General Technologies TA500 SmarTach+COP : Multisystem Engine Analyser User Manual

Page 5

Page 8

Page 7

4- Select the measurement to show in the main display: RPM, spark burn time or

spark KVolt.

5- Select the mode for the secondary display: Minimum and Maximum of the main display

or the complementary measurements.

6- Place the capacitive pick-up (yellow tip of the probe), as shown in Fig. 4 below, over

one of the ignition modules, searching for the position that produces a stable RPM or

spark burn time reading.

7- If this is the first measurement taken in the engine, then proceed to calibrate the spark

KVolt measurement first (following the procedure in ‘3.3.4 Main Function / Calibrate

button‘), as this calibration value will be used as a reference value to compare the

spark KVolt reading between all the coil on plug or coil near plug modules.

8- Place the capacitive pick-up over the ignition modules and read the measurements

in the display.

Fig. 4 - Capacitive pickup on coil on plug module

Coil on Plug module

Capacitive pickup

Important:

• In some engines, the ignition modules are located very close together, and this may

cause the TA500’s capacitive pick-up to receive signals from nearby modules, which

may cause false readings.

• To reduce interference from others ignition modules, cover completely the nearby

ignitions modules with pieces of aluminum foil, making sure the aluminum foil is

connected to a good electrical ground in the engine (e.g. valves cover, mounting

bolts).

CAUTION

To avoid personal injuries and damage to the instrument carefully inspect the

spark plug wires, distributor cap, ignition coil , ignition module, and all other

ignition system parts for damage or leaks, and avoid using this instrument in

case any damage or leaks are found. Never touch the capacitive pick-up or

flexible probe during a test. Wear insulating gloves when working around high

voltage, and hot parts, and keep away from moving parts (fan, drive belts, etc)

and hot objects (exhaust manifold and pipes, muffler, catalytic converter, etc.)

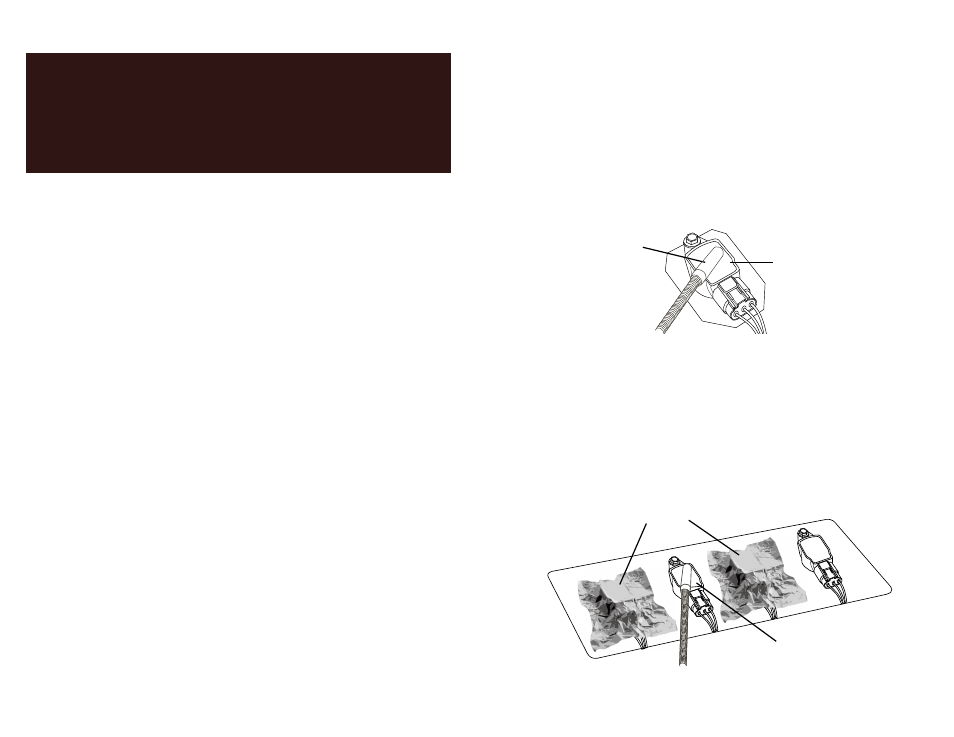

Nearby ignition coils shielded

with aluminum foil

Ignition coil under test

Probe

Fig. 5 - Avoiding interference by shielding nearby ignition coils

3.4 Measurement Procedures

3.4.1 TA500 measuring functions

The TA500 has specially dedicated modes for use in the diagnostics and

troubleshooting of Coil on Plug and Coil near Plug ignition technology, and for systems

using spark plug wires. These special modes compensates for differences in signal strength

and waveform patterns between ignition systems.

The TA500 can measure the following:

• Engine RPM,

• Spark burn time, and

• Spark KVolt (relative measurement).

3.4.1.1 Engine RPM

Measures engine RPM in 2, 4 cycles and DIS engines, and it can be used in

combination with spark burn time and spark KVolt measurements, to evaluate the ignition system

performance at different engine speeds.

3.4.1.2 Spark burn (firing) time

The spark burn time, also called “firing time”, is the measurement of the time period from

the moment that a spark is initiated up to the point when it is extinguished, and is the most

indicative measurement of performance of the ignition system. Abnormally long or short

burn times may indicate some problem in the ignition module, spark plug, fuel mixture,

cylinder compression, etc.

3.4.1.2 Spark KVolt

Spark KVolt values are relative measurements, useful to compare the performance of the

ignition system in each cylinder. Comparing spark KVolt between cylinders may be used

to diagnose common problems like misfires, broken spark plug wires, etc. However spark

KVolt values may vary widely, are less consistent and not always indicative of a properly

working ignition system.

3.4.2 Measuring Coil on Plug and Coil near Plug ignition systems

1- Turn the instrument on.

2- If not already in

COP mode, select it by pressing the ‘Ignition System’ button.

3- Select the number of cycles for the engine under measurement by pressing the ‘Engine

Cycles’ button repeatedly until the display shows the correct setting.