Sample gas pump, 0 control system, System power – Perma Pure Micro-GASS UG-1212 User Manual

Page 10: Filter temperature control, Dryer temperature control

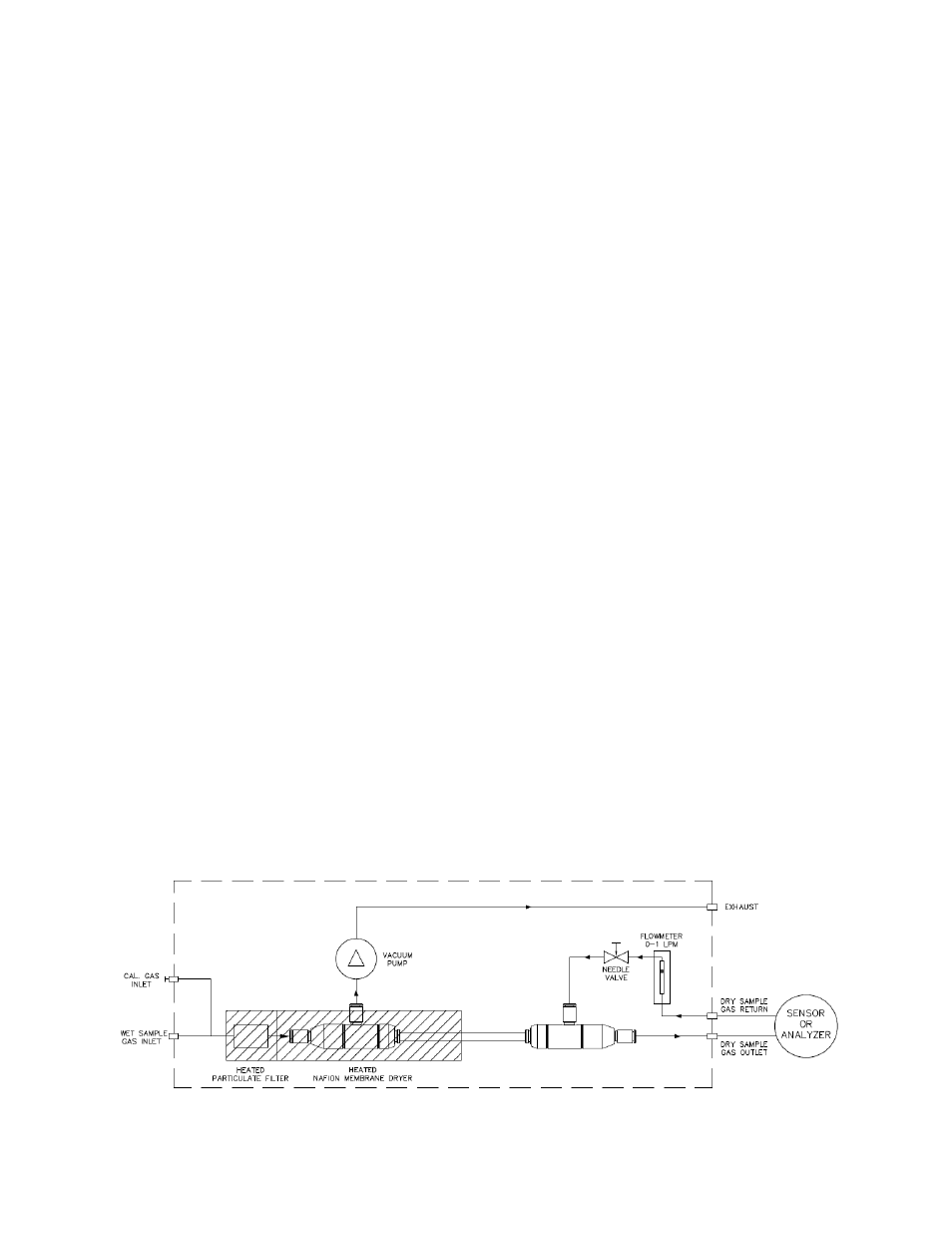

Sample Gas Pump

The sample gas pump draws sample gas from the source, through the dryer and analyzer. By

generating a vacuum in the process, it serves to create the proper conditions for the sample gas

to be used as the purge gas. The pump has a capacity up to 1 lpm and is made from materials

highly resistant to chemical attack.

2.0 Control System

System Power

The system power switch controls power to the temperature controller, filter heaters, and dryer

heaters, System power is on a 2 Amp fuse, located on the control panel. The heated-line

connector is directly connected to the AC power input terminal bock. As a result, the power

switch does not interrupt power to this circuit. There is a 10A inline fuse in this circuit.

Pump Power

Pump power is enabled by the temperature controller when the system reaches the operating

temperature setpoint. With the switch in the ON position, the pump will automatically turn on

when the dryer temperature reaches setpoint. This allows the pump to draw the wet sample into

the system only when the system is ready.

Filter Temperature Control

The particulate filter is thermostatically controlled via a solid state relay and pad style heaters

that are attached to the aluminum housing that surrounds the filter. The setpoint is fixed at 100C

and does not require adjustment.

Dryer Temperature Control

The Nafion® membrane dryer temperature is monitored and controlled by an electronic

temperature controller via a solid state relay and pad style heaters. A type K thermocouple is

used to sense the temperature. The setpoint temperature range is from 35

O

C to 65

O

C.

Flow Control

– Sample gas flow is measured and controlled by a float type rotameter after

it returns to the MicroGASS. The flow meter should be adjusted to provide a flow of between 0.5

to 1.0 lpm for optimal performance of the system.

Figure 1- Flow Diagram

10