Safety guidelines, Specific information, Portion control – Server SE-xxx EXPRESS User Manual

Page 2

SAFETY GUIDELINES

According to food and safety regulations, most foods

must be stored and/or served at certain temperatures

or they could become hazardous. Check with local food

and safety regulators for specific guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for

the serving of potentially hazardous product.

NSF International

(National Sanitation Foundation)

lists this pump as: “Not acceptable for

dispensing potentially hazardous foods.”

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless

steel. Server Products, Inc. regrets that we can

not honor warranty claims on stainless steel

parts that have been affected by sauerkraut

or Aus Jus.

SPECIFIC INFORMATION

Drop-In Units

Drop-In units can be used either on a counter top surface

or can be dropped into an opening in a counter top.

Model Number

Recommended

Counter Top Opening Size

07000, 07020

8 1/2” x 6 3/8”

07010, 07030

8 1/2” Diameter

07050

8 1/2” x 16 3/8”

07210

8 1/2” x 21 13/16”

07070

8 1/2” x 27 3/16”

07160

8 1/2” X 11”

Parts for 07000 and 07010:

If part information is needed for model numbers

07000 or 07010, prior to Series 97K,

contact Server Products customer service department.

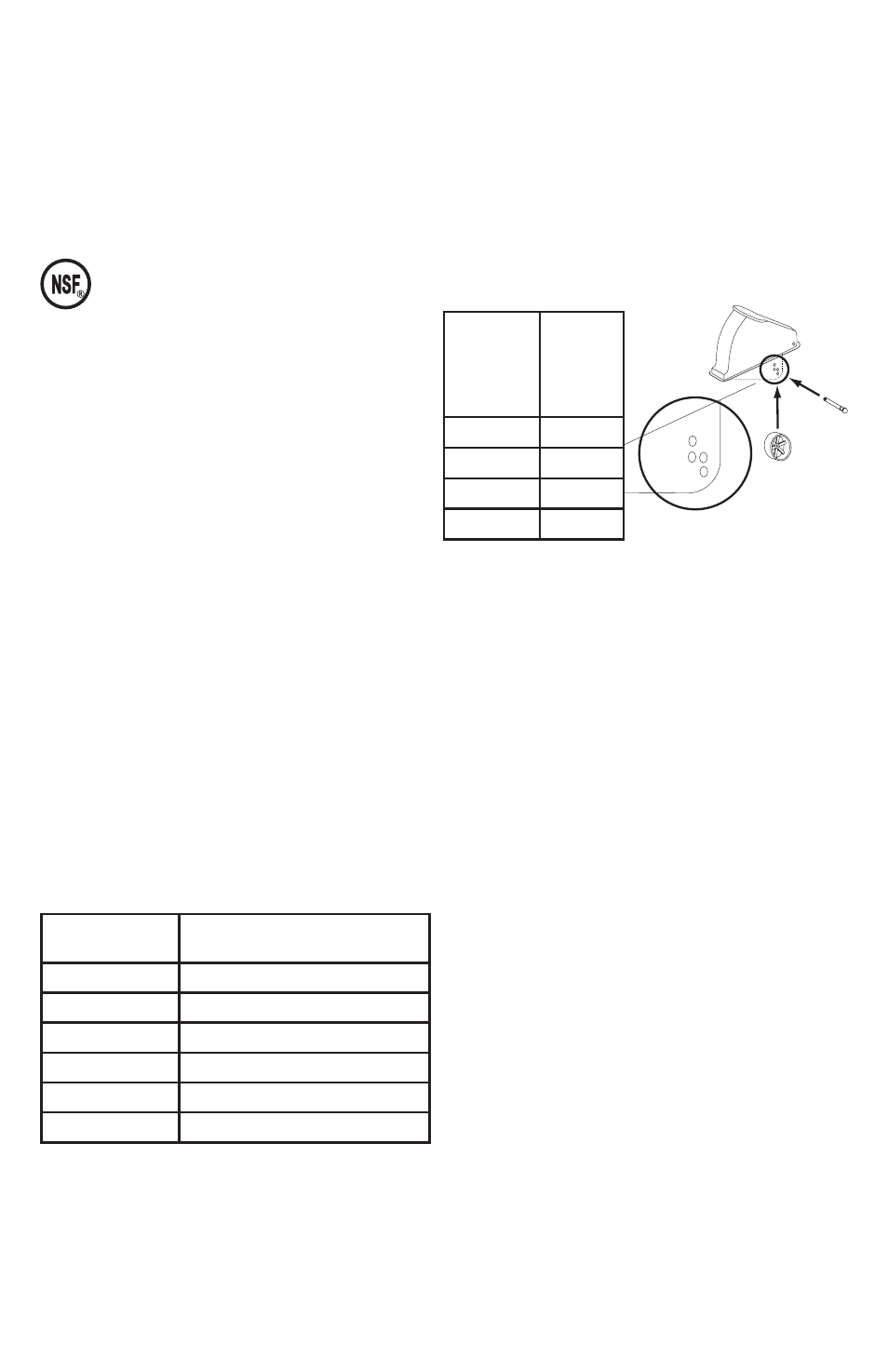

PORTION CONTROL

Portion control is the amount of product which will

dispense from pump with each full push of lever.

The roller, which is attached to the bottom of the lever,

can be adjusted to allow for specific portion control.

How to Set Portion Control

1

REMOVE LID FROM UNIT.

2

REMOVE ROLLER FROM LEVER BY PULLING

HINGE PIN OUT.

3

DETERMINE WHICH PIVOT HOLES IN LEVER WILL

BE USED TO HOLD ROLLER FOR PORTION

DESIRED PER FULL PUSH OF LEVER.

Portion

Desired

(per full

push of

lever)

Adjust

roller

to pivot

on lever

holes

1 Ounce

A

3/4 Ounce

B

1/2 Ounce

C

1/4 Ounce

D

4

ALIGN CENTER HOLE OF ROLLER WITH SELECTED

PIVOT HOLES ON LEVER.

5

INSTALL HINGE PIN THROUGH SELECTED PIVOT

HOLE ON ONE SIDE OF LEVER, THROUGH CENTER

HOLE OF ROLLER, AND THROUGH COORDINATING

PIVOT HOLE ON OTHER SIDE OF LEVER.

• Push hinge pin through until it securely snaps

into place.

6

INSTALL LID ONTO UNIT.

D

B

C

A