Mallory Ignition Mallory DISTRIBUTOR А557 User Manual

Mallory distributor model #a557, Installation instructions, Installation

MALLORY IGNITION

www.mallory-ignition.com

1

Mallory Distributor Model #A557

FORM 1627

INSTALLATION INSTRUCTIONS

OVERVIEW

Mallory distributor Model A557 is intended for use with 1936-1969 Harley-

Davidson® Big Twin motorcycle engines. The Mallory A557 replaces the

original equipment (OE) points type distributor. The unit can be installed

without engine disassembly when stock cylinders and heads are used.

The Mallory A557 offers adjustable advance, adjustable RPM limit settings

in 100 RPM increments, and switch selectable single or dual fire modes.

Single fire mode improves starting, reduces the occurrence of backfiring at

low RPM, and improves power at high RPM. A red status LED flashes when

the engine reaches top dead center (TDC) and allows easy static timing.

The status LED also provides diagnostic information. A green VOES LED

illuminates when the VOES (vacuum switch) input is active.

AVOIDING HEAT RELATED FAILURES

Heat kills electronics. The Mallory A557 uses electronic devices rated for

operation at 105 deg. C (221 deg. F), the highest rating available. The unit

can tolerate somewhat higher temperatures, but exposure to temperatures

above 125 deg. C (257 deg. F) will greatly reduce life expectancy. We

sometimes see problematic applications where several module failures

have occurred. The failure mode is a classic thermal intermittent where the

module stops firing one cylinder when it gets hot. We have found that these

problematic applications share one or more of the following characteristics:

• VOES switch removed or non-functional. All street driven engines require

vacuum advance. Without vacuum advance at idle and part throttle,

thermodynamic efficiency is reduced and engine temperatures increase

significantly.

• Improper carburetor jetting resulting in lean air/fuel ratio (AFR). A lean

AFR will cause the engine to run very hot. All performance engine modi-

fications necessitate carburetor re-jetting. Carburetors are never cor-

rectly jetted out-of-the-box. The only practical means of correctly jetting

a carburetor is to test the motorcycle on a chassis dyno equipped with an

exhaust gas sniffer.

• Lack of an oil cooler on a 95 CID or larger engine.

• Exhaust pipe without heat shield in close proximity to the distributor.

• If any of the above applies to your application, the Mallory A557 may be

exposed to excessive temperatures resulting in reduced life expectancy.

Use an infrared thermometer to check the module temperature.

INCLUDED AND ADDITIONAL REQUIRED PARTS

All units include a parts bag with crimp terminals for coil and VOES hookup.

• Electrical System - A 12 volt electrical system is required. Check that the

charging system is properly regulated and not producing over 16 volts.

• Spark plugs – Resistor spark plugs must be used in place of the non-

resistor spark plugs that were original equipment.

• Ignition wire - Spiral core or carbon core wire must be used in place of the

solid core or copper core wire that was original equipment. We recom-

mend the ACCEL 300+ Race Wire.

• Coil(s) – A coil or coils with a total primary resistance of 2-4 ohms is

required. The stock 5 ohm coil is not compatible. For single fire we recom-

mend the ACCEL 140408 coil. For dual fire use ACCEL part number 140407.

• Distributor clamp – A 1966-69 style distributor clamp (original or aftermar-

ket) is required.

CAUTION: CAREFULLY READ INSTRUCTIONS BEFORE PROCEEDING. NOT LEGAL FOR USE OR SALE ON POLLUTION CONTROLLED VECHICLES

INSTALLATION

1. Turn off the ignition switch and disconnect the battery ground

cable before proceeding.

2. Rotate the engine until it is on the compression stroke on the

front cylinder. Continue to rotate the engine until the TDC

mark is visible through the timing hole. (see pg 7)

