Dixon Valve 100 TON RAM SEC05 External Swaged Cam and Groove User Manual

Page 10

100 Ton Ram Instruction Manual

Cam & Groove Holedall Couplings

customer service

800

•

355

•

1991

8

Section 5

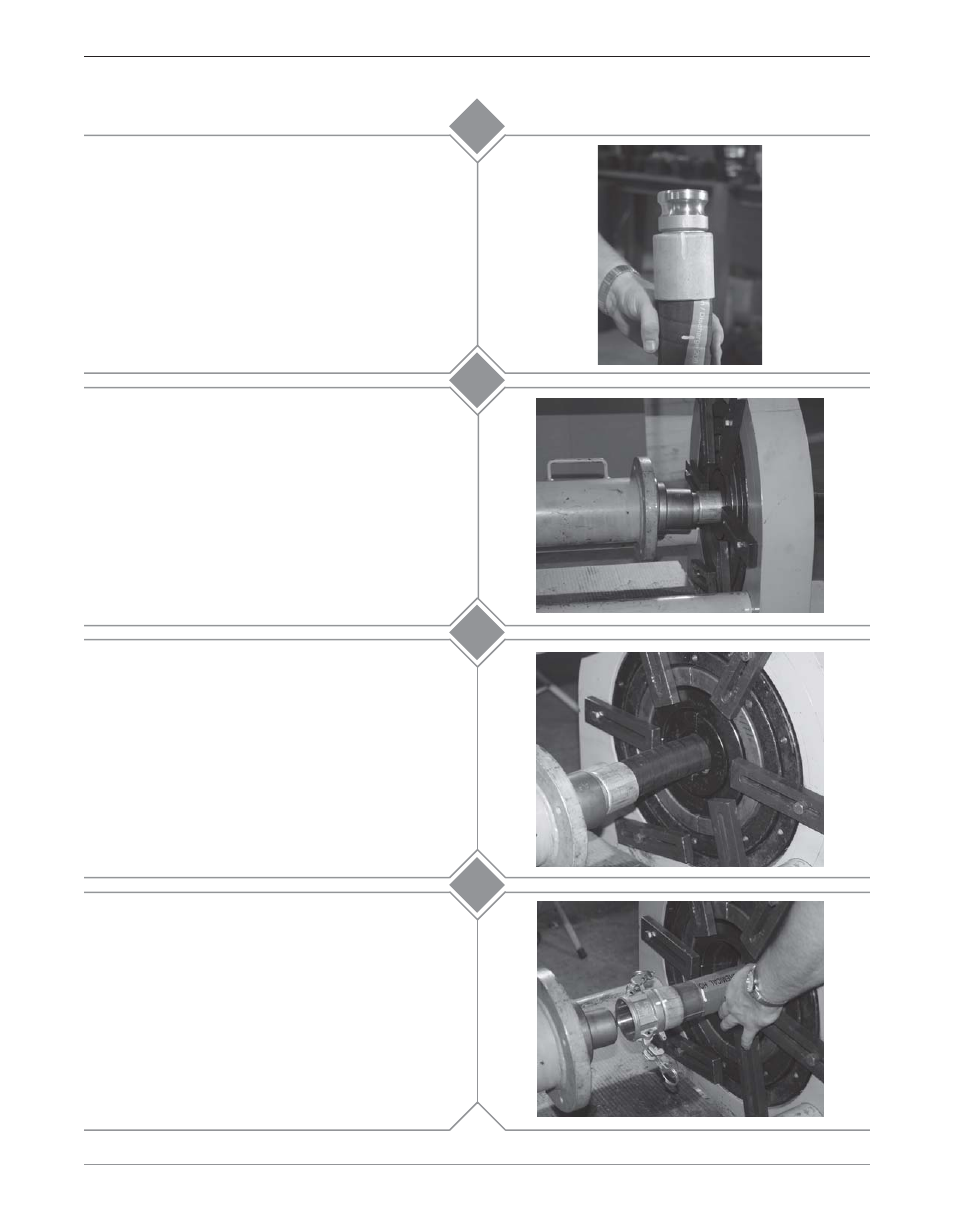

Check the ferrule for proper alignment. Ensure that

the mark on the ferrule (from Step 6b) is in the

center of the stem collar.

Move any tie down bars from the die that may come in

contact with the pusher. While holding the hose and

coupling up against the pusher, depress the button on

the remote. Once the ferrule has started to be reduced

(approximately 1/3 the way) it is no longer necessary for

the operator to hold the hose. Continue the swage until

the pusher contacts the die face. When this occurs,

release the button on the remote and move the

directional control lever to the “NEUTRAL” position.

Move the directional control lever to the

“FORWARD” position. Depress the button on the

remote and advance the cylinder until the end of the

ferrule is near the die opening. Using a wooden

board or metal pipe, lift the ferrule up. Jog the

cylinder by quickly depressing and releasing the

button on the remote. This will allow the ferrule to

enter the die slowly without contacting the die face.

Continue jogging the cylinder until the ferrule has

entered the die approximately 1-1/2"

Move the directional control lever to the “REVERSE”

position. Depress and hold the button on the remote

retracting the cylinder until there is sufficient room

for the stem and ferrule to clear the die bed.

For “E” style couplings:

Note: If the gauge reads 10,000 PSI before swaging

is complete, stop. The ferrule or die used for that

hose end may be incorrect. Contact Dixon for

further assistance.

13c

13d

13a

13b