Maintenance, Electrical, Operation – Finish Thompson KC11 SERIES User Manual

Page 2: Installation

2

SUCTION LIFT SYSTEM

1. Fully open suction and discharge valves.

2. Prime system by fi lling priming chamber and suction line with

liquid to be pumped. Allow time for trapped air to work its way

out.

3. Start the pump and check liquid fl ow. If no fl ow, see trouble-

shooting section.

4. Adjust

fl ow rate and pressure by regulating discharge valve. Do

not attempt to adjust fl ow with the suction valve.

FLUSH SYSTEMS

1. Fully close suction and discharge valves.

2. Connect water supply to water inlet valve.

3. Connect drain hose to water outlet valve.

4. Open inlet and outlet valves and fl ush system until pump is

clean (approximately 5 minutes).

MAINTENANCE

DISASSEMBLY

1. Disconnect power. Remove electrical wiring and mounting bolts

to fl oor or base plate.

2. Close suction and discharge valves, and disconnect piping.

3. Install the two-piece shipping plug into the suction of the

housing. Remove the 5 Phillips pan head screws and hex nuts

(items 7 and 9).

4. Securely clamp or hold motor in place. Remove wet end by grip-

ping the discharge with your right hand while gripping the two

fi ns marked 3 and 5 in fi gure 2. With a tight grip, pull the wet

end straight out of the motor adapter using one quick motion.

WARNING: Components can slam together from strong mag-

nets. Keep fi ngers away from area between housing and motor

adapter.

5. To disassemble wet end, remove the 4 Phillips head screws

(item 13).

6. Remove impeller housing (item 1) from barrier (item 3), and

pull out the impeller assembly (item 2). Remove o-ring (item

6). To remove drive magnet assembly (item 5), insert a 3/16"

hex wrench in the access hole on motor adapter top and loosen

the 2 set screws (item 5A). Remove the drive assembly from

the motor shaft.

To remove the drive magnet assembly, use a hook-type puller

through the 1/2" hole or a yoke-type puller through the 3/8"

threaded holes. Pull the drive by pushing off of the end of the

motor’s shaft. Always coat the motor shaft with an anti-seize

compound prior to reinstalling.

CAUTION: Strong magnets present. Keep metal objects and

metallic chips/particles away from pump components.

EXAMINATION

1. Check impeller drive bushing (item 2A), thrust ring (item 2B),

ceramic thrust rings and shaft for cracks, chips, scoring or

excess wear (See Figure 4). Replace as required.

2. Check for loose magnets on drive assembly or rubbed areas on

impeller or barrier assemblies. Contact your distributor or FTI

Technical Service if a problem is found.

ELECTRICAL

Install motor according to NEC requirements and local electrical

codes.

IMPORTANT: To verify correct motor rotation: (1) Install pump into

system. (2) Fully open suction and discharge valves. (3) Allow fl uid to

fl ow into the pump. Do not allow pump to run dry (PTFE and ceramic

bushings cannot be run dry without damage to pump components).

(4) Jog motor (allow it to run for one or two seconds) and observe

rotation of motor fan. Correct rotation is clockwise as viewed from

motor fan. Refer to directional arrow on pump.

OPERATION

FLOODED SUCTION SYSTEM

1. Fully open suction and discharge valves.

2. Start the pump and check liquid fl ow. If no fl ow, see trouble-

shooting section.

3. Adjust

fl ow rate and pressure by regulating discharge valve. Do

not attempt to adjust fl ow with the suction valve.

INSTALLATION

MOUNTING

Motor or base plate should be securely fastened.

PIPING

1. Support piping near pump to eliminate any strain on pump cas-

ings.

2. To minimize head loss from friction:

a. Increase pipe size by 1 diameter.

b. Use minimal number of pipe bends.

3. Keep bends a minimum of 10 pipe diameters from suction and

discharge.

4. Position pump as close to liquid source as possible.

5. Maintain a fl ooded suction.

6. Ensure that piping does not leak.

7. Install valves on suction and discharge lines (a minimum of 10

pipe diameters from pump).

8. For units in a suction lift system, install appropriate piping in the

discharge to allow priming of pump.

9. The suction valve should be fully open to avoid restricting suc-

tion fl ow.

