Finish Thompson FM3000 Series User Manual

Page 4

1. The meter must be installed so the arrows molded in the body of the meter point away from the pump discharge.

2. Slide two o-rings (Items 3) over threads of flow meter body (item 1) until they reach the face of the body. Wrap Teflon tape on threads of

both ends of flow meter. Screw the Hose Barb Adapter (Item 2) onto discharge end of flow meter. Tighten securely by hand until it com-

presses the o-ring inside the adapter, being very careful not to over-tighten.

3. Screw coupling (item 4) onto the other end of the flow meter. The coupling is 1” NPT x 1” BSPP. The BSPP end has the larger chamfer.

Make sure the BSPP end is threaded onto the flow meter body. Tighten securely by hand until it compresses the o-ring inside the

coupling, being very careful not to over-tighten.

4. Remove discharge nut, spout and o-ring (items 9, 8, 7) from PF discharge. Discard the discharge nut and spout (or save for later use if no

longer using the pump with a flow meter). Save the o-ring for use in the next step.

5. Place the flow meter adapter (item 6) into the discharge nut (item 5) supplied with the flow meter kit. Threads of the adapter will protrude

through the front of the discharge nut. Place the o-ring (item 7) inside the discharge nut (item 5). Press down on the o-ring to ensure it is

seated in the nut.

6. Screw discharge nut/adapter/o-ring assembly onto the discharge of the PF pump tube. Use a wrench to tighten securely but do not over-

tighten. This step prevents the adapter from rotating when the flow meter is installed.

7. Grasping the flow meter body (being careful not to put pressure on the digital display), screw the flow meter assembly onto the 1” NPT

discharge adapter on the PF Series pump tube until tight. If the flow meter display is not in the upright position proceed to step 8 for

adjustment.

8. Using a wrench, loosen the discharge nut (item 5) on the discharge of the PF Series tube. Position the flow meter assembly so the display

is in the upright position and retighten the discharge nut (while holding the flow meter assembly).

NOTE: Meter can be tilted as much as 45º from upright position.

WARNING: Use chemicallly compatible hose rated for the temperature of the fluid being pumped.

9. Attach 1” ID hose to the hose barb located at the discharge end of the flow meter. Secure with a hose clamp.

Section 1 - Installation

NOTE: Avoid exposing the LCD for prolonged periods to direct sunlight or the life of the LCD may be reduced.

Section 2 - Operation

NOTES:

The FM-3000 can display either U.S. gallons or liters.

The meter is shipped from the factory with the lithium battery installed.

The FM-3000 Series is factory calibrated to ± 1% of full-scale rate reading. Accuracy is based on laboratory testing using a PF Series

pump tube.

The meter automatically turns on and begins operation when flow is detected.

Motor can only be turned ON/OFF through the meter when it is connected to the batch control relay module.

Bypass the batch control relay module by plugging the motor into a standard receptacle. The motor can now be operated from the ON/OFF

switch on the motor. The motor will now function when the meter is not in batch mode.

•

•

•

•

•

•

2

Theory of Operation

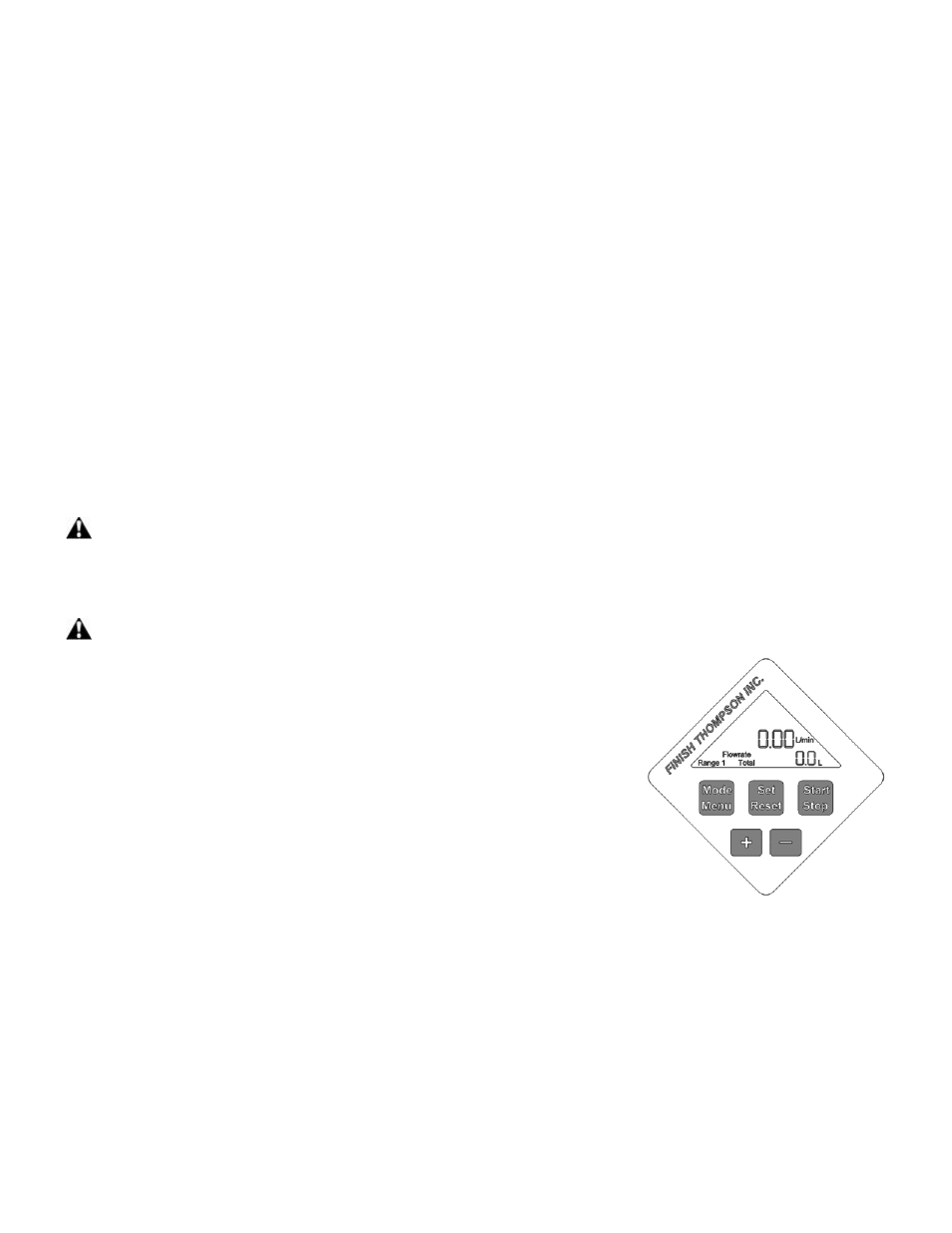

Start the pump motor. Fluid flowing through the meter causes a radial turbine wheel to spin. Pulses generated by the spinning turbine wheel

are counted and multiplied by scaling factors. The resulting flow rate amounts and total flow amounts are displayed on the LCD readout. Press-

ing the “Mode Menu” button located on the front panel toggles the display between flow rate and total flow.

WARNING: When the motor is connected to the batch control relay module make sure the motor switch is in the OFF position until ready

to use the batch control feature to prevent unintended pump operation.

Four Flow Ranges

There are four flow ranges. Range 1 is factory set for water. The other three are user adjustable. Each range totals independently from the

other ranges. These ranges can be used to calibrate the meter for different fluids or to accommodate different flow ranges (low, medium and

high flow for example).