3. Remove the existing distributor if still in the engine.

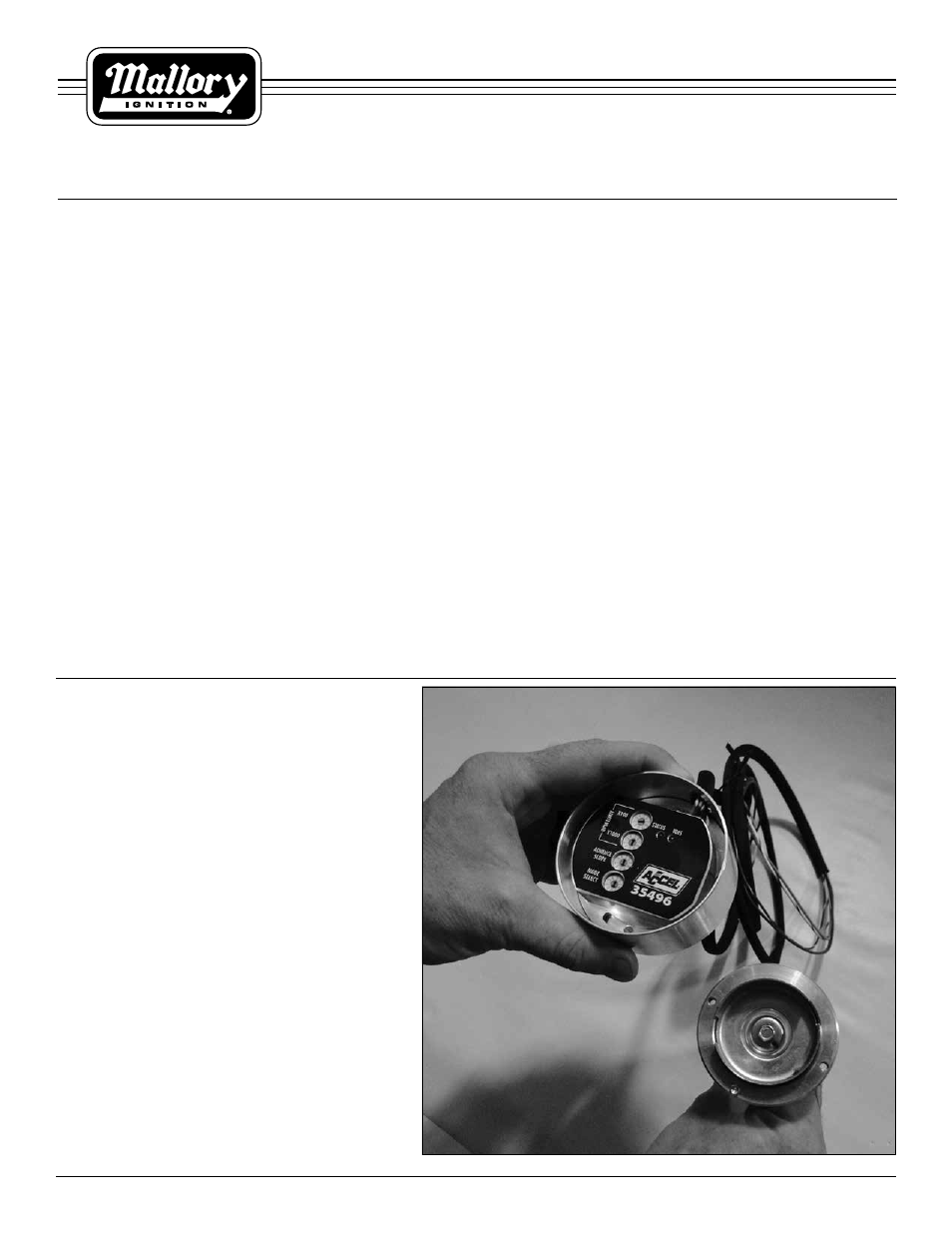

4. Remove the two hex-head screws and the top cover from the

new Mallory A557 distributor. Remove the two hex standoffs

and remove the module and upper housing from the distribu-

tor base assembly. (Figure 1)

5. Install the distributor base assembly in the engine with the

screw holes and shutter wheel positioned as shown in figure

2. It may be necessary to pull the distributor out, turn the

shaft, and reinstall to get the shutter wheel at the approxi-

mate angle shown. The shutter wheel openings should be at

about the 11 o’clock and 7 o’clock positions. The screw holes

should be at the 9 o’clock and 3 o’clock positions.

6. Install the distributor clamp and snug the clamp bolt loosely

so that the distributor can still be rotated.

7. Reinstall the upper housing and module assembly onto the

distributor base assembly as shown in figure 1. Note: the

upper housing will only install one way due to the locating

screw. Rotate the base assembly slightly if necessary so that

the opening in the shutter wheel lines up with the slot in the

upper housing (figure 3).

8. Reinstall the two hex standoffs through the module and upper

housing and into the distributor base assembly. We recom-

mend using a drop of blue threadlock to prevent the standoffs

from vibrating loose. Tighten the distributor clamp.

9. Set rotary switches according to the separate “Operating Figure 1