Perrycraft SportQuest Upgrade - Flush Mount Slotted Track User Manual

Perrycraft For the car

Stanchion Assy.

Button-Head

Machine Screw

Crossbar

Track

Tap

Plate

Stanchion

Bracket

(OVER)

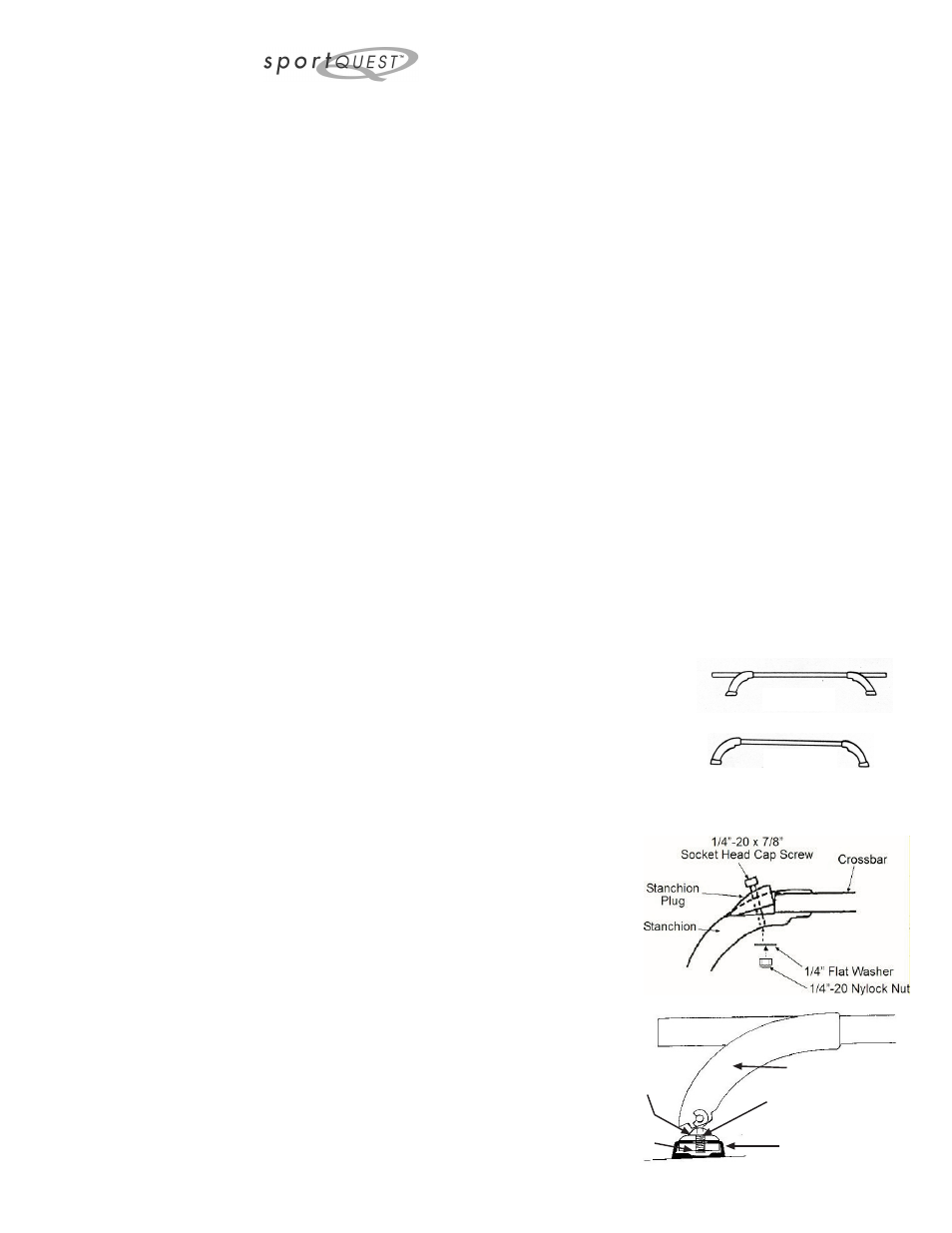

Fig. 1

Fig. 2

INSQ-UPGD-TS Page 1 of 2 120918

UPGRADE BAR SYSTEM

To Be Used With OE Flush-Mounted OE "Slotted" Track-Style Roof Racks

WARNING: External roof racks do not increase the GVWR of the vehicle. Maximum load for this bar system is