IMPORTANT: To protect the pump if prime is lost, use one of

the following: (1) pressure switch on the discharge; (2) vacuum

switch on the suction; (3) a motor minder to monitor motor

current.

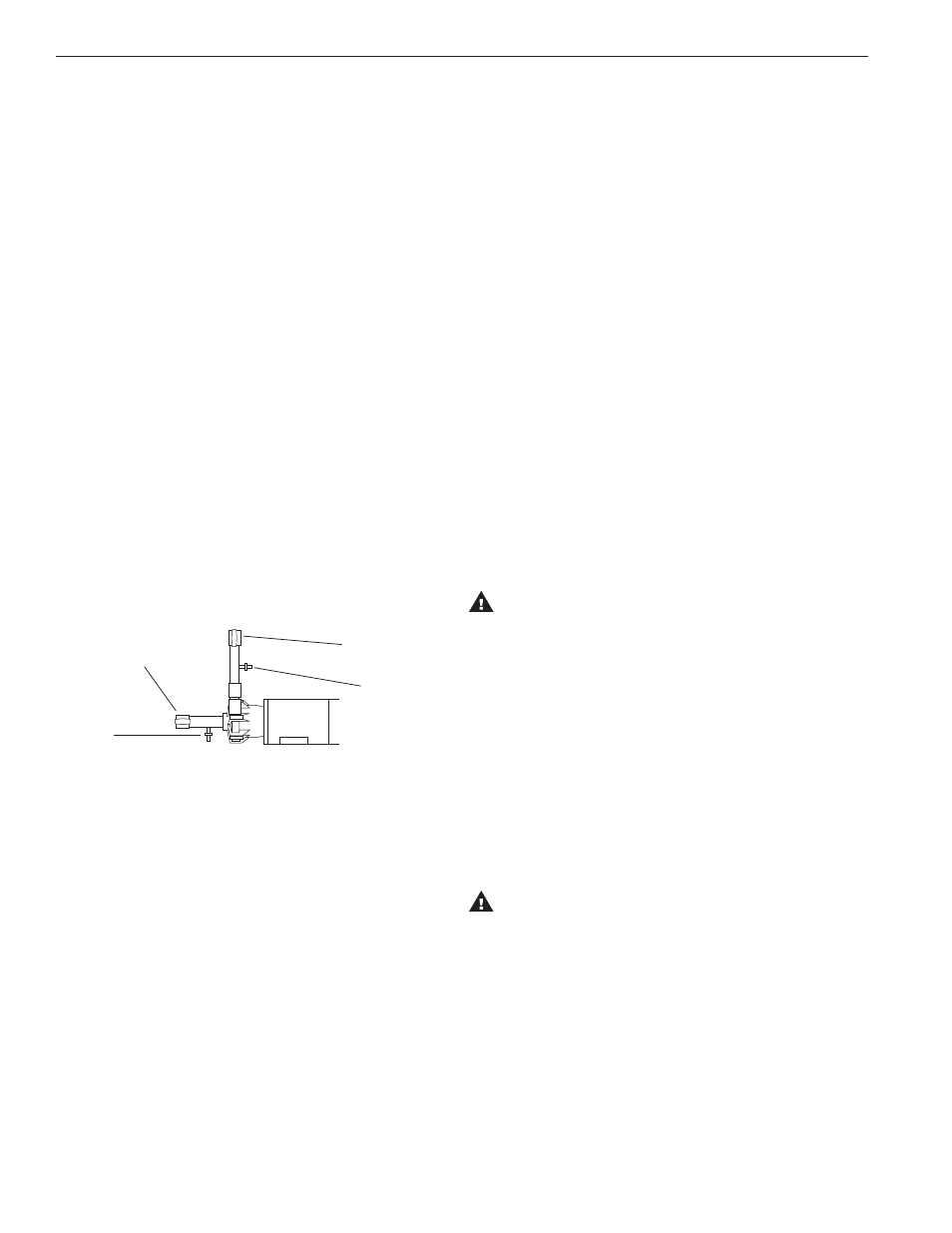

10. When pumping liquids which may solidify or crystallize, a fl ush

system should be added to the piping. See Figure 3. Install

water inlet and outlet valves as shown.

Figure 3

Suction

Valve

Discharge Valve

Water Inlet Valve

Water Outlet

Valve