Finish Thompson KC 5.5, 6, 6H, 7, 8, & 10 SERIES User Manual

Page 3

3

MAINTENANCE

DISASSEMBLY

1. Disconnect power. Remove electrical wiring and motor

mounting bolts.

2. Close suction and discharge valves. Disconnect piping.

3. Securely hold or clamp the motor in place.

4. For metric pumps, skip to step 5. For 56C frame pumps,

remove the four motor adapter bolts (items 10A, 10B, &

10C) and pull the pump end straight off of the motor

face. Place the pump end on the table with the adapter

flange on the table and the suction pointing straight up.

5. Remove the six housing bolts (item 9A, 9B, & 9C) from

the pump.

6. Using a thin bladed screwdriver, gently separate the im-

peller housing (item 1) from the barrier (item 4). Re-

move the housing o-ring (item 7). Gently separate the

barrier from the motor adapter (item 5). On metric

pumps, carefully separate and rotate the barrier tabs so

that they are located in between the motor adapter bolt

holes. Gripping the tabs, pull the barrier and impeller

assembly from the pump. Remove the impeller assembly

(items 2 and 3) from the barrier.

7. Remove the drive magnet assembly (item 6) using a 5/

32” hex wrench on the two set screws. Metric pumps

have access holes in the motor adapter to loosen set

screws.

CAUTION: Keep the drive magnet and impeller assem-

blies away from metal chips or particles.

OPERATION

FLOODED SUCTION SYSTEM

1. Completely open suction and discharge valves

2. Start the pump and check liquid flow. If there is no flow,

see the Troubleshooting section.

3. Adjust the flow rate and pressure by regulating the dis-

charge valve. Do not attempt to adjust the flow with the

suction valve.

ELECTRICAL

1. Install the motor according to NEC requirements and local

electrical codes. The motor should have an overload protection

circuit.

2. Wire the motor for clockwise rotation when facing the fan

end of the motor.

3. To verify correct rotation of the motor:

a. Install the pump into the system.

b. Fully open the suction and discharge valves

c. Allow fluid to flow into the pump. Do not allow the pump

to run dry (PTFE and ceramic bushings can’t be run dry

without damage to pump components).

d. Jog the motor (allow it to run for only one to two

seconds) and observe the rotation of the motor fan.

Refer to the directional arrow on the pump if needed.

Note: A pump running backward will pump but at a

greatly reduced flow and pressure.

Suction

Valve

Water

Outlet

Valve

Discharge Valve

Water Inlet Valve

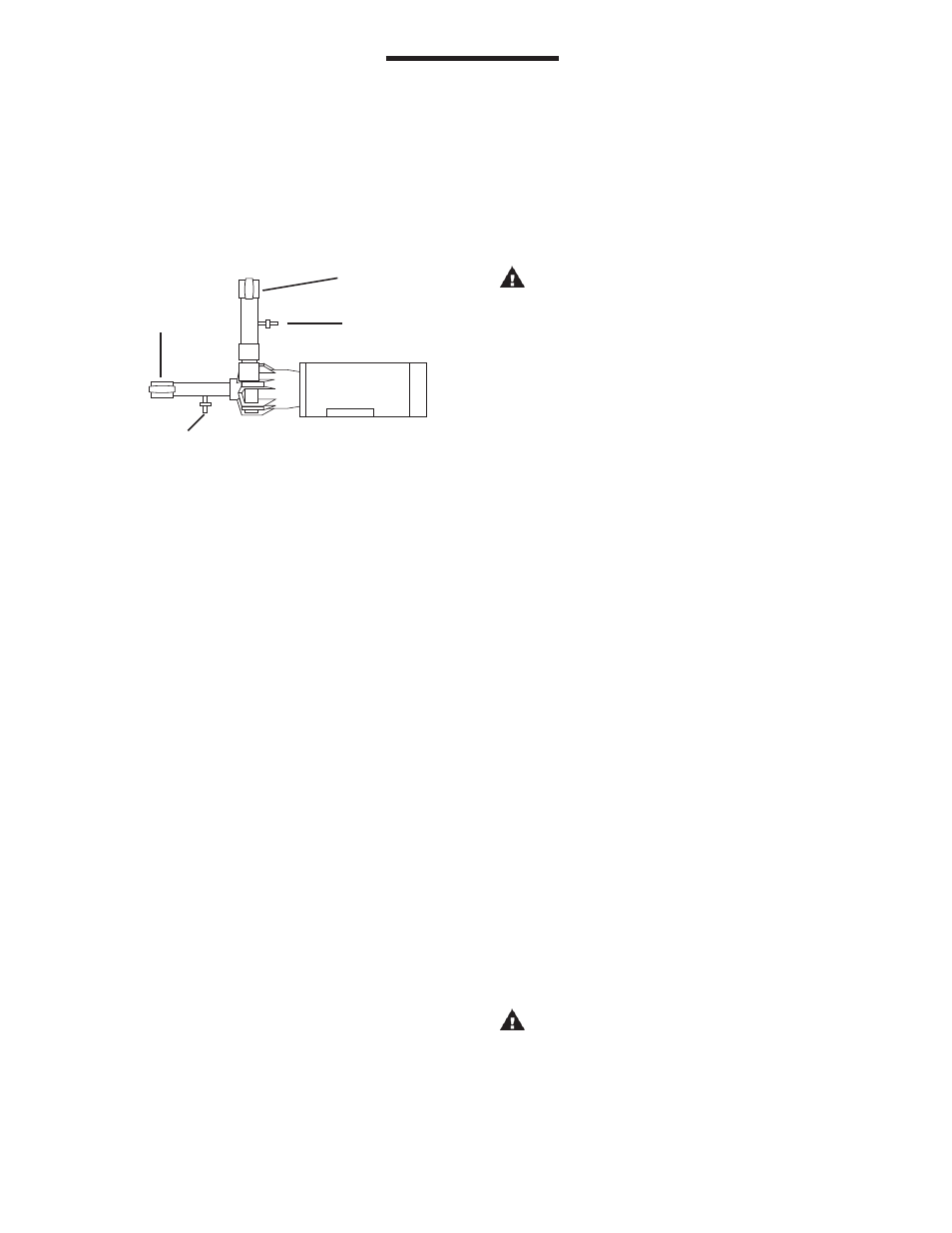

Figure 4

SUCTION LIFT SYSTEM

1. Prime the system by filling the priming chamber and/or

suction line with a liquid. Allow time for trapped air to

work its way out.

2. If priming via filling the suction line, close the discharge

valve prior to returning the suction line to the tank.

FLUSH SYSTEMS

CAUTION: Some liquids react with water.

1. Completely close suction and discharge valves.

2. Connect water supply to water inlet valve.

3. Connect drain hose to water valve.

4. Open inlet and outlet valves. Flush system until pump is

clean (approximately 5 minutes).

EXAMINATION:

1. Check impeller drive bushing (item 3A), thrust ring, ce-

ramic thrust ring and shaft for cracks, chips, scoring or

excess wear. See Figure 5. Replace as required.

12. When pumping liquids that may solidify or crystallize, a

flush system should be added to the piping. See Figure 4.

Install water inlet and outlet valves as shown.

Note: This pump is provided with a provision for a customer

installed 1/4” NPT drain in the impeller housing. See Drain

Installation Section for details.