Maintenance – Fulton Hopkins (HPN) Horizontal Coil Thermal Fluid (hot oil) Heater User Manual

Page 73

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 4

HPN-IOM-2014-0416

MAINTENANCE

4-13

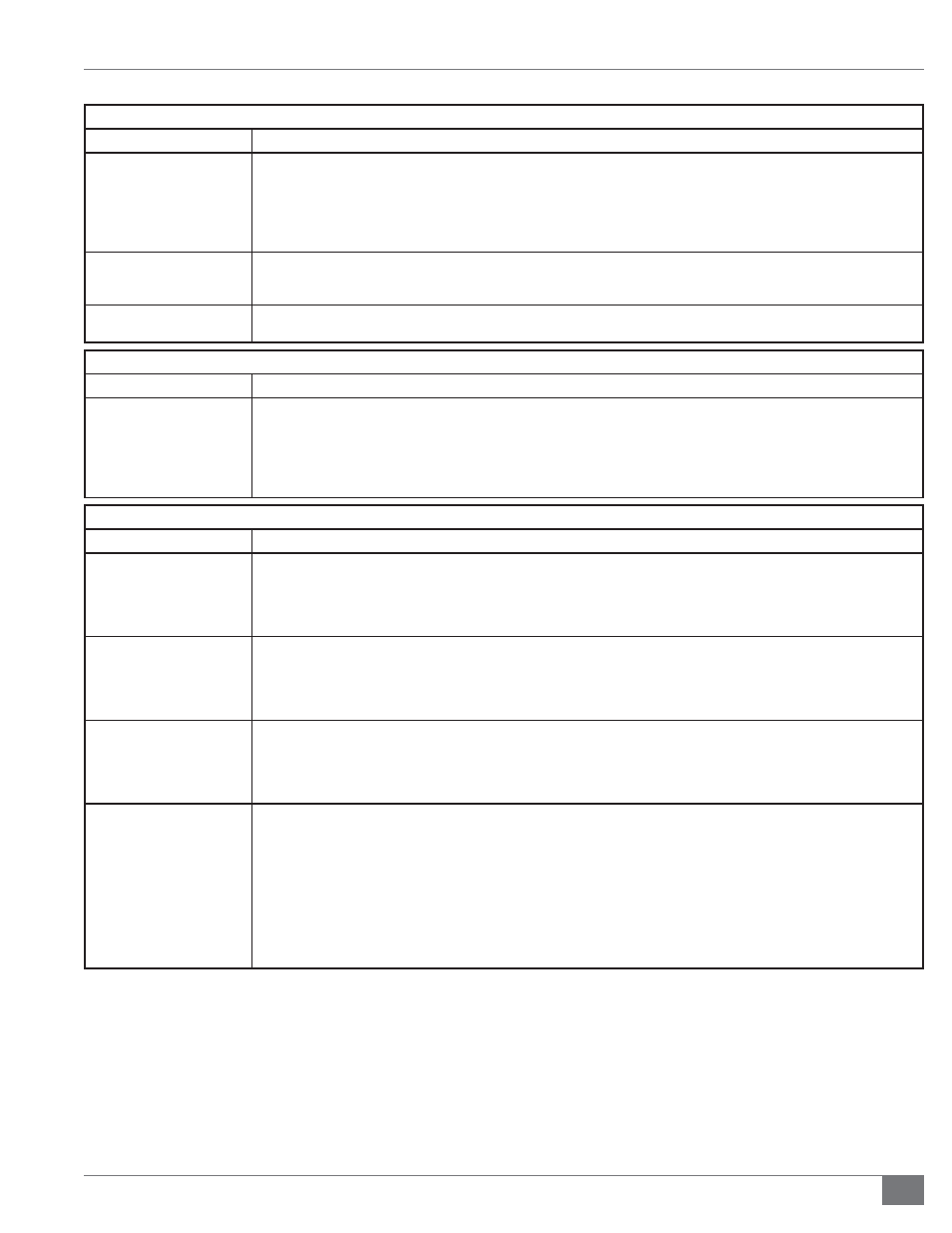

TABLE 10-D - HIGH INLET PRESSURE SWITCH TROUBLESHOOTING

Problem

Potential Remedy

An obstruction downstream of

the heater

Any obstruction downstream of the heater will increase the pressure that the heater outlet sees. This obstruction will generally result

from an improper valve setting.

Observe heater outlet pressure at temperature with all users / heat exchangers calling for heat (100% user). Observe heater outlet

pressure at temperature with all users / heat exchangers not calling for heat (100% bypass).

Bypass regulating valve(s) should be adjusted to equal fl ow condition through users. Call or e-mail Fulton for further details.

It may be possible that an automatic control valve has failed. If this is the case, the valve should be replaced.

Plugged Coil Pipes

If too low of a fl ow condition has occurred for too long a period of time or if the maximum operating temperature of the oil has been

exceeded, it is possible, however unlikely, that a pipe or pipes in the coil could plug with solids. If this occurs, it will be necessary to

shut down the system and clean the coil. Fulton Thermal Corporation should be consulted in this matter.

Improper Switch Setting

The High Inlet Pressure Switch should be set at 25 psi above the heater inlet pressure when the system is cold. At no time should

the switch be set above the safety relief valve set pressure.

TABLE 10-E - DIFFERENTIAL PRESSURE SWITCH BREAK TROUBLESHOOTING

Problem Potential

Remedy

An obstruction downstream of

the heater outlet

Any obstruction downstream of the fl ow switch(es) will increase the pressure that the heater outlet sees. Any increase in outlet

pressure will result in diminished fl ow. This obstruction will generally result from an improper valve setting.

Observe heater outlet pressure at temperature with all users / heat exchangers calling for heat (100% user). Observe heater outlet

pressure at temperature with all users / heat exchangers not calling for heat (100% bypass).

Bypass regulating valve(s) should be adjusted to equal fl ow condition through users. Call or e-mail Fulton for further details.

It may be possible that an automatic control valve has failed. If this is the case, the valve should be replaced.

TABLE 10-F - CALL FOR HEAT CIRCUIT TROUBLESHOOTING

Problem

Potential Remedy

Programming Problem

Fulton has a general program for each of the temperature controllers we have used over the years. Compare your

current temperature controller program to Fulton’s general program.

See the back of this section for general programming sheets for standard Fulton heaters.

Make changes as necessary. Contact Fulton service department with any questions.

Temperature Controller

Failure

If the temperature controller is calling for heat but is not putting power on the output to the control relay, the relay

will not close the normally open contacts and the heater will remain disabled. If this is the case, some controllers

have separate sets of contacts that may be utilized in replacement of the damaged contacts. Some rewiring and/or

reprogramming will be needed. Contact Fulton service department if necessary.

Temperature Sensor

Failure

Diff erent temperature controllers use diff erent types of temperature sensors. These may be Type J thermocouples,

RTDs or another type of sensor. It is possible for these sensors to malfunction. To verify proper sensor operation, use

an alternate source of temperature detection such as an infra-red temperature sensor to sense temperature at the

same point.

Control Relay May Have

Failed

Many temperature controllers energize a relay with a call for heat that in turn closes a normally open set of contacts to

energize the burner circuit.

If your temperature controller is sending an output signal to the control relay but the burner is not initiated, check

resistance across coil of the relay. An open reading indicates that the relay needs to be replaced. If the coil shows

resistance, energize coil and check contacts. With coil energized, normally open contacts should close resulting in a

reading of control voltage on both the common and normally open contact.

If voltage exists on common but not on normally open contact either switch contacts if another set of normally open

contacts are available or replace relay.