180 lbs. evenly distributed on crossbar assemblies. Keep in mind that torque applied to any straps, cords, etc.

between the load and the vehicle body effectively add "load weight" to crossbars and the roof. Large or flat items

such as plywood or watercraft can trap air and create wind lift. Secure the ends of such objects directly to the vehicle

bumpers or tie downs. Bulky or tall loads can create tremendous horizontal wind resistance from headwinds and

crosswinds. Extreme caution should be used when transporting such loads, taking into consideration road conditions,

vehicle speed, crosswinds, load securing methods, etc. Large, bulky, tall or flat objects should be properly secured

to both crossbars and other attachment points on the vehicle body. Check bar adjustment points and load securement

frequently. PERRYCRAFT, Inc. does not assume responsibility for improper installation, exceeding load limit, load

securement methods, vehicle roof strength, wind lift or any other factors beyond its control. All fasteners, knobs,

and load securements should be checked frequently and tightened as necessary.

For technical assistance, please contact PERRYCRAFT, INC. at 800-777-7081.

IMPORTANT NOTE: The enclosed Warranty/Consumer Information card must be fully completed by installation

center and reviewed with the consumer (end-user), and given to the consumer. In the event of a potential warranty

issue, failure by the consumer to provide Mfg. with a copy of the completed document will void warranty coverage.

CONTENTS: 2-Crossbars; 4-Stanchion assemblies; 1-Hardware Pack (4 each: Crossbar End Plugs, 3/16" Drive

Rivets, Stanchion Plugs, 1/4"-20x7/8" Socket-head cap screws, 1/4" Flat Washers, & 1/4"-20 Nylock Nuts; 8 each:

1/4"-20 x 1/2" Allen Button Head machine screws, Tap Plates, Foam Spacers; 1 each: 5/32" & 3/16" Allen wrenches;

1-Instruction Sheet; 1-Warranty/Consumer Information card).

TOOLS REQUIRED: Tape Measure, Hand Drill, 3/16" Drill Bit, Flat-head Screwdriver, Hammer, Non-permanent

Marker, 7/16" Wrench or Adjustable Wrench, and Metal-cutting Saw (if option 2 is chosen).

NOTE: Original Equipment crossbars may be removed or left intact as desired.

This "Pass-Thru/Stanchion-Fit" upgrade kit provides the choice of two configurations of the stanchions and crossbars

at the time of installation:

OPTION 1: Pass-Thru Crossbars: Extend the crossbars through the stanchions:

OPTION 2: Stanchion-Fit Crossbars: Cut the crossbars to the appropriate

length to provide exact fit between the stanchions

IMPORTANT: Completely review the instructions for chosen option before proceeding with installation!!!

OPTION 1 - Pass-Thru Crossbars:

1. Install stanchion plugs into two stanchions using 1/4"-20 x 7/8" cap

screws, 1/4" flat washers and nylock nuts as shown in Fig. 1.

2. Slide one "plugged' stanchion on to one end of each crossbar, butting

end of bars firmly against stanchion plugs. Slide remaining two "open"

stanchions on to opposite ends of bars positioning both stanchions

relative to width of existing tracks.

3. Insert 4 diamond-shaped tap plates into each track by tilting plates at

an angle and dropping into open slot in track (See Fig. 2). Note: If the

slots in the tracks are deeper than 3/8" the self-adhesive foam

spacers should be attached to the bottom of each tap plate. If slot

in track is too narrow or shallow to accept plates in this manner, it

will be necessary to remove the molded end cap at one end of each

track and slide the tap plates into the tracks. If this procedure is used,

it may be necessary to re-seal around screw in end cap when

reinstalling.