SPP Pumps Transformer Oil Pumps User Manual

Page 6

Manual No/Rev

W61-001E / 9

Operators Instructions for

Transformer Oil Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications without giving notice.

Page 4

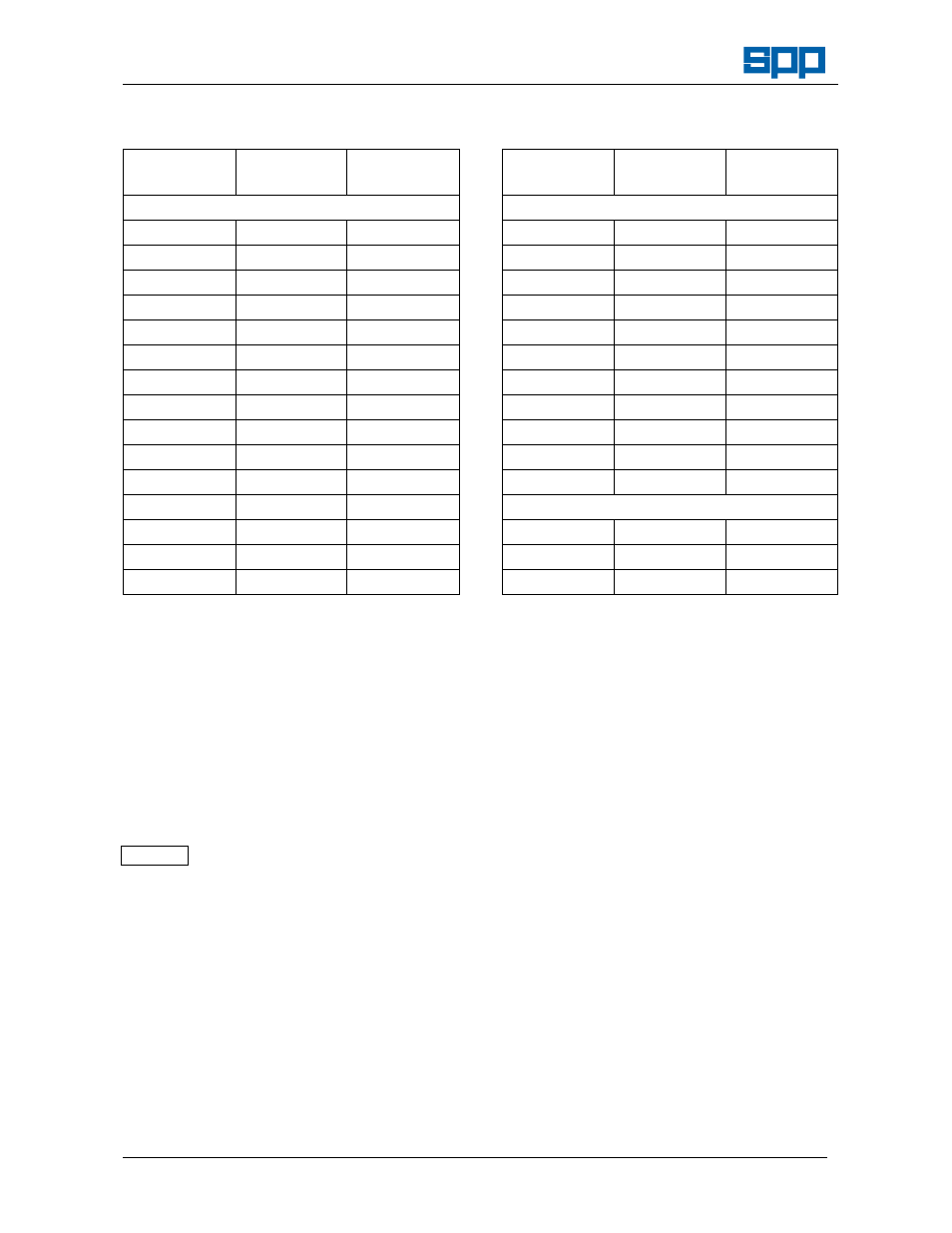

The following table gives a guide to approximate pump net weights, without

flange blanks or packaging:

Pump

Type

Frame

Size

Est. Max.

Weight kg.

Pumps for Static Duty

AT02T

U26/15

34

AT04R

U26/15

37

AT04T

U26/15

37

AT04W

U26/15

37

AT06F

U22/10

37

AT06F

U22/14

40

AT06G

U22/14

40

AT06H

U22/10

37

AT06R

U30/22

62

AT08F

U26/12

51

AT08F

U26/22

60

AT08F

U26/30

74

AT08G

U26/26

65

AT10C

U35/18

104

AT10C

U35/22

110

Pump

Type

Frame Size

Est. Max.

Weight kg.

Pumps for Traction Duty

AT02X

U26/20

48

AT03G

U26/26

52

AT03R

U26/26

52

AT03T

U35/28

95

AT03X

U26/26

54

AT03X

U26/20

49

AT03X

U26/15

45

AT03X

U26/30

61

AT04V

U26/30

75

AT04X

U35/28

90

AT04Y

U35/22

80

Elbow Pumps

AT06T

U41/24

250

AT09R

U41/24

250

AT10T

U48/36

430

2.3

Storage

2.3.1

Temporary Storage

If the pump unit is not used immediately store it carefully in a sheltered, dry

location with as uniform a temperature as possible. It must be completely

isolated from vibration. Preferably store the unit in the vertical position.

Ensure that the unit is sufficiently well chocked that it presents no risk either

to the pump itself or to people nearby.

Do not remove the covers fitted to the pipe flanges until immediately

before connection. These provide protection from the ingress of dirt. It is

essential that the pump remains absolutely clean internally.

2.3.2

Long Term Storage

For storage longer than 3 months, or where abnormal conditions prevail, e.g.

adverse environments, damp, corrosive atmospheres, vibration or other

physical forces etc., please refer to SPP Pumps Limited.

ATTENTION