Magnum Venus Plastech Pro Series Mini Pro Gel Coater User Manual

Page 26

Mini Pro Gel Coater Operations Manual

Rev. 09/2012

Page | 26

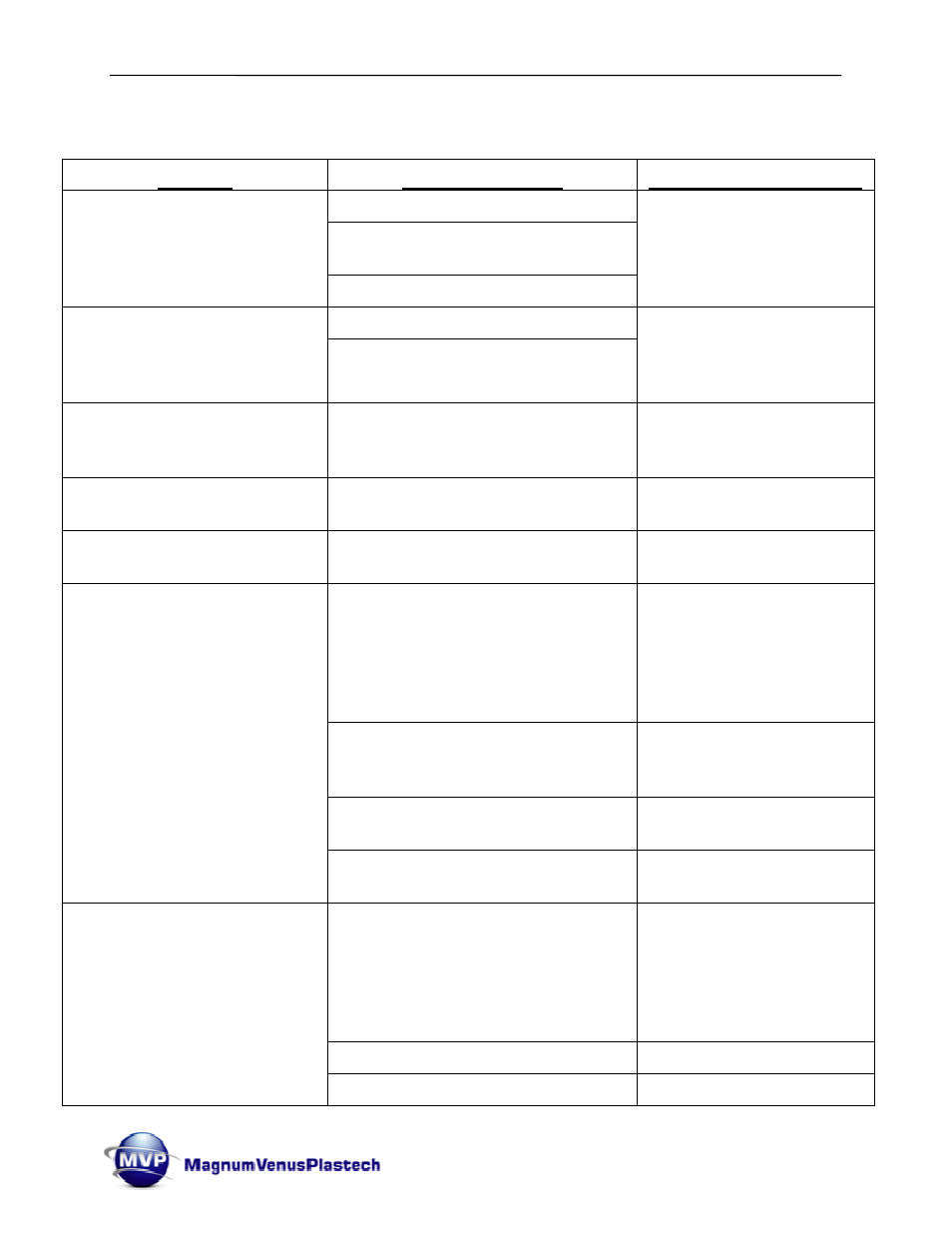

Basic Troubleshooting for AT Guns:

Problem

Possible Cause(s)

Recommended Solution

Air leaking from exhaust

port on back handle while

trigger is OFF position.

O-ring material worn or cut.

Replace O-rings.

O-rings on catalyst piston worn or

cut.

O-rings on trigger valve worn or cut.

Air leaking from exhaust

port on back of handle

while trigger in OFF or ON

position.

O-rings on trigger valve worn or cut.

Replace O-rings.

O-rings on catalyst valve and/or

material piston worn or nicked.

Catalyst leaking from

catalyst tip while gun is

sitting, not being triggered.

O-rings on catalyst valve worn or

cut.

Replace O-rings.

Catalyst leaks from week

hole on catalyst side of gun.

O-rings on catalyst valve worn or

cut.

Replace O-rings.

Catalyst leaks from week

hole on catalyst side of gun.

O-rings on catalyst valve worn or

cut.

Replace O-rings.

No catalyst is coming from

gun.

Catalyst air piston is not actuating.

Check for clogged catalyst

air passages (small holes

underneath back cylinder).

Note: There is more than

one passageway from

holes.

Plugged catalyst restrictor (allen

screw with orifice located in front of

catalyst valve).

Clean and clear orifice in

front of catalyst valve.

Plugged catalyst passageway in

head of gun or catalyst tips.

Inspect, clean and clear

passageways.

No catalyst flow to gun.

See “Slave Pump-Trouble

Shooting”

Material is leaking from tip

(front of gun).

Loose diffuser seat.

Tighten diffuser seat 1/4 to

1/2 turn at a time until snug

and then one more 1/4

turn. Over tightening of

diffuser seat may cause

bindng of material needle.

Worn needle and/or seat.

Replace worn items.

O-ring on diffuser nicked or cut.

Replace O-rings.