Perrycraft Aventura Roof Racks User Manual

Roof rack installation instructions

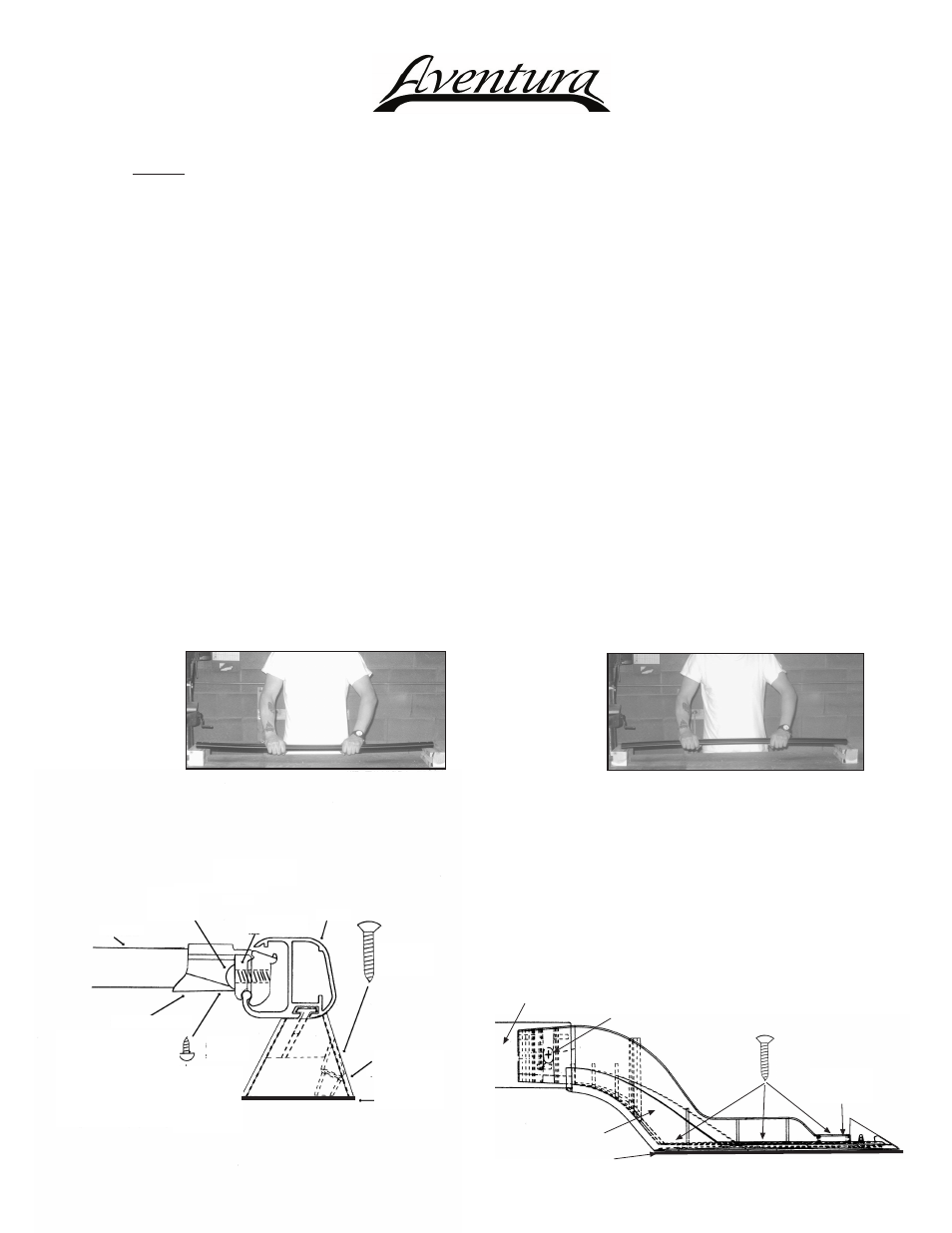

Increase Rail Curvature-Rail Upside Down

Decrease Rail Curvature-Rail Right Side Up

Diagram 2

3) Slide crossbar connectors into opening on inside

of rails as shown in Diagram 1, positioning relatively

equidistant from each end of rails. Loosely tighten

connector lock tab screws using 5/16" allen wrench

provided.

