Ks series, General pump – General Pump KS Owner Manual User Manual

Page 16

GENERAL PUMP

A member of the Interpump Group

KS SERIES

Page 16

10. START UP AND RUNNING PROCEDURES

10.1 Preliminary inspections

Before start up make sure that the following conditions

have been complied with:

1. Suction line should be connected: the pump must

never run dry.

2. Suction line must be perfectly air-tight.

3. Any ON-OFF valve in between the pump and water

source should be open and make sure the water

gets into the pump freely.

4. Make sure all suction/delivery line connections are

fully tightened.

5. Coupling tolerances on the pump / transmission axis

(half-joint misalignment, Cardan inclination, belt tight-

ening, etc.) must remain within the limits indicated

by the transmission Manufacturer.

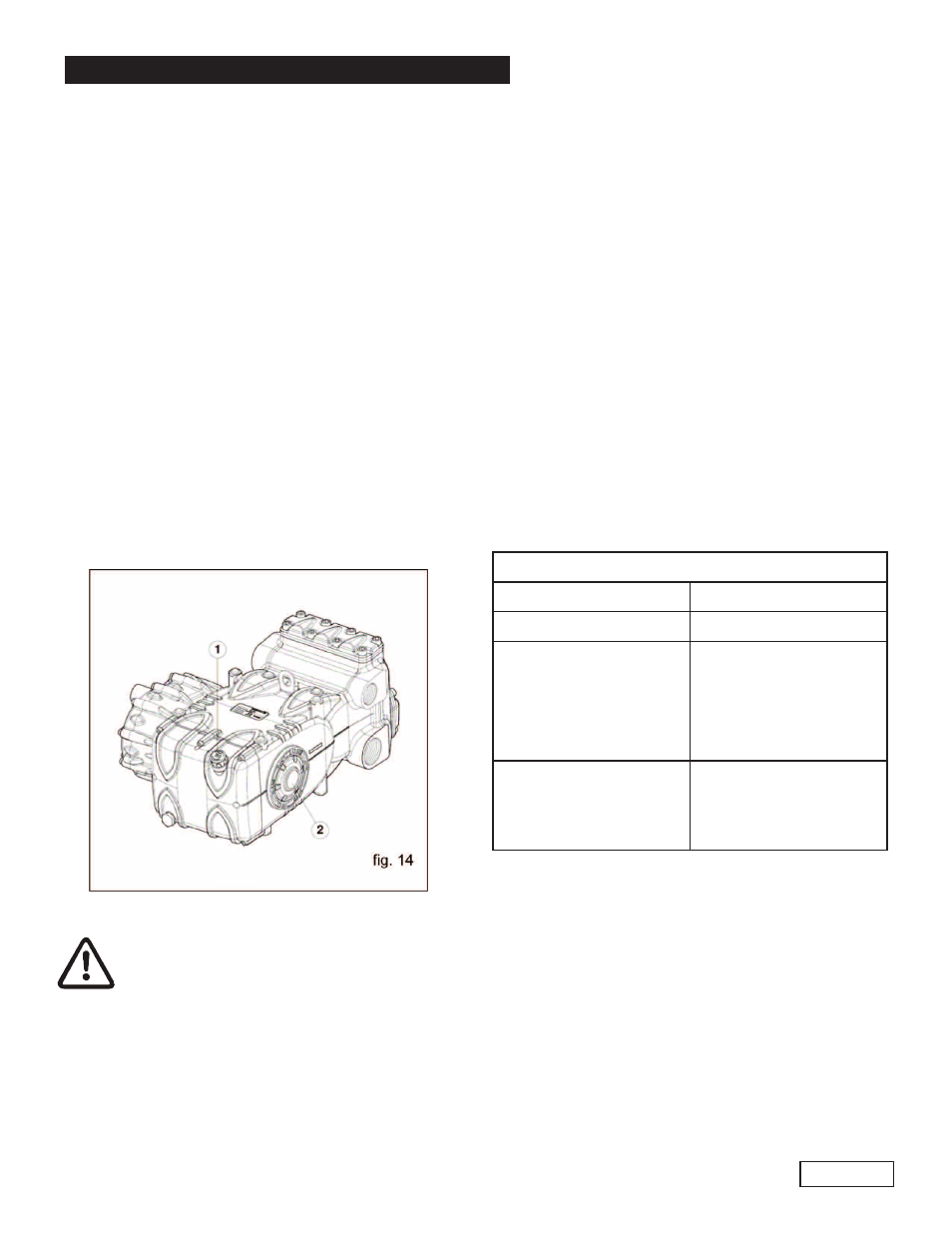

6. The oil level in the pump must be verified using the

appropriate dipsticks (position 1, fig 14), and also by

means of the oil sight glass (position 2, fig 14).

10.2 Start-up

1. When starting the pump up for the first time check

for proper direction of rotation.

2. Pump and motor/engine must start offload: set the

regulating valve to “zero” or set the pressure line

in dump mode by means of proper dumping devices.

3. Verify correct feeding pressure.

4. During operation check that the rotating speed does

not exceed the rated value.

5. Before putting the pump under pressure let it run for

at least 3 minutes.

6. Before stopping the pump release the pressure from

the system by operating the dump device or by

releasing the regulating valve and reduce RPM to a

minimum (diesel applications).

Note: in case of feeding by a centrifugal pump, make sure

that the plunger pump starts only when the correct

inlet pressure is provided.

In case the pump has not run for a long

period of time, verify the correct operation

of the suction and delivery valves.

11. PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

Every 500 hours

Every 1000 hours

Check oil level

Change oil

Check / Replace

- Valve

- Valve Seats

- Valve springs

Check / Replace

- H. P. packings

- L.P. paclomgs

Ref 300655 Rev D

09-12