FEC AFC1200 User Manual

Page 4

)(& ,QF

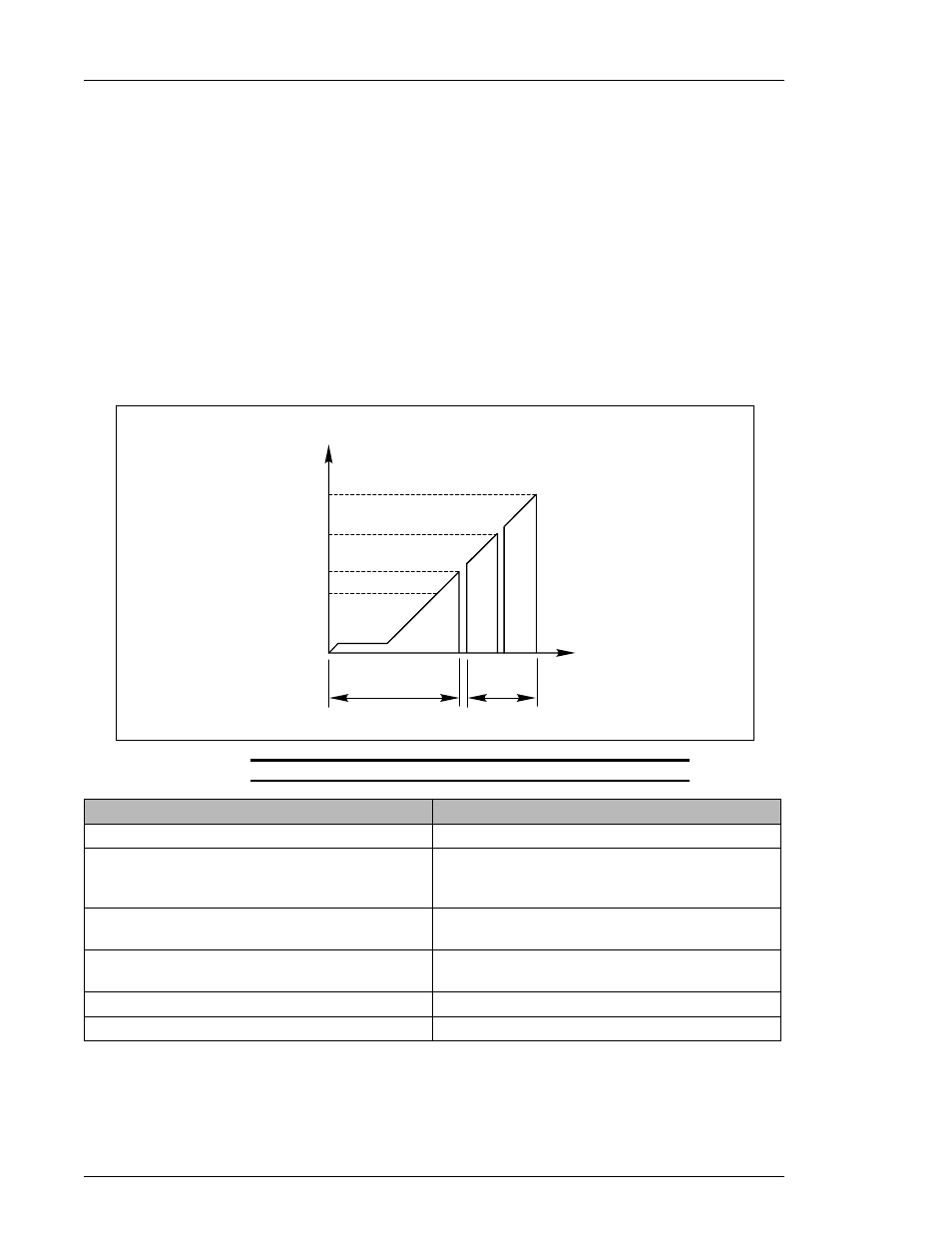

P After presetting the fastening sequence (SET SEQUENCE Section 7.5) to perform

a three-step fastening, the System fastening parameters (PARAMETER SET

Section 7.1) must be configured according to the Engineered fastening

specification.

P Three-step fastening will be used primarily for joints that have a requirement to

synchronize with another spindle during the incremental stages of the rundown to

crush/compress a gasket or grommet.

Examples: Valve cover, oil pan, body assembly.

P The System will fasten to 1st TORQUE during the specified 1ST STEP time. Once

either SPEED CHANGE TORQUE or 1st TORQUE is reached the System will

switch to the specified TORQUE SPEED (Section 6.3). When all fasteners have

reached 1st TORQUE, the spindles will synchronize and fasten simultaneously to

2ND during FINAL STEP time. When all fasteners have reached 2ND, the spindles

will synchronize again and fasten simultaneously to STD during FINAL STEP time.

STD.

TORQUE

1ST STEP

FINAL

STEP

ANGLE

SPEED CHANGE

1st TORQUE

2ND

FIG. 6-1-1c Torque Control Functions for Three-Step Fastening

Maximum allowable 2nd and Final step times

FINAL STEP (TIME)

Maximum allowable 1st step cycle time

1ST STEP (TIME)

30 ~ 50% of STD for Hard joints

50 ~ 90% of STD for Soft joints

SPEED CHANGE (TORQUE)

30 ~ 50% of STD for Hard joints

50 ~ 90% of STD for Soft joints

1st TORQUE

30 ~ 50% of STD for Hard joints

50 ~ 90% of STD for Soft joints

Set above 1st TORQUE/ANGLE

2ND (TORQUE)

Engineered fastening specification

STD (TORQUE)

RECOMMENDATION

FUNCTION

{ Four-Step Fastening

Chapter 6: Fastening Instructions

User Console Version A3.53

Page 6-4