Finish Thompson DB6, 6H, 7, 8, 9, 10 Series User Manual

Page 8

Flush Systems

CAUTION: Some fluids react with water; use compatible flushing

fluid.

1. Turn off the pump.

2. Completely close the suction and discharge valves

3. Connect flushing fluid supply to flush inlet valve.

4. Connect flushing fluid drain to flush drain valve.

5. Open flushing inlet and outlet valves. Flush system until the pump

is clean.

Optional Drain Installation

1. Remove the impeller housing (item 1) from the pump assembly.

2. Clamp the impeller housing to a drill press table.

3. Using a 7/16” drill and the molded boss as a guide, drill com-

pletely through the molded boss into the interior of the impeller

housing.

CAUTION: Do not tap too deep or the impeller housing may be

damaged.

4. Using a ¼” NPT tap, tap the hole in the molded boss to the ap-

propriate depth.

5. Install the drain plug or valve, being careful not to over-tighten.

Section IV - Maintenance

Recommended maintenance schedule

The recommended maintenance schedule depends upon the nature

of the fluid being pumped and the specific application. If the pump is

used on a clean fluid, it is recommended that the pump be removed

from service and examined after six months of operation or after 2,000

hours of operation. If the pump is used on fluids with solids, high tem-

peratures or other items that could cause accelerated wear, then this

initial examination should be sooner.

After the initial examination of the internal components and wear items

are measured, a specific maintenance schedule can be determined.

For best results, it is recommended that the pump be removed from

service annually for examination.

Section V - Disassembly

WARNING: Rotating Parts. This pump has components that rotate

while in operation. Follow local safety standards for locking out the

motor from the power supply during maintenance or service.

WARNING: Chemical Hazard. This pump is used for transferring

many types of potentially dangerous chemicals. Always wear protective

clothing, eye protection and follow standard safety procedures when

handling corrosive or personally harmful materials. Proper procedures

should be followed for draining and decontaminating the pump before

disassembly and inspection of the pump. There may be small quanti-

ties of chemicals present during inspection.

WARNING: Magnetic force hazard. This pump should only be dis-

assembled and assembled using the recommended procedures. The

magnetic attraction is powerful enough to rapidly pull the motor end

and the wet end together. Do not place fingers between the mating

surfaces of the motor and wet ends to avoid injuries. Keep the drive

magnet and impeller assembly away from metal chips or particles.

1. Stop the pump, lock out the motor starter, close all the valves that

are connected to the pump, and drain/decontaminate the pump.

WARNING: The pump must be thoroughly flushed of any haz-

ardous materials and all internal pressure relieved prior to opening

the pump. Allow the pump to reach ambient temperatures prior to

performing maintenance.

2. Securely clamp the motor to the bench. Remove the (4) bolts, lock

washers and flat washers (items 24, 25, 26) securing the pump to

the motor.

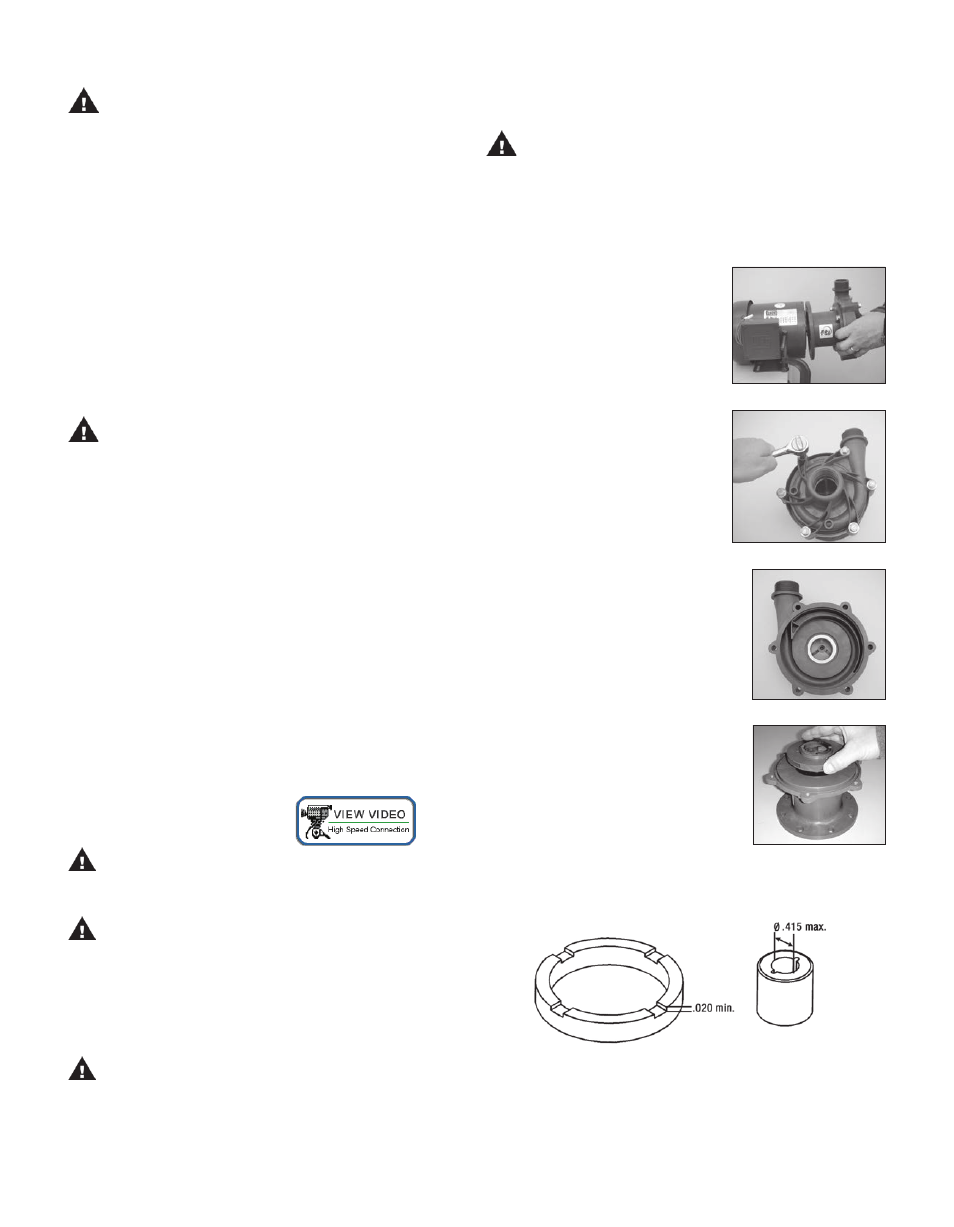

3. Firmly grab the pump and pull straight

back to disengage the motor and the

pump. See figure 10.

4. Place pump on bench with housing

facing up. Remove (6) 8 mm hous -

ing bolts, lock washers and flat

washers (items 15, 16, 17). See

figure 11.

5. Pull housing (item 1) straight up to

remove. Inspect housing for signs of

wear or damage. Look for signs of

rubbing, cracked thrust ring or dam-

age to front shaft support. See

figure 12.

6. Remove impeller/inner drive assembly

(items 4A, 4, 5, 5A). Inspect impeller

and drive for signs of wear or damage.

Look for signs of rubbing, damage and

wear to the impeller and inner drive.

See figure 13.

Check the impeller thrust ring and

bushing for wear. See figure 14.

5

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14