Perrycraft SportQuest Pad Mount - Fiberglass User Manual

Roof rack

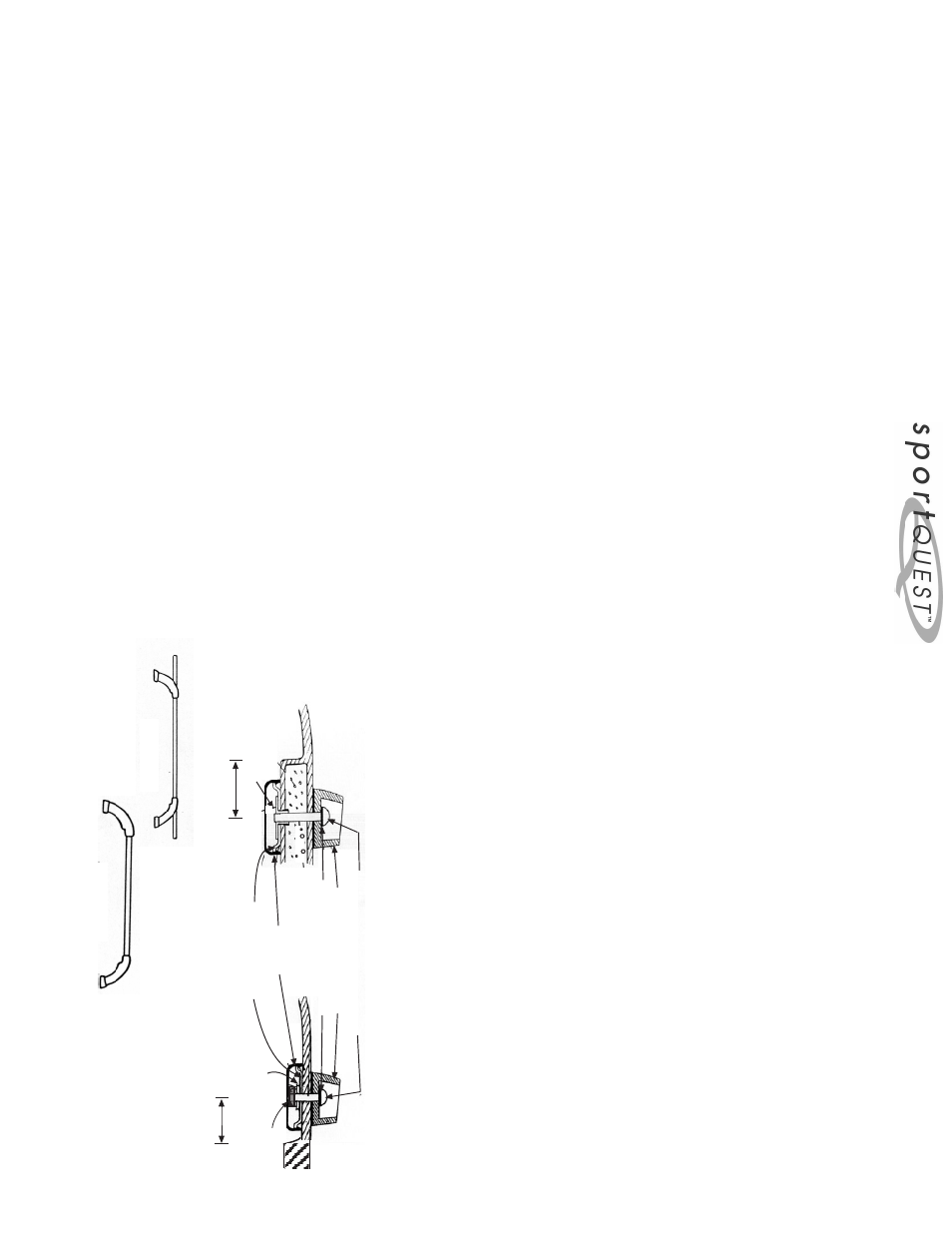

Mounting Pad

Neoprene W

asher

#10-24 x 1 Machine Screw

Cor

e Mounting

Single Layer Mounting

Propeller T

ee Nut

Retainer W

asher

Cover

S. Steel Flat

W

asher

Lock Nut

Min. 1 from

Edge of Core

Min. 1 from

Edge of Core

(OVER)

INSQ-PMOP-OE Page 1 of 3

120918

Roof Rack

Pad Mount with Optional "Pass Thru/Stanchion Fit" Hardware

Fiber

glass or Composite Material Roof Installation

W

ARNING:

Do not use sheet metal screws to attach roof racks to fiberglass or composite material roofs!

