Installation, Feed water blowoff piping, Blow off valve – Fulton Electric (FB-L) Steam Boiler User Manual

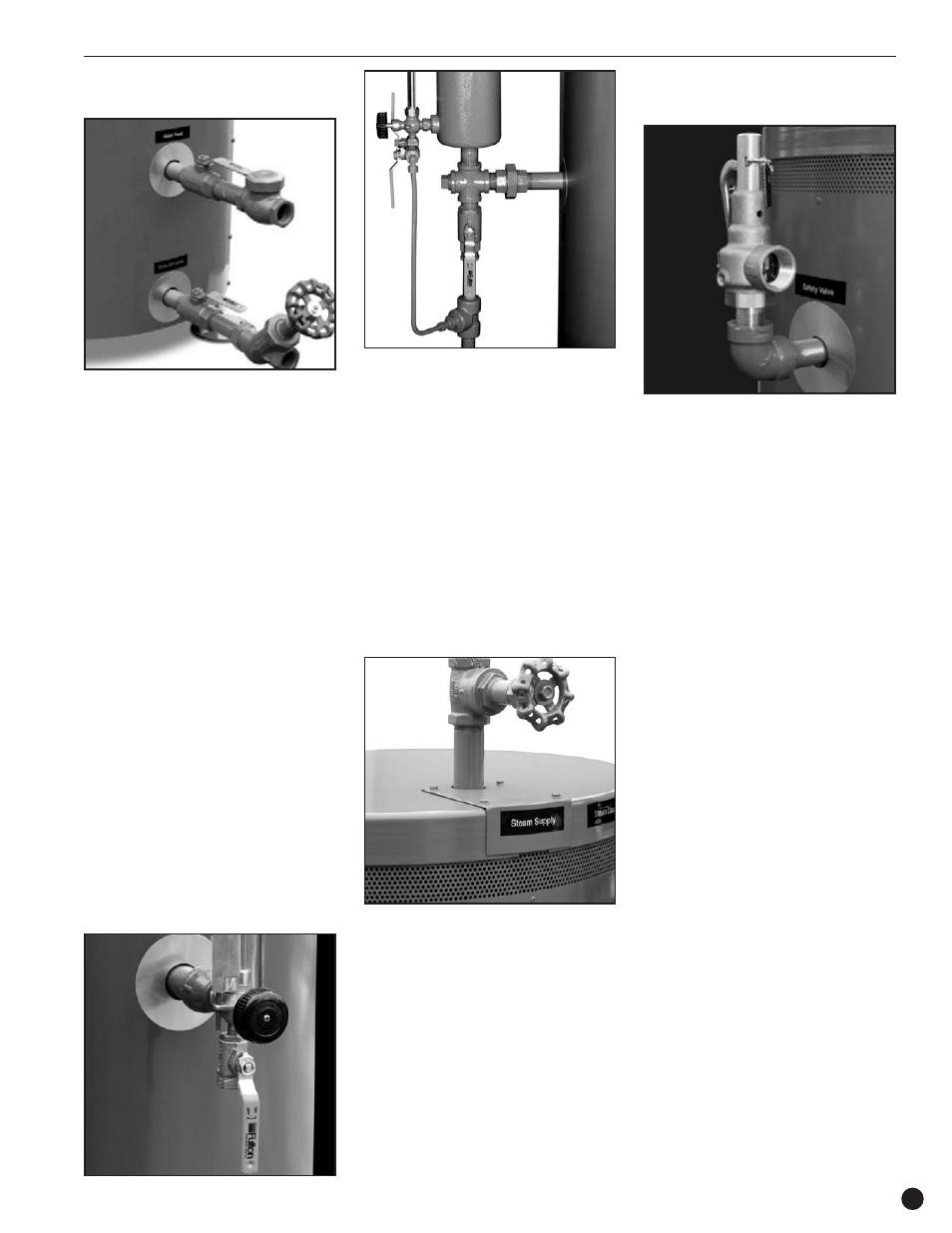

Page 17: Main steam valve

Electric IOM

Installation

13

Feed Water Blowoff

Piping

Connect the feed water stop valve to the

opening over the blow- off at the rear of the

boiler and pipe it to the return system. If the

city water pressure exceeds 40 lbs., a

pressure reducing valve should be installed

ahead of the return tank.

NOTE

Where a condensate return tank is to be

fitted, this should:

1. Be vented and

2. Have a capacity sufficient to satisfy

boiler consumption as well as

maintain proper return tank

temperature.

3. Vent pipe should not be down-sized

(This may cause pressure build up in

the condensate tank.

Blow Off Valve

There are three blow off valves on the

boiler; the 2 main valves at the rear of the

boiler and the water gauge glass blow off

valve. The 2 boiler blow off valves supplied

with the boiler should be screwed to the

blow off pipe at the rear of the boiler and

connected to a blow off receptacle of

approved design piping. All these

procedures should be done in

accordance with state and/or local

codes.

The water gauge blow off valve should

be connected to the main blow off line.

NOTE

Care should be taken to ensure that the

blow off receptacle used meets the

regulations covering such vessels. If in

doubt consult a Fulton Representative

for advice.

Main Steam Valve

Insert the main steam valve in the steam

supply line as close as possible to the boiler

and prior to any of the steam using

equipment, ensuring correct steam traps

are used.

Steam Safety Valve

1. Before installing, be sure that all steam

pip es and connections have been blown

clean; pipe compound or dope is used

on external threads only; and inlet of

valve is free of any foreign material.

2. When making installation, use proper

type and size wrench .

3. The valve should be installed in a vertical

upright position in the connection

provided with no unnecessary

intervening pipe or lining. Under no

circumstances should there be a shut off

valve or restriction of any kind between

the safety valve and the boiler

connection provided.

4. Do not cap or plug drain hole in the side

of valve body.

5. Since the purpose of this safety valve is

to protect against an overpressure

situation, it will loudly discharge hot

steam in doing so. Therefore, it is

recommended that a discharge pipe be

securely installed and run to a safe point

of disposal.

6. When a discharge pipe is used, it must

be of a pipe size equal to or greater than

that of the valve outlet. Use schedule 40

discharge pipe only. Do not use

schedule 80, extra strong or double

extra strong discharge pipe or

connections. It must be as short and

straight as possible and so arranged as

to avoid undue stress on the valve. It

must have an ample provision for

draining condensate at or near the valve

outlet. It must terminate freely to

atmosphere with no intervening valve of

any description and it must be securely

anchored and supported.

CAUTION

Do not downsize piping below safety

valve size.

CAUTION

Unless otherwise specified, the steam

safety valve supplied with the boiler is

pre-set. This valve is provided as a

safety device for the boiler and should

not be used as the sole protection for

other equipment using steam from the

boiler. Do not tamper with the setting (It

could accidentally be set at a pressure

higher than the design pressure of the

boiler, and therefore create a hazardous

condition.