Dixon sanitary quick weld ferrules – Dixon Valve Newsletter:February:Search:Safety User Manual

Page 2

FA L L

/

W I N T E R

2013

ᔢ

BOSS

35

W W W

.

D I XO N VA LV E

.

C O M

A crew had been in the midst of its

normal routine. One man held the hose

and poured the concrete while the other

two smoothed and moved it about. Th ey

were almost done with this slab when

suddenly the pump began grunting.

One worker moving the concrete asked

nervously, “Do you think we should

shut the pump down?”

“Nah, it’s just a small clog,”

replied the mover. “It’ll take care of

itself. Besides, we’ve got orders not to

stop pouring!”

“I’ve heard it make a lot worse,”

added the guy holding the hose, “and

nothing happened.”

“Yeah, I know, but I can’t remember

the last time we did anything to that

pump,” replied the fi rst mover.

Just then, the pump made a menac-

ing growl. Th e metal fi tting, worn paper

thin by the abrasive concrete, couldn’t

handle the load anymore. Like a cannon

shot, the hose exploded away from the

pump. With blinding speed, it fl ew past

the man holding the end and struck the

other two workers, sending them fl ying

through the air, landing face down in

the freshly poured concrete.

By the time help arrived, it was too

late for the men.

All things wear out over time,

including industrial hose and couplings.

In many cases, you can’t see that the

hose and/or couplings are worn out

until it’s too late. If a change-out

schedule is in place, adhere to it, even

if there’s pressure to just keep moving.

If not, setting up a hose assembly

change-out schedule, whether it’s based

upon time of service or amount of

product conveyed, saves money in the

long haul and promotes a safe work-

place. All hose assemblies will come out

of service, one way or the other. You can

do it when planned and it’s convenient

for you. Or you can wait and let it take

itself out of service.

Waiting, or trying to stretch

that dollar too thin, can have devastat-

ing consequences.

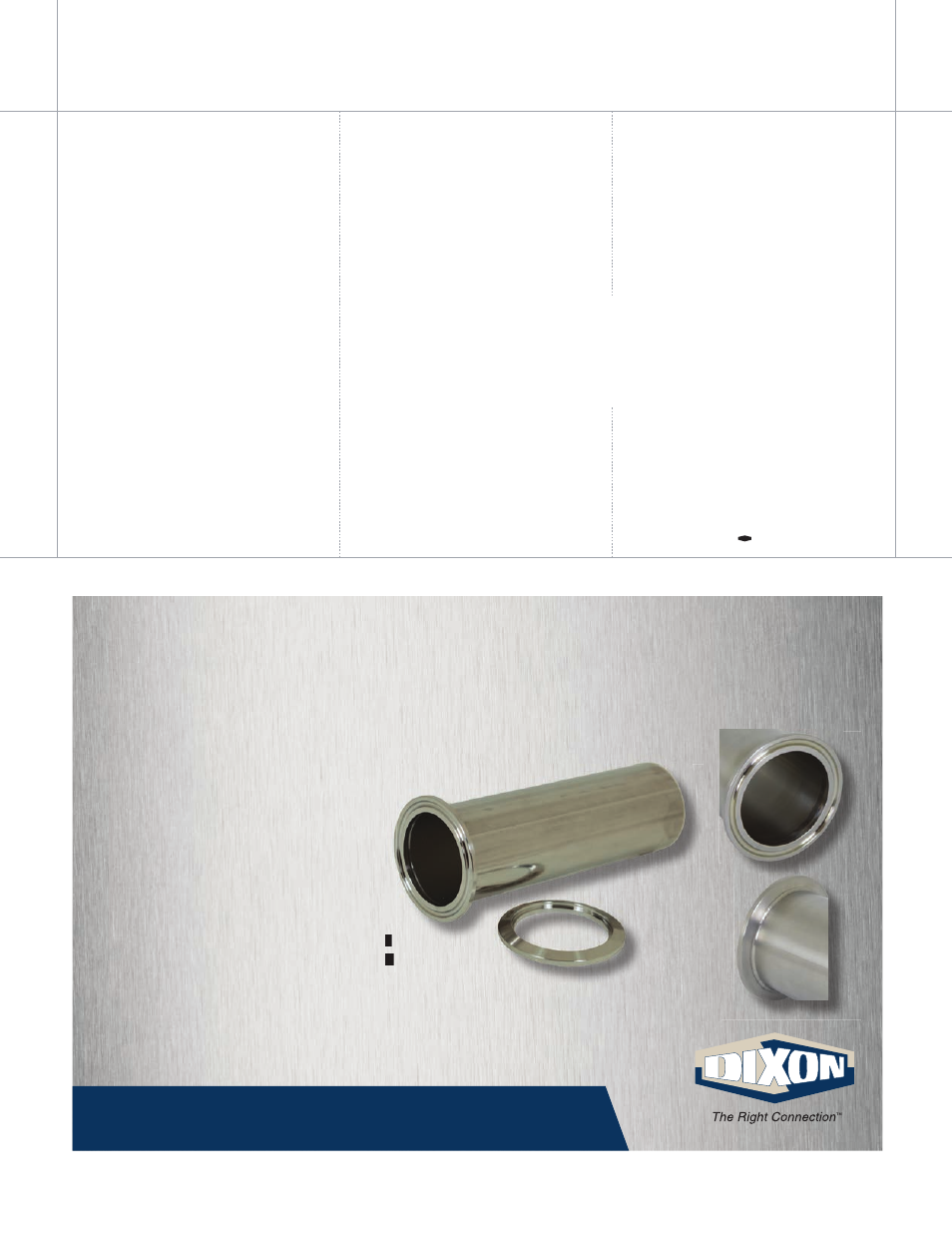

Features:

•

Just slip onto sanitary OD tube and

weld

•

No need to butt weld!

•

Size range 1" - 6"

Material:

•

304 stainless steel

All sizes are in stock at Dixon Sanitary. To

learn more about our Quick Weld Ferrules

call 800.789.1718.

dixonvalve.com • customer service: 800.789.1718

Dixon Sanitary

N25 W23040 Paul Road • Pewaukee, WI 53072 • ph 800.789.1718 • fx 800.789.4046

Dixon Sanitary Quick Weld Ferrules

An easy-to-weld assembly for non-sanitary applications.

quick weld ferrule_2013.indd 1

7/29/2013 2:24:52 PM

All things wear out over time, including industrial

hose and couplings. In many cases, you can’t see

that [they] are worn out until it’s too late.