FEC AFC1200 User Manual

Page 13

)(& ,QF

P For a standard two-step operation, the System will fasten to 1st TORQUE/ANGLE

during the specified 1ST STEP time. Once either SPEED CHANGE TORQUE or

1st TORQUE/ANGLE is reached, the System will switch to the specified TORQUE

SPEED (Section 6.3). When all fasteners have reached 1st TORQUE/ANGLE, the

spindles will synchronize and then fasten simultaneously until the desired bolt

stretch has been reached, within the specified FINAL STEP time. Once

CROSSOVER AREA is attained or exceeded, the actual elongation area is

compared to the calculated elongation area. When the actual elongation area is

equal to or greater than the calculated elongation area, the proper bolt stretch has

been obtained.

NOTES: Setup for Torque Control and Angle Control items are detailed in separate Sections.

Yield Control Method cannot be configured properly without first performing extensive

testing on the joint.

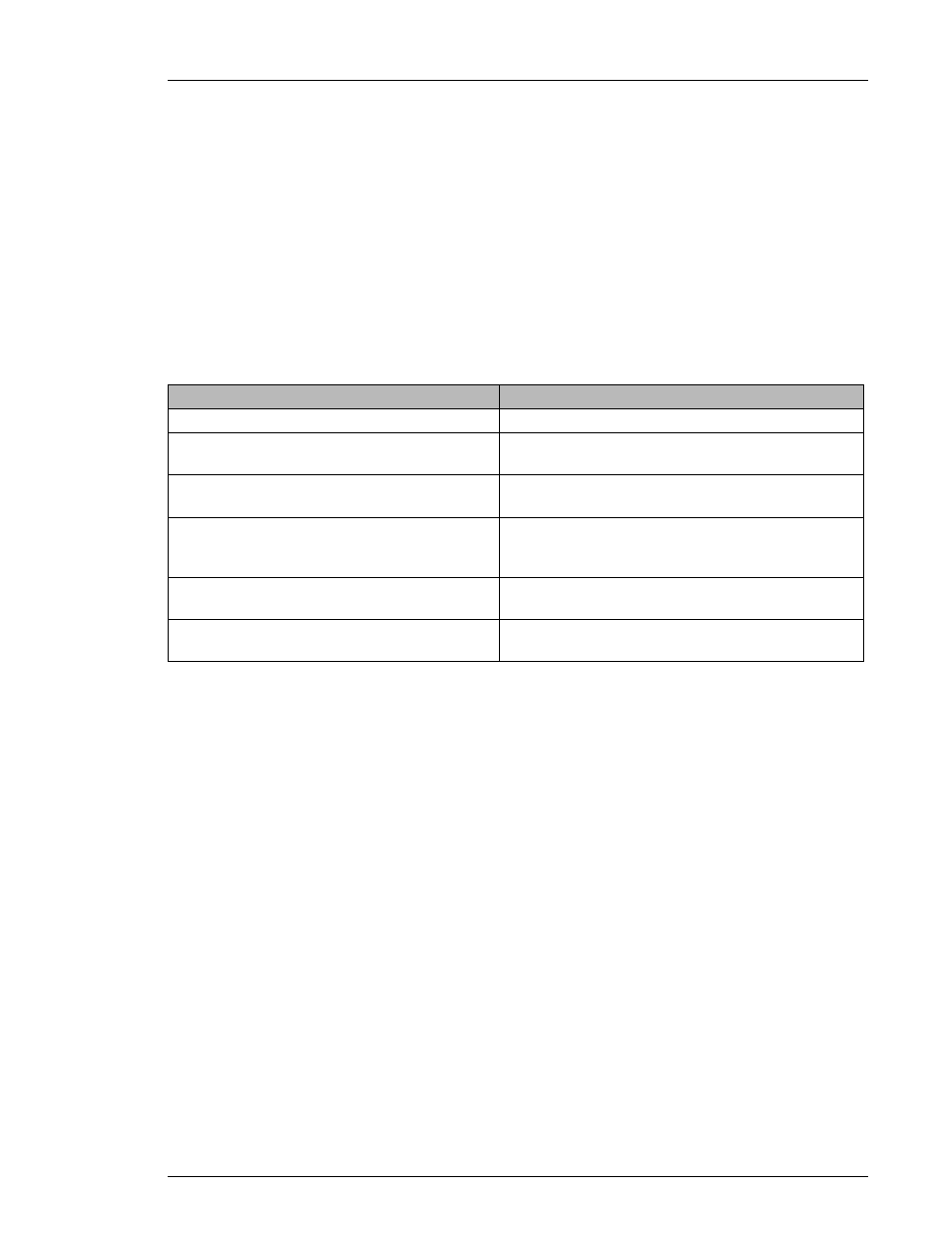

Start point of area yield method. Set based upon

extensive testing

CROSSOVER AREA (TORQUE/ANGLE)

Compensation factor for calculated bolt stretch. Set

based upon extensive testing

CONSTANT

Expectant torque rate of fastener when proper bolt

stretch has been obtained. Set based upon

extensive testing

YIELD RATE

Engineered fastener rotation into yield specification.

Automatically set when "length" is set

ANGLE

Engineered fastener permanent elongation

specification. Automatically set when "angle" is set

LENGTH

Fastener specification

SCREW PITCH

RECOMMENDATION

FUNCTION

Chapter 6: Fastening Instructions

User Console Version A3.53

Page 6-13