Troubleshooting powerhook – Poweramp POWERHOOK SERIES User Manual

Page 42

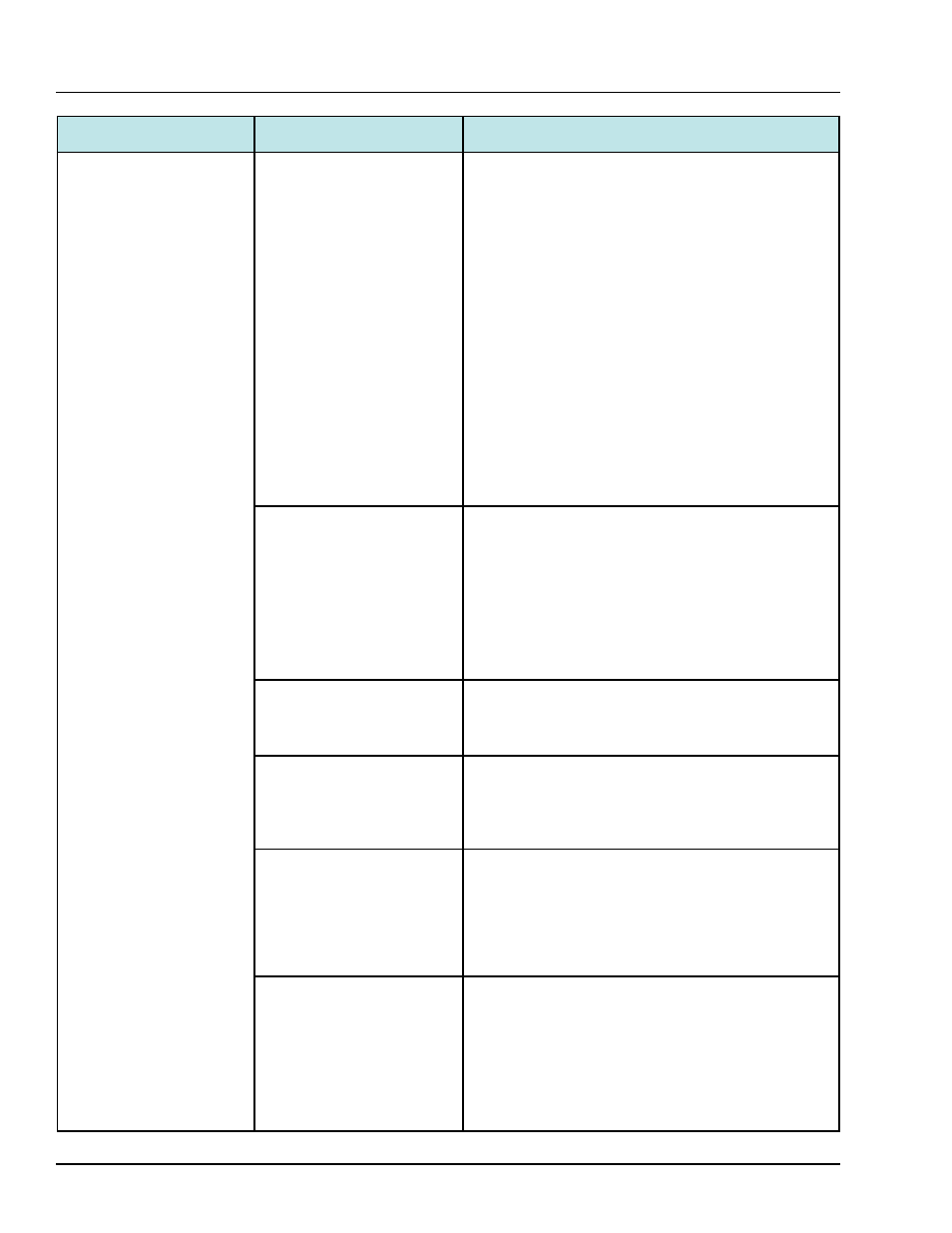

TROUBLESHOOTING POWERHOOK

Symptom

Possible Cause

Solution

Restraint does not

lower at all from

stored position. Pump

operates in pressure

relief (restraint does not

extend).

Solenoid “D” valve stuck off. Locate solenoid (See Parts: Valve Block).

Remove coil from cartridge valve and cartridge valve

from valve block.

-Check valve for contaminant’s and/or damage.

-Replace valve if damaged.

-Carefully wipe valve with clean rag (do not damage

“O” rings on valve).

-Check valve block for contaminant’s.

-Replace valve and coil.

NOTE: Do not over tighten valve into block. Max Torque:

30-40 lb/ft. or snug to prevent leakage. Tighten coil snug,

avoid over tightening and causing valve to bind.

Operate unit. Replace valve if problem persists and

all other troubleshooting procedures performed.

Solenoid “D” coil not

receiving signal to energize.

A solenoid that is energized

will act like a magnet.

Place a metal tool on coil of

solenoid valve to determine

if coil is receiving signal.

1. Check controller output that sends a signal to

solenoid. Output may have failed OPEN. Use

meter to check for contact closure when output

ON.

2. Check all wiring to solenoid for high resistance

(loose) or no connection.

Solenoid “D” coil receiving

signal but not energizing.

Coil failed OPEN. Consult factory for replacement.

Obstruction preventing the

restraint from lowering.

Remove obstruction, check for damage to

components.

Fluid flow to positioning

cylinder blocked.

Locate the needle valve that controls fluid flow to the

cylinder. (Hook valve block has two needle valves,

adjust valve adjacent to NV stamped in valve block)

Turn valve out all the way counter clockwise. Turn

valve in all the way clockwise. Turn valve out 1-1/2

turn counter clockwise.

Binding inside positioning

cylinder.

Locate the positioning cylinder and the hook

weldment. Pushing down on the hook weldment

should extend the positioning cylinder and releasing

the weldment should allow the positioning cylinder to

retract. Consult factory if this does not occur.

4111-0010 — Nov 2010

40