Maintenance – pump disassembly – Mallory Ignition Mallory COMP PUMP SERIES 250 ELECTRIC FUEL PUMP 5250_5250A User Manual

Page 4

4

www.mrgasket.com

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300FAX 216.688.8306

FORM 1038

(REV. F) 11/04

Made in U.S.A.

Printed in U.S.A.

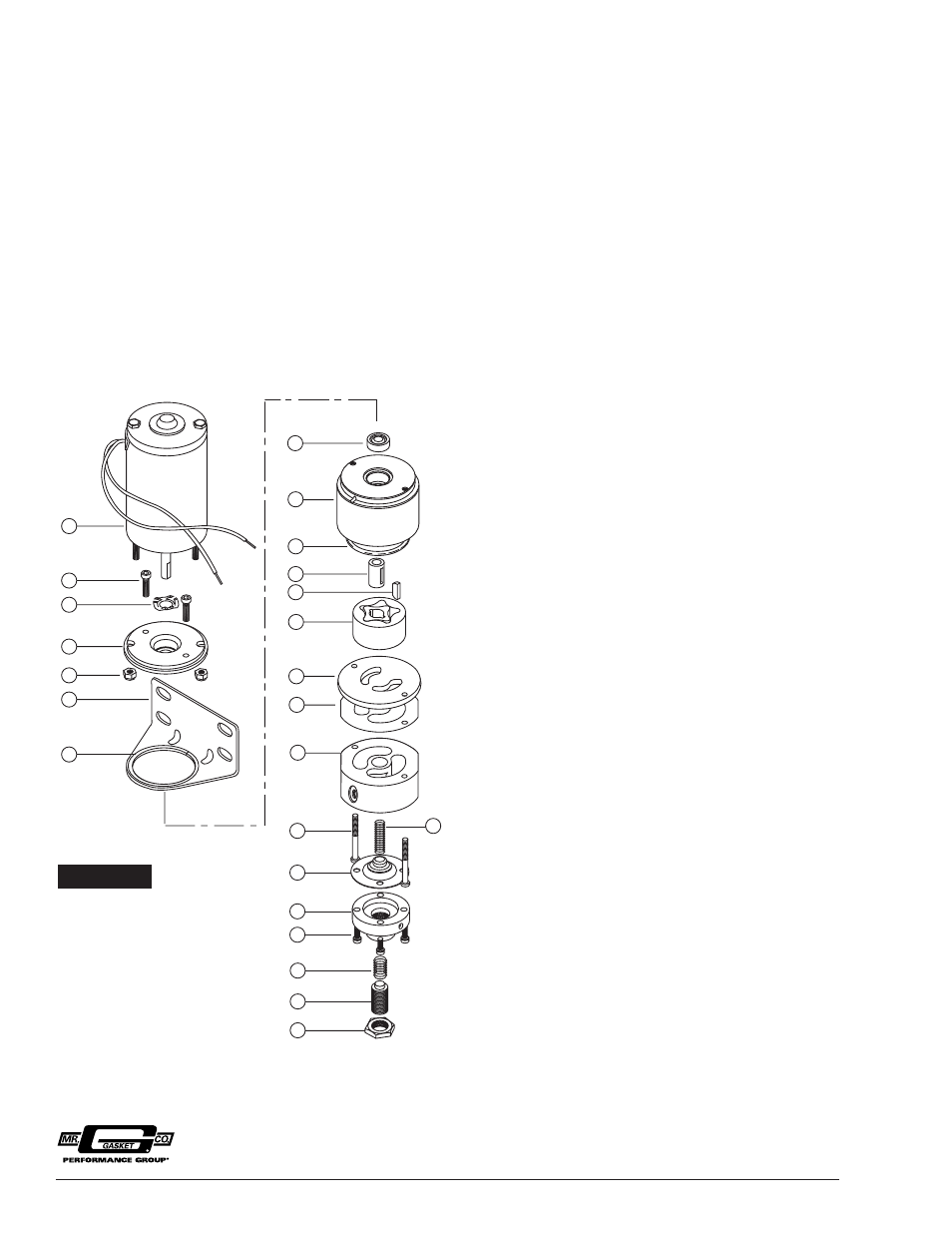

FIGURE 6

18

19

20

21

22

23

24

9

10

11

14

15

16

17

12

13

1

2

3

4

5

6

7

8

MAINTENANCE –

PUMP DISASSEMBLY

If your pump fails to produce adequate pressure or

volume, it may require cleaning. Follow the steps below to

disassemble and clean your Mallory Electric Fuel Pump.

Refer to Figure 6 while performing the following steps.

Step 1

Remove the pump from the vehicle and clean pump exterior.

Place the pump on its side on a clean work surface. Scribe

or draw a line across the pump housing, port plate and fuel

chamber so that you can reassemble the pump correctly.

Step 2

Remove the two fuel chamber screws from the bottom of the

pump. Remove fuel chamber and port plate from the pump.

NOTE: Do not drop the gerotor from the pump cavity.

Step 3

Place your hand beneath the gerotor and hold the pump in

an upright position. The gerotor should slide out of the

pump and into your hand.

Step 4

To disassemble the fuel chamber, first remove the lock nut

and adjusting screw, then turn the fuel chamber over so that

the diaphragm spring falls into your hand. Remove the four

screws holding the diaphragm cap to the fuel chamber.

Remove the diaphragm cap, diaphragm, and damper spring

from the fuel chamber.

Step 5

Clean the gerotor and reinstall it in the pump housing.

Inspect the O-ring and gasket, and replace them if

necessary. Inspect the diaphragm for any small tears or

bubbles in the surface, and replace it if necessary. Inspect

the gerotor housing and port plate for wear. If the generator

has worn through the plating, return the pump to Mallory

for repair.

Step 6

Assemble the pump in the reverse order that you

disassembled it. Test bypass pressure. Adjust bypass

so that pump is producing between 13 and 20 psi.

1. JAM NUT

2. ADJUSTING SCREW

*3. PRESSURE ADJUSTMENT SPRING

*4. CAP SCREW (4)

5. REGULATOR CAP

*6. GASOLINE DIAPHRAGM

ALCOHOL/METHANOL DIAPHRAGM

*7. FUEL CHAMBER SCREW

*8. DAMPER SPRING

9. FUEL CHAMBER

*10. FUEL CHAMBER GASKET

11. PORT PLATE

12. GEROTOR

*13. GEROTOR BUSHING KEY

*14. GEROTOR BUSHING

*15. O-RING

16. GEROTOR HOUSING

*17. SEAL

*18. BRACKET VIBRATION GASKET

19. BRACKET

20. MOTOR HOUSING NUT (2)

21. MOTOR ADAPTER

22. SPRING WASHER

23. MOTOR ADAPTER SCREW (2)

24. MOTOR

*THESE PARTS ARE INCLUDED IN SEAL / DIAPHRAGM KITS

PART NO. 3171 FOR GASOLINE

PART NO. 3172 FOR ALCOHOL

IMPORTANT: Turn fuel chamber screws by hand until they

contact the chamber. Then torque to 24 inch/pounds