4) Install end supports to side rails using the #8 x 5/8"

self-threading screws as shown in Diagram 2 below.

Do not tighten screws completely at this point.

Crossbar

Crossbar

Connector

1/4-20 x 7/8"

Socket Head

Machine Screw Connector

Lock Tab

Side

Rail

#10 x 1"

Oval-head

Waxed

Screw

Center Post

(when applicable)

Neoprene

Pad

#8 x 5/8"

Screw

#10x3/4

Waxed Screws

#8 x 5/8 Screw

Nylon

Washer

Support Base

(A-R or A-L)

Side Rail

Neoprene Pad

Diagram 1

1/4 S. Steel

Flat Washer

Note: Aventura

racks are designed

with a slot in the underside

of the connectors to enable

rack width to be adjusted to

accommodate a broader range of roof sizes as well as those

roofs having non-parallel body seams and/or rib patterns. The

head of the #8 screw acts as an adjustment stop (re: Step 5

on Page 2 of this instruction sheet).

I N AV- R R K ( P a g e 1 o f 2 ) 1 3 0 8 0 7

Roof Rack Installation Instructions

CAUTION: Do not use the mounting hardware contained in this roof rack kit for installation on Fiberglass or

Composite Plastic surfaces. Supplemental hardware pack, part# HWAVTC-UV, is required for installation on such

non-metal surfaces. Please contact the Distributor from whom the rack was purchased or contact the Perrycraft

Customer Service Dept at 800-777-7081 to obtain the necessary supplemental hardware pack if installing this

roof rack on a Fiberglass or Composite Plastic surface.

CONTENTS: 2 - side rails, 2 - Left end supports and mating covers; 2 - Right end supports and mating covers;

2 - Crossbars; 4 - Crossbar Connector Assemblies; 5 - PVC Roof Slats; 1 hardware pack

containing 8-#8x5/8 self-threading truss-head screws, 12-#10x3/4 waxed-tip pan head screws,

4-1/4 Stainless Steel Flat Washers, 2-Side Rail Center Posts (68" & 78" Rails) or 4-Center Posts

(88" Rails); 2-#10x1 waxed-tip oval-head screws (68 & 78" Rails) or 4-screws (88" Rails); 1-5/16"

Allen wrench; 1-instruction sheet.

Tools required: Phillips screwdriver; electric drill; 1/8 drill bit; center punch; pencil or marker.

1) As a universal roof rack designed to fit several different vehicles, the bow / curvature of the side rails may

or may not exactly match the roof contour of a particular vehicle. NOTE: The rails should be dry fit to

the roof panel before assembling the roof rack. Carefully place one of the rails (without end supports

or center support posts) on the vehicle roof in the approximate location to be installed. The curvature of the

rail should approximate the roof contour. If rail is under-curved and there is more than a 3/16 space between

the ends of the rail and the vehicle roof panel, or over-curved and there is more than a 3/16 space between

the center of the rail and the roof panel, bench adjusting the curvature of the rails is required. Adjust by

suspending the rail between two points (4x4 wooden blocks, two tables, etc). To increase the curvature, start

with the rail upside down; to decrease the curvature, start with the rail right side up (see appropriate illustration

below). With hands spaced shoulder-width apart, apply sufficient pressure to the rail to increase or decrease

the curvature as desired. Repeat this process for both rails.

Important Note: While made of extruded aluminum, the rails are heat-treated for added strength.

Therefore, several applications of adequate springing pressure may be required to modify the curvature

of the rails.

2) Slide center posts into groove on bottom of rails

(applicable only on side rails of 68 or longer) as

shown in Diagram 1 below.

(over)