6 troubleshooting – Teledyne MD300 - Oxygen analyzer and monitor (Diving) User Manual

Page 31

Portable Oxygen Monitor

Service Manual

Teledyne Analytical Instruments

31

unit, the discrepancy in oxygen readings persists, the problem is most

likely elsewhere. Further investigation should be made until the

discrepancy in readings is resolved. The troubleshooting section of this

manual may provide additional assistance in locating the problem.

Note: The MSDS on this material is available upon request

through the Teledyne Environmental, Health and Safety

Coordinator at (626) 934-1592 or can be viewed and

downloaded from our web site at www.teledyne-ai.com.

3.6 Troubleshooting

The AD300 and MD300 oxygen monitors provide a variety of built-in

safety features that prevent its use when a fault is detected. When a unit

displays the message √ SENSOR and sounds the audible and visual alarm

continuously, it is an indication of a faulty connection between the sensor and

the unit or an expired or faulty sensor. To determine where the difficulty lies,

refer to the following guidelines in Table 3-1.

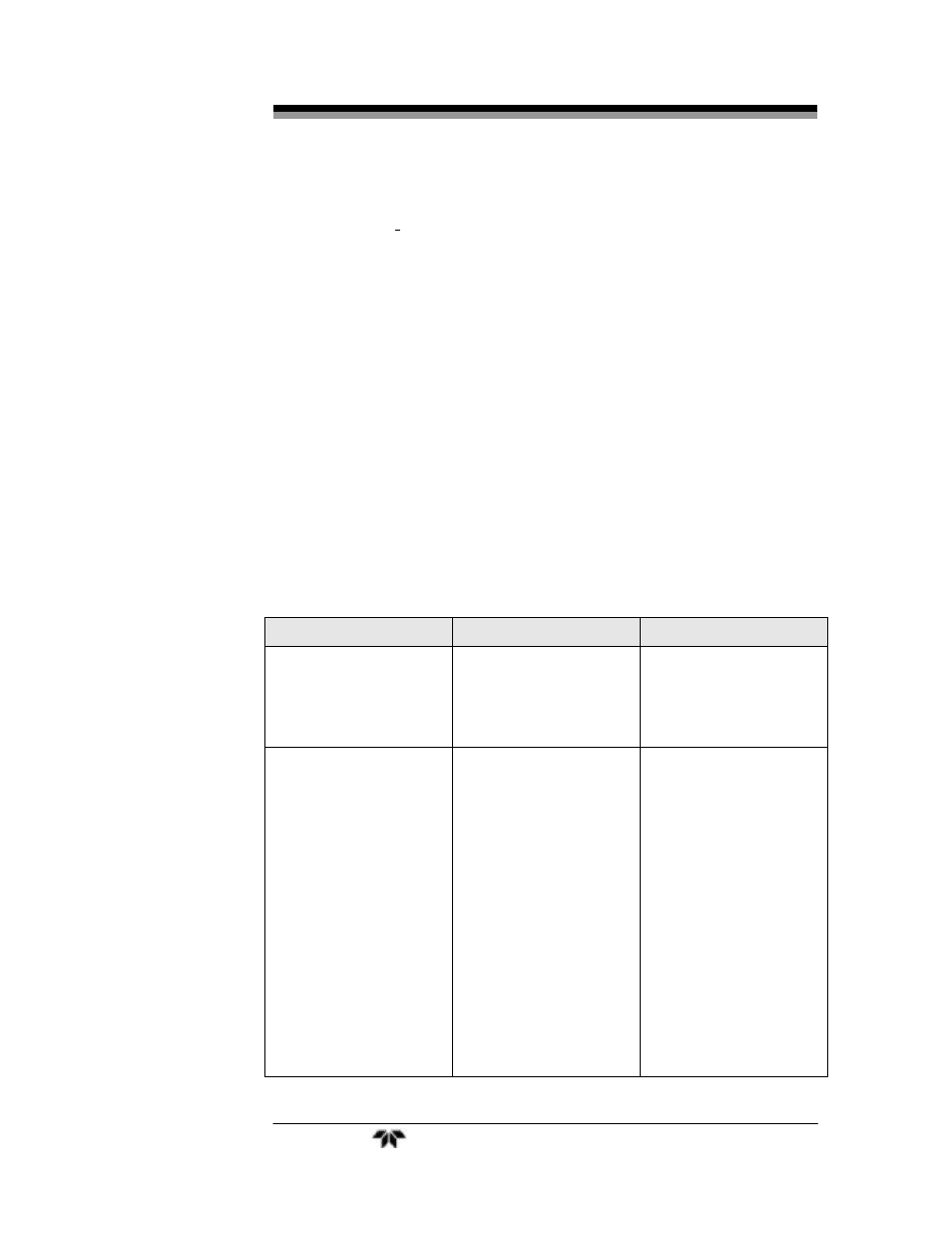

Table 3-1 Troubleshooting

Symptom

Why

What To Do

New sensor responds

slow or drifts.

If the sensor is new and

was just removed from

its sealed bag it may

need to run for several

hours.

A) Wait 30 minutes and

recalibrate.

Sensor will not read below

22 % after calibration in

100% O2.

Calibration in 100% was

invalid or the room air is

contaminated with

excess oxygen.

A) Recalibrate using

dry gas making sure

the reading

stabilizes before

making any

adjustments.

B) Make sure that at

least 6" (30 cm.) of

tubing is attached to

the exhaust side of

the tee adapter to

prevent back filling.

O2 flow rate should

not exceed 5 l/min.

C) Oxygen

concentration at the

sensor is significantly