External roof racks do not increase the GVWR of the vehicle.

Maximum load for this rack is 180 lbs. evenly distributed on crossbar assemblies. Keep in mind that torque applied to any straps, cords, etc. between the load and the vehicle

body ef

fectively add "load weight" to crossbars and the roof. Lar

ge or flat items such as plywood or watercraft can trap air and create wind lift. Secure the ends of such objects

directly to the vehicle bumpers or tie downs. Bulky or tall loads can create tremendous horizontal wind resistance from headwinds and crosswinds. Extreme caution should

be used when transporting such loads, taking into consideration road conditions, vehicle speed, crosswinds, load securing methods, etc. Lar

ge, bulky

, tall or flat objects should

be properly secured to both crossbars and other attachment points on the vehicle body

.

PERR

YCRAFT

, Inc.

does not assume or accept responsibility for style or size of rack

installed, improper rack installation, exceeding rack load limit, load securement methods, vehicle roof strength, wind lift or any other factors beyond its control.

All fasteners,

knobs, and load secur

ements should be checked fr

equently and tightened as necessary

.

For technical support, please contact Perrycraft, Inc at 800-777-7081.

IMPOR

T

ANT NOTE

: The enclosed W

arranty/Consumer Information card must be fully completed by installation center and reviewed with the consumer (end-user), and

given to the consumer

. In the event of a potential warranty issue, failure by the consumer to provide Mfg. with a copy of the completed document will void warranty coverage.

A

TT

ACHMENTS:

PERR

YCRAFT

, Inc. of

fers a wide range of Sports Equipment Carriers (ski, snowboard, surfboard, sailboard, bicycle, canoe, kayak, etc.), general-purpose

load brackets, car

go baskets, and load securement straps. Contact your

PERR

YCRAFT

Distributor or our Customer Service Department at 800-777-7081.

CONTENTS:

2

Crossbars,

4/ea.

, Stanchion Assemblies, Pad Assemblies;

1-

Hardware Pack (

12/ea.

1/4 Stainless Steel Flat W

ashers,

8/ea.

#10-24x1 Pan-head machine

screws, M6x12mm Socket Head Cap Screws, #10-24 Lock Nuts, #10-24 Propeller T

ee Nuts, #20 Shoulder W

ashers, #20 Snap-on Screw Covers, 3/16x3/8x1/32 Neoprene

W

ashers;

4/ea.

Crossbar End Caps, Stanchion Plugs, 1/4"-20x7/8" Socket Head Cap Screws, 1/4"-20 Lock Nuts, Pad Clamp Blocks, 3/16" Drive Rivets,

1/ea.

M5 Allen

W

rench,

3/16"

Allen

W

rench, Instruction Sheet,W

arranty/Consumer Information Card.

T

OOLS REQUIRED:

T

ape Measure, Hand Drill, 3/16 Drill Bit (2 or longer), 9/32 Drill Bit, ¼ Drill Bit, Non-Permanent Marker

, Phillips Head screwdriver

, Flat Head

Screwdriver

, Pliers, Adjustable W

rench, Hammer

, and Metal cutting saw (if option 2 is chosen).

IMPOR

T

ANT NOTE:

For roofs exceeding 1 in thickness, substitute proportionately longer stainless machine screws for the 1 screws furnished. For installation on roofs

without a sandwiched core (corrugated, honeycomb, etc.), for mounting outside the core area, or mounting in any fiber

glass roof less than ½

thick, substitute #10-24 lock nuts and 1/4 Stainless Steel flat washers for propeller tee nuts (see illustration below).

PRE-ASSEMBL

Y

: Prior to assembling rack, measure the size of the core area of the roof.

If mounting inside the core area, stanchions should be positioned so that

mounting hardware penetrates the core a minimum of 1 in from edges

of core. If mounting outside the core area, position so that mounting

hardware penetrates a minimum of 1 outside edges of core.

This "Pass-Thru/Stanchion-Fit" model pr

ovides the choice of two configurations of the stanchions and cr

ossbars at the time of installation.

Option 1

. Pass-Through Crossbars: Extend the crossbars through the stanchions:

Option 2

. Stanchion-fit Crossbars: Cut the crossbars to the appropriate length to provide exact fit

between the stanchions:

IMPOR

T

ANT NOTE T

O INST

ALLER: For Option 1, pr

oceed to Page 2 (over) of this instruction sheet.

For Option 2, pr

oceed to Page 3 of this instruction sheet.