Operation, Gas pressure switch – Fulton Hopkins (HPN) Horizontal Coil Thermal Fluid (hot oil) Heater User Manual

Page 53

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 3

HPN-IOM-2014-0416

OPERATION

3-21

!

WARNING

Do not operate, or allow others

to operate, service or repair this

equipment unless you (they) fully

understand all applicable sections

of this manual and are qualifi ed to

operate/maintain the equipment.

Non-Fulton product information is for

reference purposes only. No Fulton

document may substitute for full

review of documentation available

from the component manufacturer.

3. Repeat for each switch; replace covers. Note, if the burner was on, it would

also stop.

4. To set the low fl uid pressure cutout switch, raise the setpoint with the fl uid at

operating temperature and pump running, until the pump shuts down. Note

the setpoint and lower by 10 PSI, then re-start pump. The setpoint at cutout

should correspond to the reading on the output pressure gauge.

5. With the unit cold and pump running, lower the high fl uid pressure cutout

switch until the pump shuts down. Note the setpoint and raise by 10 PSI, then

re-start pump. The setpoint at cutout should correspond to the inlet gauge

reading.

Gas Pressure Switch

NOTE:

Gas Fired Units Only

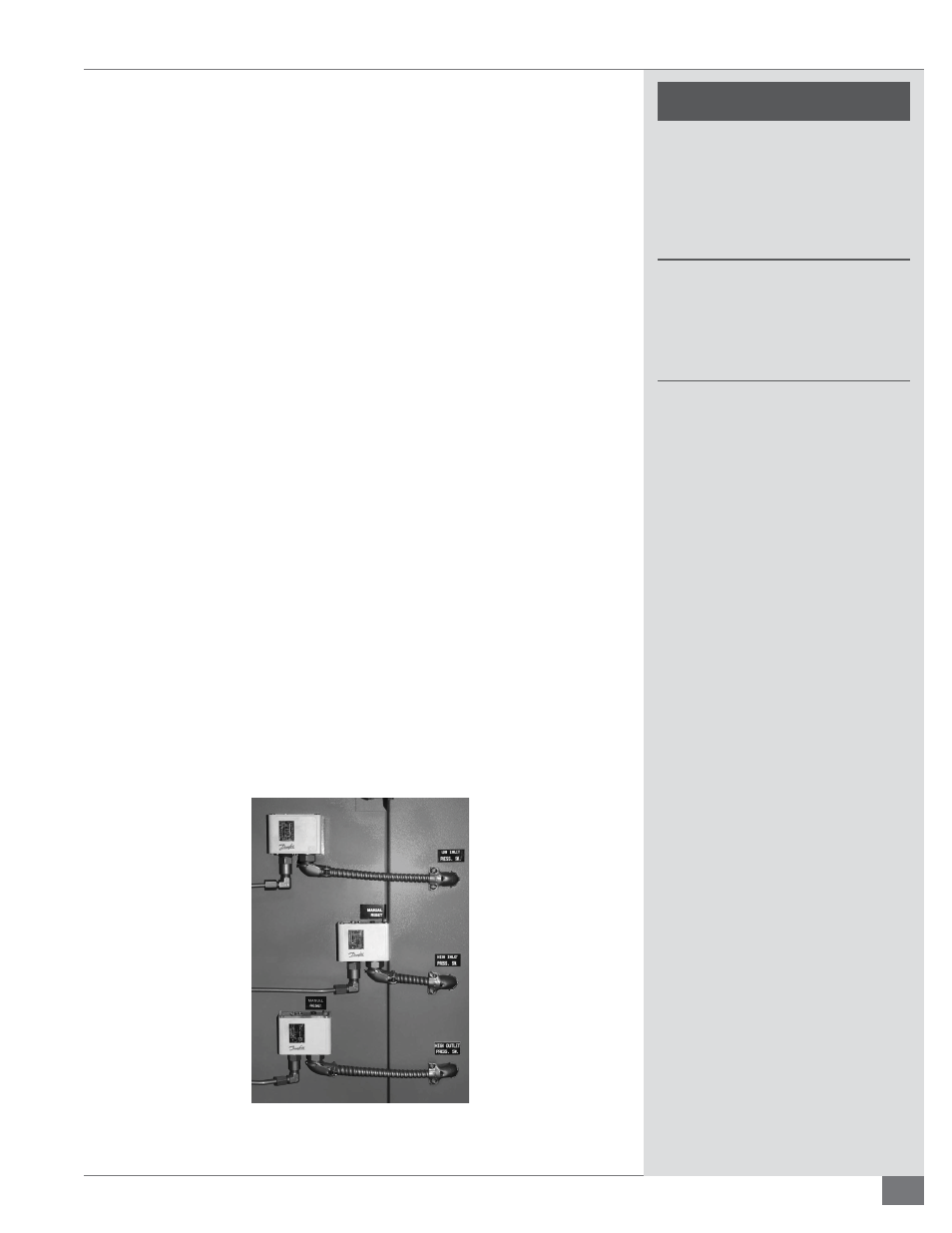

The high and low gas pressure switches are located on the gas train. See Figure

14. The switches are used to ensure that the incoming gas pressure and gas

pressure to the burner are within the appropriate range.

1. While

fi ring, shut the main gas ball valve.

2. Unit will lock out on high gas pressure.

3. Attempt restart by resetting fl ame programmer.

4. Unit will start purge and lock out.

5. Open the gas valve closest to the burner and reset fl ame programmer.

6. Reset high side of switch, unit will start purge and fi re.

7. To test the low gas pressure switch, close the incoming manual valve.

8. Allow the control to sequence.

9. When the gas valves energize, the heater should lock out.

FIGURE 13 - PRESSURE SWITCHES