Electronic installation – Max Machinery 234 Flow Meter User Manual

Page 7

( 7 )

234-000-350 © 2005 Max Machinery, Inc.

234-000-350 © 2005 Max Machinery, Inc.

( 7 )

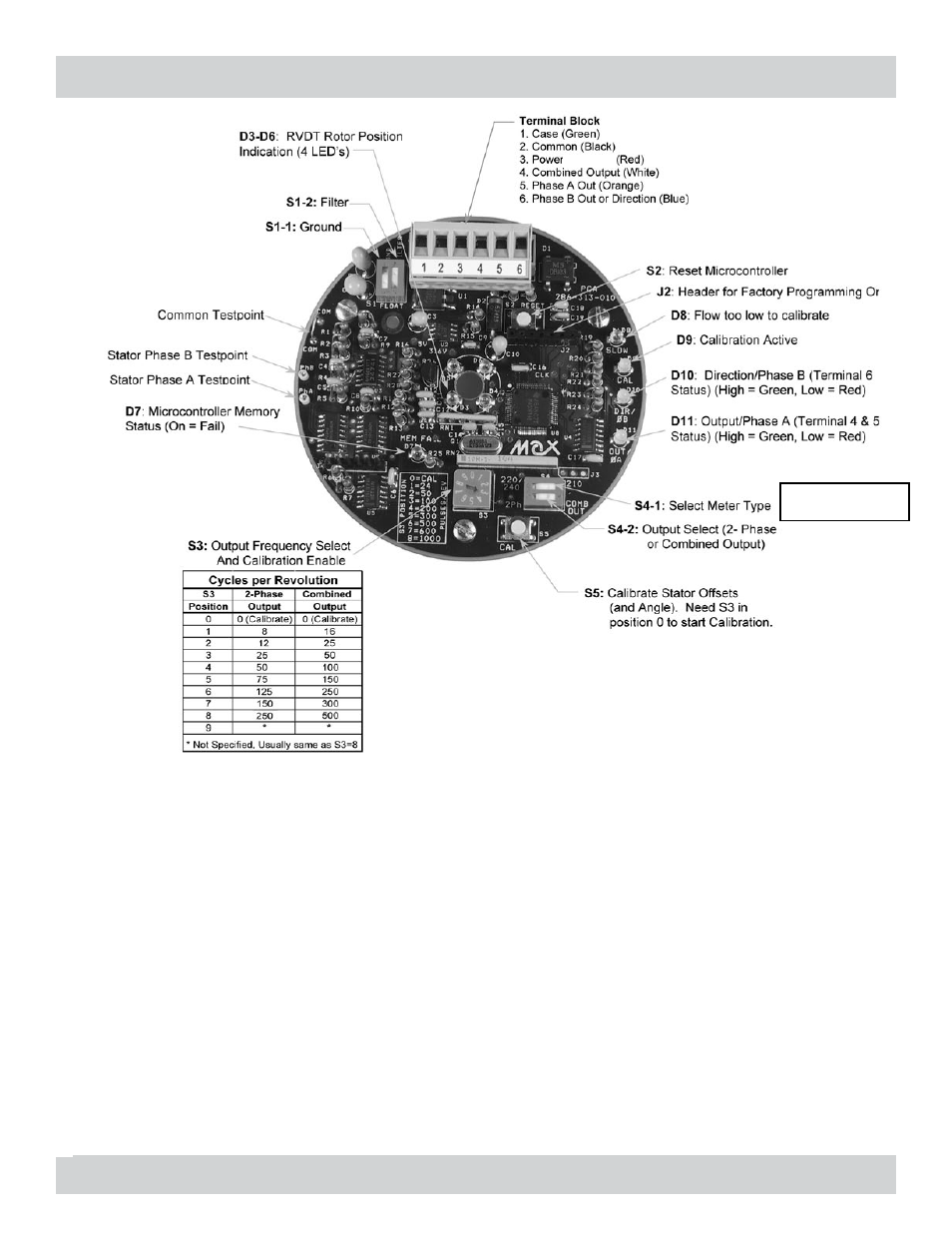

Electronic Installation

Microprocessor Reset:

S2: In the event that the tachometer does not appear to be operating correctly, resetting the microprocessor

by momentarily depressing S2 may solve the problem . While the reset button is depressed, the ‘MEM FAIL’

LED will turn on, and if the memory is good, the LED should turn back off when the button is released .

LVDT Rotor Position Indication LED’s:

D3-D6: These LED’s provide a graphical representation of the position of the LVDT slugs . This can be a

helpful troubleshooting aid when trying to determine if a meter is turning or not . The rotational pattern

observed on the LED’s corresponds directly to the speed of the LVDT slugs . At high speeds, the LED’s will just

look like they are blinking; the human eye can no longer discern the direction of motion . At very high speeds

the blinking will not even be obvious and they will all appear to be a constant brightness . At these higher

speeds, a divide-by-ten feature can be activated by pressing S5 (the ‘CAL’ button, make sure S3 is not in the 0

position, otherwise the calibration routine will be run!) . This only slows down the Rotor Position indication

LEDs, the output frequency does not change .

‘CAL’ LED:

D9: This LED changes color (red to green or green to red) 4 times per revolution while the microprocessor is

performing the calibration routine on the stator coils . When calibration is complete, it will turn off . See

Calibration Section for more information on calibration procedures

Due to the single sine wave

output of the LVDT encoder, the

resolution is 1/2 of the values

screenprinted on the PCB.

234 Series also

use 220/240

4.5-24