4 sample system – Teledyne 3000MA - Paramagnetic oxygen analyzer User Manual

Page 17

2-5

Percent Oxygen Analyzer

Operational Theory 2

Teledyne Analytical Instruments

(0% 0

2

) - (Cross Interference Value) = Zero Point Value

0% -(-0.137) = +0.137%0

2

2.4

Sample System

The sample system delivers gases to the sensor from the analyzer gas

panel inlets. Depending on the mode of operation either sample or calibration

gas is delivered.

The Model 3000MA sample system is designed and fabricated to ensure

that the oxygen concentration of the gas is not altered as it travels through the

sample system. The sample encounters almost no dead space. This minimizes

residual gas pockets that can interfere with low percent range analysis.

The sample system for the standard instrument incorporates ¼ inch tube

fittings for sample inlet and outlet connections at the rear panel. For metric

system installations, 6 mm adapters are available with each instrument to be

used if needed. The sample or calibration gas flowing through the system is

monitored by a flowmeter downstream from the sensor.

The gases delivered to the instrument should be at constant pressures and

flow rates and must exit freely into the ambient atmosphere. The Span, Zero

and Sample gases should be delivered at constant pressures of about 10 psig

(Range 5-20). The flow rate must be maintained at about 700 cc/minute (Range

500-900) and must exit freely into atmospheric pressure.

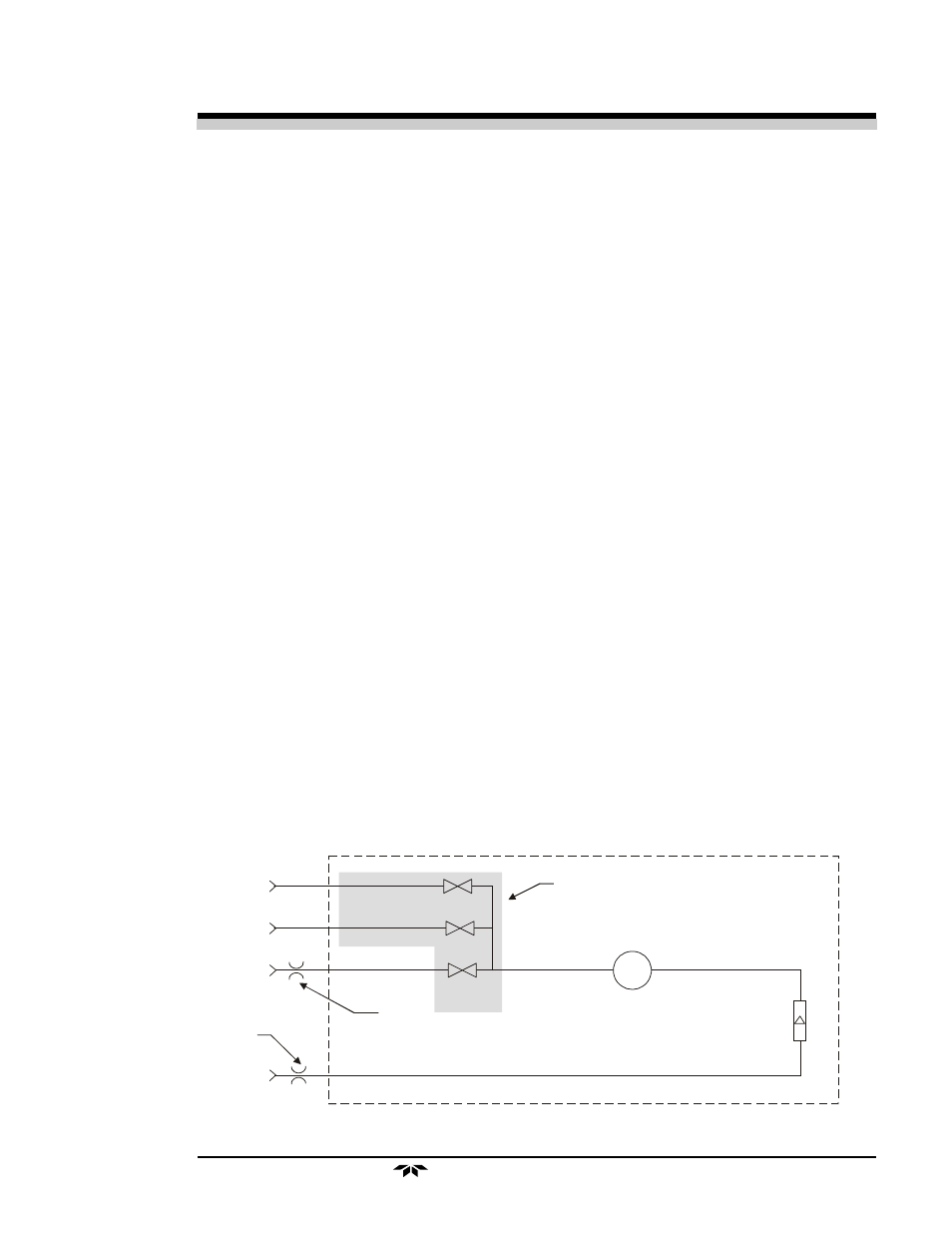

Figure 2-4 is the flow diagram for the sampling system. In the standard

instrument, calibration gases (zero and span) can be connected directly to the

Sample In port by teeing to the port with appropriate valves. The shaded por-

tions of the diagram show the components added when the –C options are

ordered. The solenoid valves, when supplied, are installed inside the 3000MA

enclosure and are regulated by the instruments internal electronics.

Figure 2-4: Flow Diagram

In vacuum service the

restrictor should be

placed here.

Sample In

Span In

Zero In

Flowmeter

Exhaust Out

Solenoid

Valves

Restrictor

Cell

In normal service the

restrictor should be

placed here.

Components in the shaded area are in

the -C option (internal control valves)

only and are not shown in the piping

diagram above.