Teledyne 1220 - Multipoint flammable gas and vapor detection system User Manual

Page 14

2-4

2 Operational Theory

Model 1220

Teledyne Analytical Instruments

When exposed to a mixture containing gases and oxygen, the measur-

ing bead coating allows the oxygen and combustibles to combine at its

surface. The energy produced by this reaction heats the measuring bead.

The rise in temperature changes the bead’s resistance and is related to the

concentration of the combustible gas. The reaction rate is dependent upon

the nature of the particular combustible gas. Raising the temperature of the

bead increases the reaction rate, which increases the sensitivity of the

sensor and reduces the observed differences of various gases. This rise in

temperature is generated by a constant-current supplied to the sensor.

The temperature of the measuring bead will be influenced by other

factors such as initial gas temperature, gas thermal conductivity, flow rates

and the temperature of its housing. The reference bead, having similar

electrical and thermal properties and being heated by the same current, but

lacking the catalytic material will be similarly affected by these extraneous

factors but not significantly affected by oxidation of the combustible gas.

These two beads are placed in close proximity to one another so that

they are affected by the same environmental factors. Thus the differences

between the changes in resistance of the two coils are directly related to the

concentration of combustible gases.

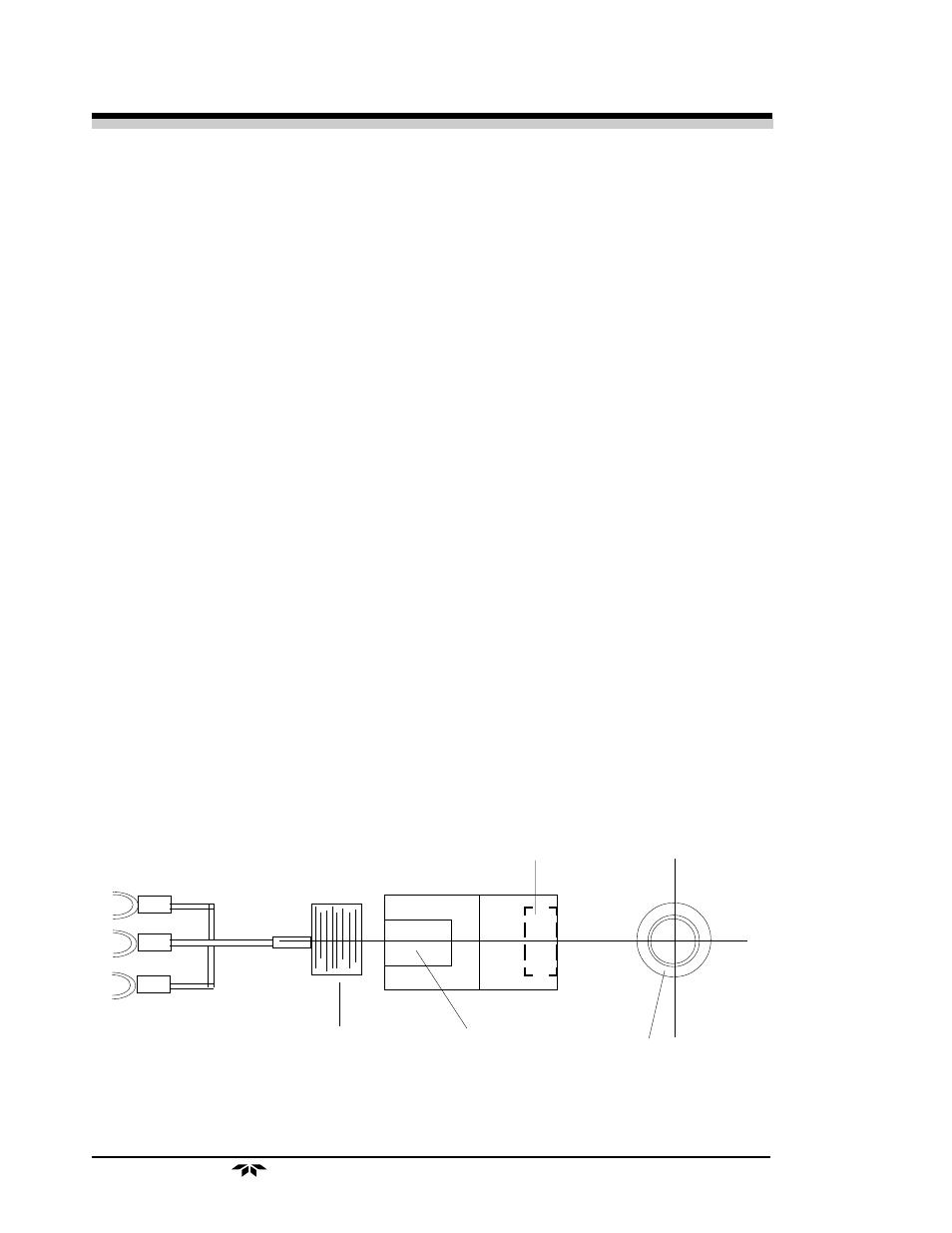

For area monitoring applications, these two beads are installed in a

metal housing as shown in Figure 2-2. Wires connected to the beads are

brought out the back of the detector through potting which provides me-

chanical retention of the wires and provides a gas-tight seal. A stainless-

steel flashback arrestor screen at the front of the detector covers the beads

and is held in place by a retaining cylinder pressed onto the housing. This

retaining cylinder is threaded internally to accept a flow-through adapter

for calibration.

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

123456789

RED

WHITE

BLACK

3/4 NPT

15/16” WRENCH FLAT

PROBE SENSING

SURFACE

INTERNAL THREAD FOR

CALIBRATION ADAPTER

Figure 2-2 Remote Combustible Probe