Identifying fuel delivery systems – Mityvac MV5545 FST PRO FUEL SYSTEM TESTER User Manual

Page 16

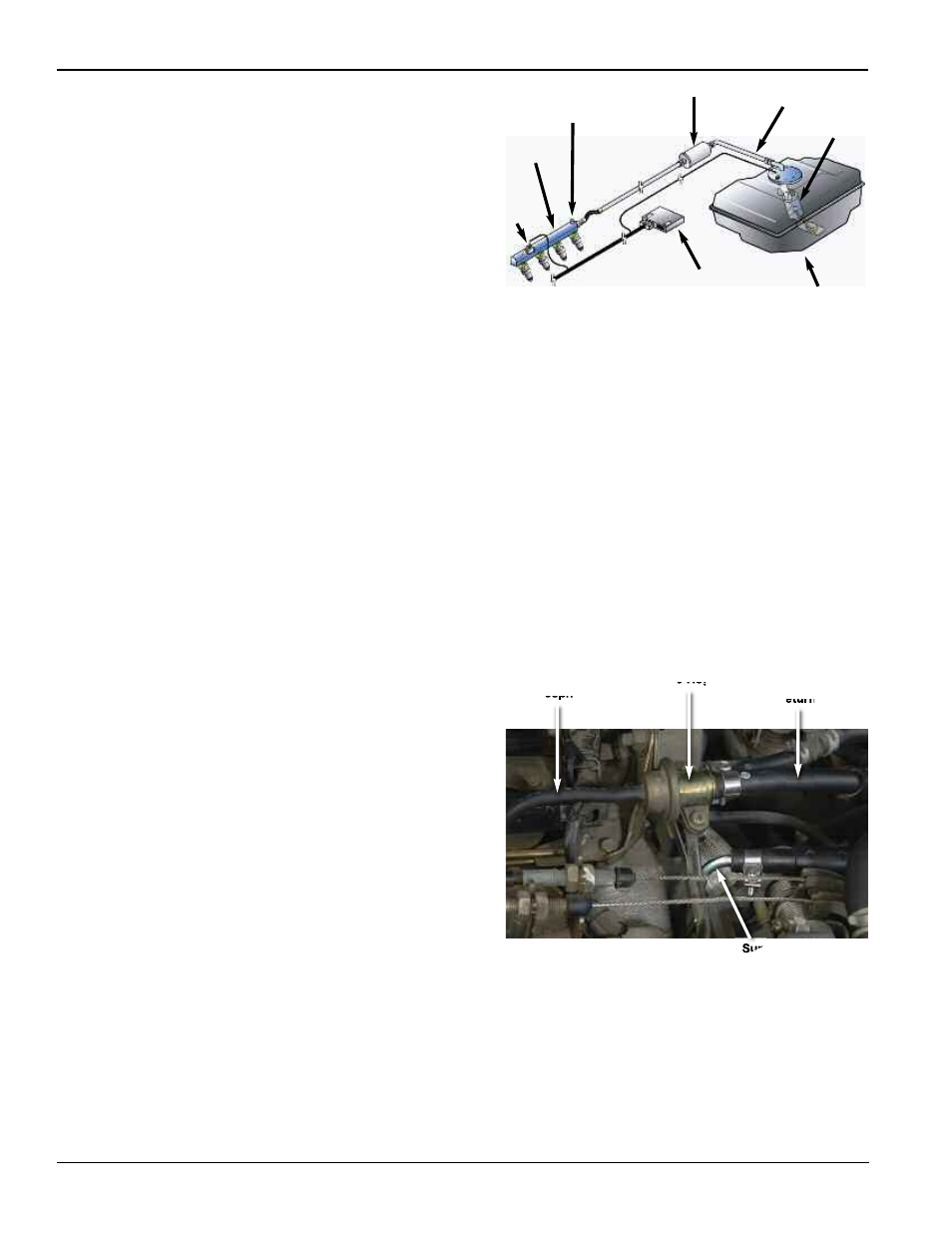

Fig. 27

Fig. 26

Page Number - 16

Form 824127

Electronically Regulated

Ford began developing an electronically regulated returnless fuel

delivery system in the late nineties, and began implementing it on

their cars in the early to mid-2000s. This system shares some of the

features and benefits of both return and returnless systems, but with

the addition of advanced control technology. The two main differ-

ences of an electronically regulated fuel system are the replacement

of the mechanical pressure regulator with an electronic pressure

sensor, and the introduction of a variable speed fuel pump (Fig. 26).

The fuel pressure sensor is mounted directly onto the fuel rail, which

ensures the most accurate reading of the pressure at the injectors.

The signal from the pressure sensor is fed to the ECM where it is

combined with other inputs such as from the O2 sensor. The ECM

processes the data and uses it to control the duty cycle of the

injectors and the speed of the fuel pump. Fuel pressure and volume

are controlled by the ECM speeding up or slowing down the fuel

pump. This eliminates the need for a pressure regulator.

Although a whole new level of technology and control has been

introduced with this system, the engine requirements are still the

same. The FST is just as effective at diagnosing an electronically

regulated system as a mechanical, and the test procedures are

just as straightforward.

Identifying Fuel Delivery Systems

Begin by opening the hood and locating the fuel rail. If the engine

has only one bank of cylinders, there will be only one fuel rail.

Engines with two cylinder banks will typically have two fuel rails,

each feeding the injectors in one of the banks. There will be a

crossover between the rails to allow fuel to flow from one side to

the other. Fuel rails vary in appearance from simple round tubes to

square or rectangular in shape.

Look for the fuel line(s). They typically come up from under the car at

the base of the firewall, run up the firewall, and then extend over to the

fuel rail(s). A return system will have two lines, one supplying fuel from

the tank, the second returning the unused fuel back to the tank. It is

easy to confuse fuel lines with lines for the evaporative system, so

inspect them closely. Fuel lines will be either steel or fuel rated rubber.

Return systems will have a pressure regulator typically mounted on

the end of the fuel rail, such that unused fuel flows out of the fuel rail,

through the pressure regulator, and into the return line. The pressure

regulator will typically have a vacuum line attached, which adjusts

fuel pressure regulation according to engine speed (Fig. 27). Some

cars will have a pulse dampener, which can be easily confused with

the regulator. The pulse damper is typically found on returnless

systems. It does not have a vacuum line attached to it, and is com-

monly mounted at the inlet, or extends from the side of the fuel rail.

Returnless fuel systems will have a single fuel line running to the fuel

rail. There will be no fuel pressure regulator located at the fuel rail.

Electronically controlled fuel systems will have a pressure transducer

mounted on the fuel rail (see Fuel System Components). The

transducer will have an obvious electrical connection with three

to five wires extending from it.

Pressure Test Port

Pressure

Sensor

Pump Module

ECM/PCM

Fuel Rail

Fuel Filter

Fuel

Tank

Fuel Supply Line

Pressure Regulator

To Manifold

Vacuum or

Atmosphere

Fuel Return Line

Fuel Supply Line