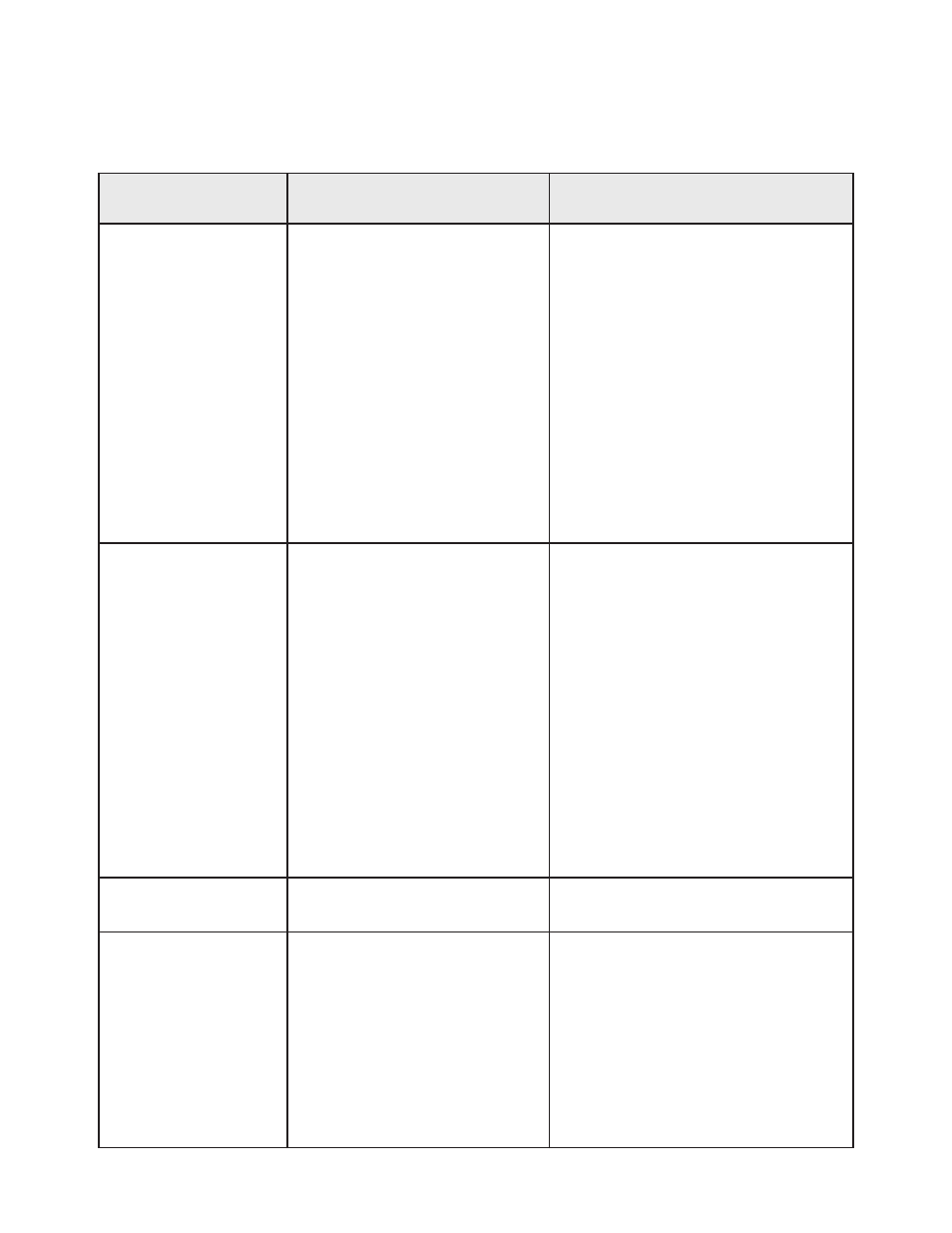

General Problem

Possible Cause

Solution

Troubleshooting Guide (Cont.)

1. Improper interlock connection.

2. High voltage ready condition not

activated.

3. High Voltage On input not acti-

vated.

4. Defective MicroPak Control Unit.

1. Parts are too close to the spray

gun.

2. Overload setpoint set too sensitive.

3. Defective spray gun or cable.

4. Defective MicroPak Control Unit.

1. Ready input is active and dip-

switch SW3-3 is off.

1. Wiring to/from component loose

or broken.

2. Defective component.

1. Ensure interlock connection is con-

nected to ground through a jumper or

voltage free contact as detailed in the

“Installation” section of this manual.

2. Activate the high voltage ready input

or set dipswitch 3-3 to the OFF position.

3. Supply 24VDC to the High Voltage

On input or if in manual mode, move

the High Voltage Enable switch to the

ON position.

4. If none of the suggestions above

resolves the issue, replace the

LECU5004-31 MicroPak Control Unit.

1. Ensure sufficient distance between

spray gun and parts.

2. Increase the μA setpoint using the

μA Adjust Knob, process board

potentiometer R21, or the 0-10VDC

over-current setpoint input.

3. Perform a Cable Continuity Test. If

proper readings are not obtained,

check cable or spray gun for cause

(see current “Spray Gun” service

manual).

4. If none of the suggestions above

resolves the issue, replace the

LECU5004-31 MicroPak Control Unit.

1. Disable ready input or turn dipswitch

SW3-3 off.

1. Repair loose or broken wire.

2. Replace component.

No kV Output at

Spray Gun and HV

ON Indicator (red

LED) is not Lit

Power Supply

Overloads

Excessively

High Voltage on all

the time

Component not

working, but kV

Output OK

MicroPak Controller - Maintenance

22

Ransburg

CP-06-01.1