Mks series – General Pump MKS Repair Manual User Manual

Page 14

GENERAL PUMP

A member of the Interpump Group

MKS SERIES

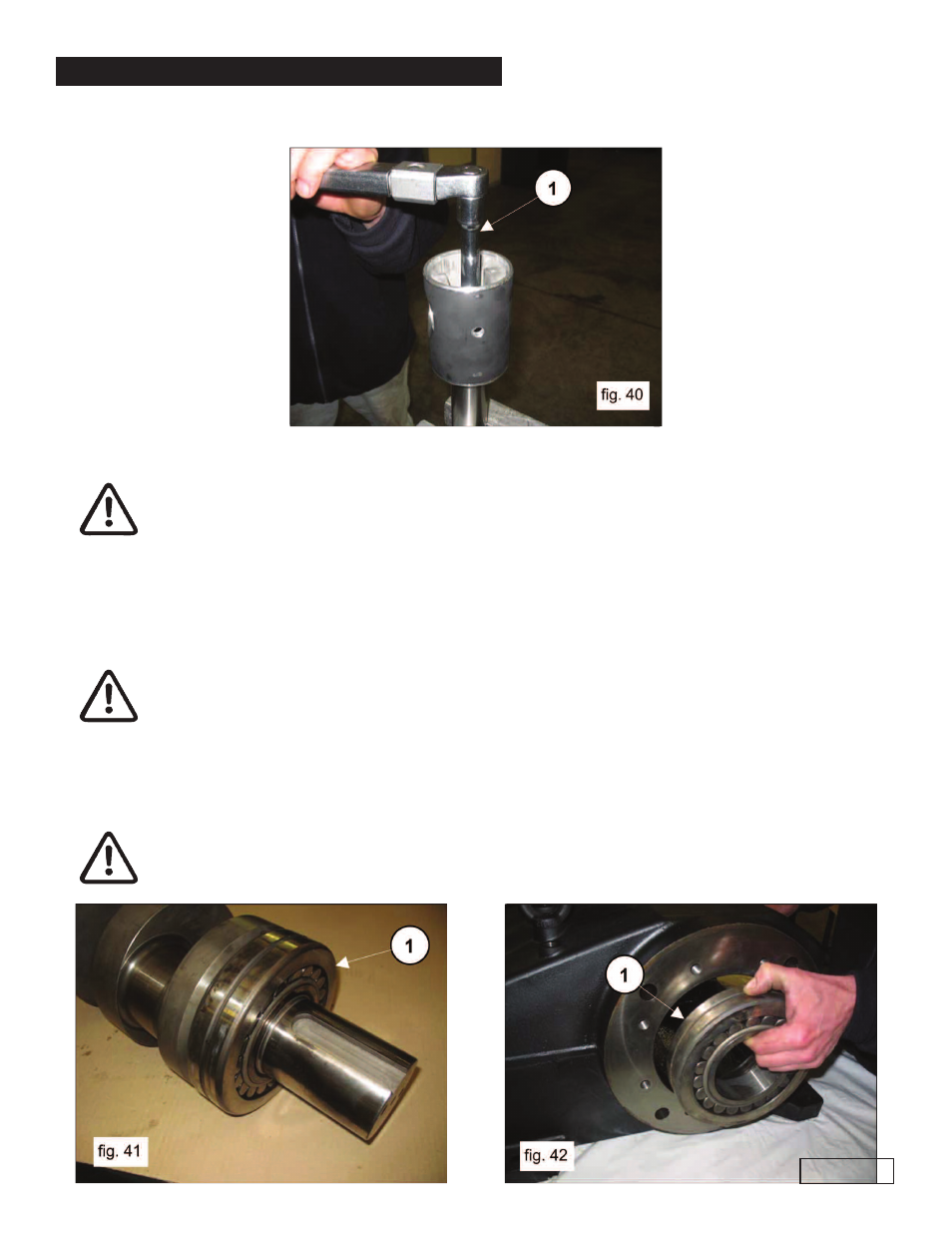

Block the rod using a clamp, and proceed with calibration using a torque wrench (1, fig. 40) as indicated

in paragraph 3. “SCREW CALIBRATION”

Insert the connecting rod in the plunger guide (1, fig. 36) and then insert the pin (1, fig. 35). Apply the

two seeger rings using the correct tool (1, fig. 34).

Make sure that conrods, plunger guides and wrist pins can move freely after being

assembled together.

Separate the caps from the connecting rod; correct coupling is guaranteed by the numbering on the side

(1, fig. 33).

After verifying the perfect cleaning of the crankcase, insert the connecting rod-plunger guide unit inside the

cylinders of the crankcase (1, fig. 32).

The insertion of the connecting rod-plunger guide unit inside crankcase must be done

by positioning the connecting rods with the numbering visible from above.

Block the three units using the correct tool, p/n F27566200(1, fig 31).

Pre-assemble the bearing, PTO side, on the shaft (1, fig. 41) and assemble the bearing on the opposite

side on the crankcase (1, fig. 42).

The bearing in fig. 42 has a tapered internal ring. Verify that the taper goes from the

outside towards the inside in order to allow the subsequent insertion of the sleeve.

Page 14

Ref 300699 Rev B

05-13