Troubleshooting guide, Ransburg, Micropak controller - maintenance – Ransburg MicroPak Controller A11789 User Manual

Page 23

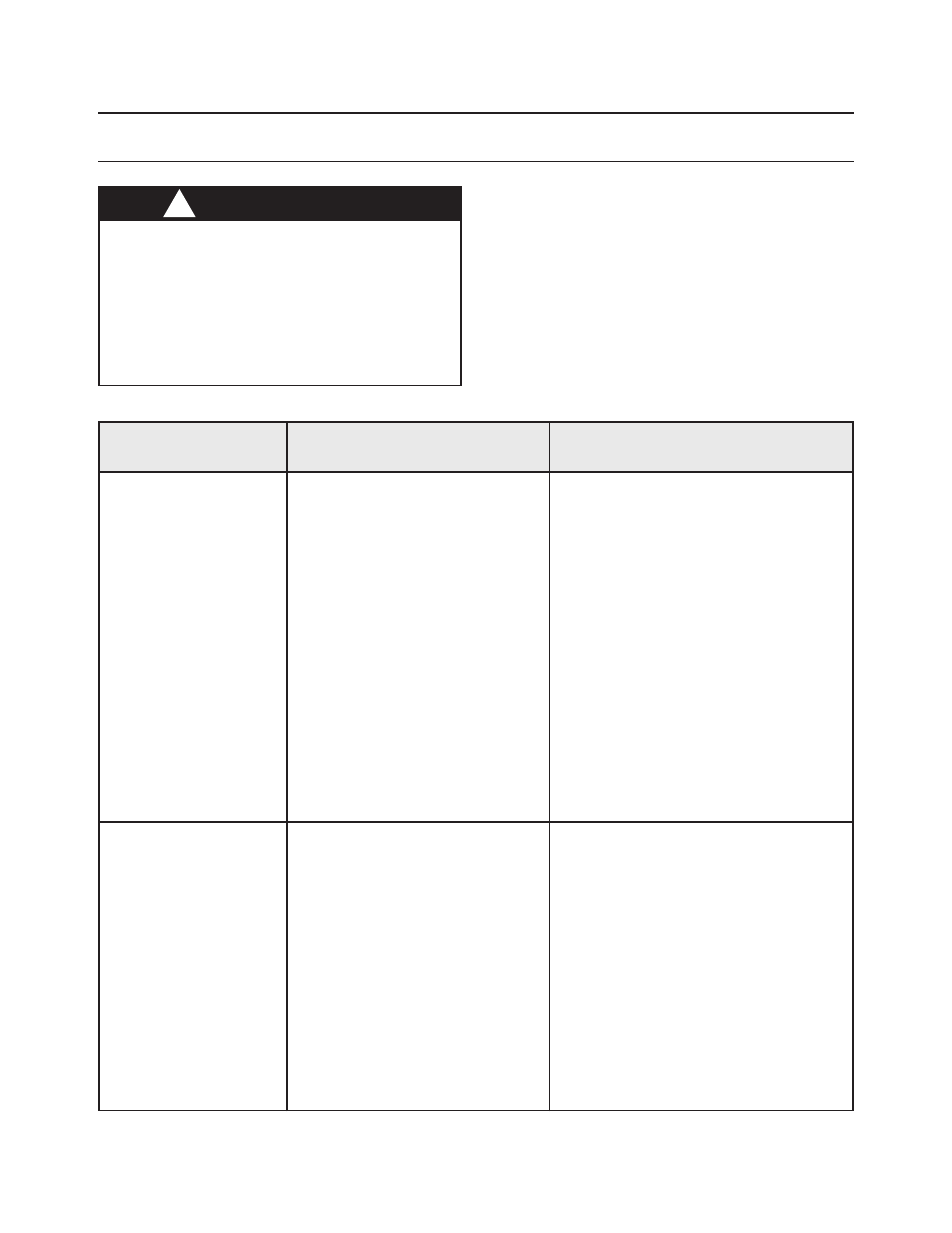

TROUBLESHOOTING GUIDE

General Problem

Possible Cause

Solution

> The “Troubleshooting Guide” below re-

quires measurement of potentials that can

cause serious bodily injury if proper measuring

procedures are not followed. For this reason,

proper troubleshooting should ONLY be con-

ducted by qualified electronics technicians

using specific test equipment.

W A R N I N G

!

(Continued On Next Page)

MicroPak Power

Indicator and Meters

do not light up when

MicroPak ON/OFF

Switch is turned ON

No or Low kV Output

at Spray Gun when HV

ON Indicator (red LED)

is Lit

1. AC Power ON/OFF switch on

rear of controller not turned ON.

2. Improper input line voltage.

3. Fuse of 24VDC power supply is

defective.

4. Defective 24VDC power supply.

5. Defective MicroPak Control

Unit.

1. High voltage adjust knob or kV

setpoint input not set to proper

value.

2. Local/remote switch in wrong

position.

3. Defective spray gun or low volt-

age cable.

4. Loose or broken wire in power

supply.

1. Turn AC Power ON/OFF Switch on.

2. Ensure voltage across terminals L1

and N of terminal block 1TB is be-

tween 90 and 264 VAC.

3. Check fuse and replace if defective

(see Figure 9).

4. Voltage across terminals 1 and 8 of con-

nector CON2 (see Figure 9) of 24VDC

power supply should be 24VDC. If not,

replace 24VDC power supply.

5. If none of the suggestions above

resolves the issue, replace the

LECU5004-31 MicroPak Control Unit.

1. Set high voltage adjust knob or kV set

point input to proper value.

2. Put local/remote switch in proper

position.

3. Perform a Cable Continuity Test. If

proper readings are not obtained,

check cable or spray gun for cause

(see current “Spray Gun” Service Manual).

4. Check all wiring connections for integri-

ty Repair wiring as needed.

MicroPak Controller - Maintenance

21

Ransburg

CP-06-01.1