Magnum Venus Plastech Pro Series Mini Pro Gel Coater User Manual

Page 25

Mini Pro Gel Coater Operations Manual

Rev. 09/2012

Page | 25

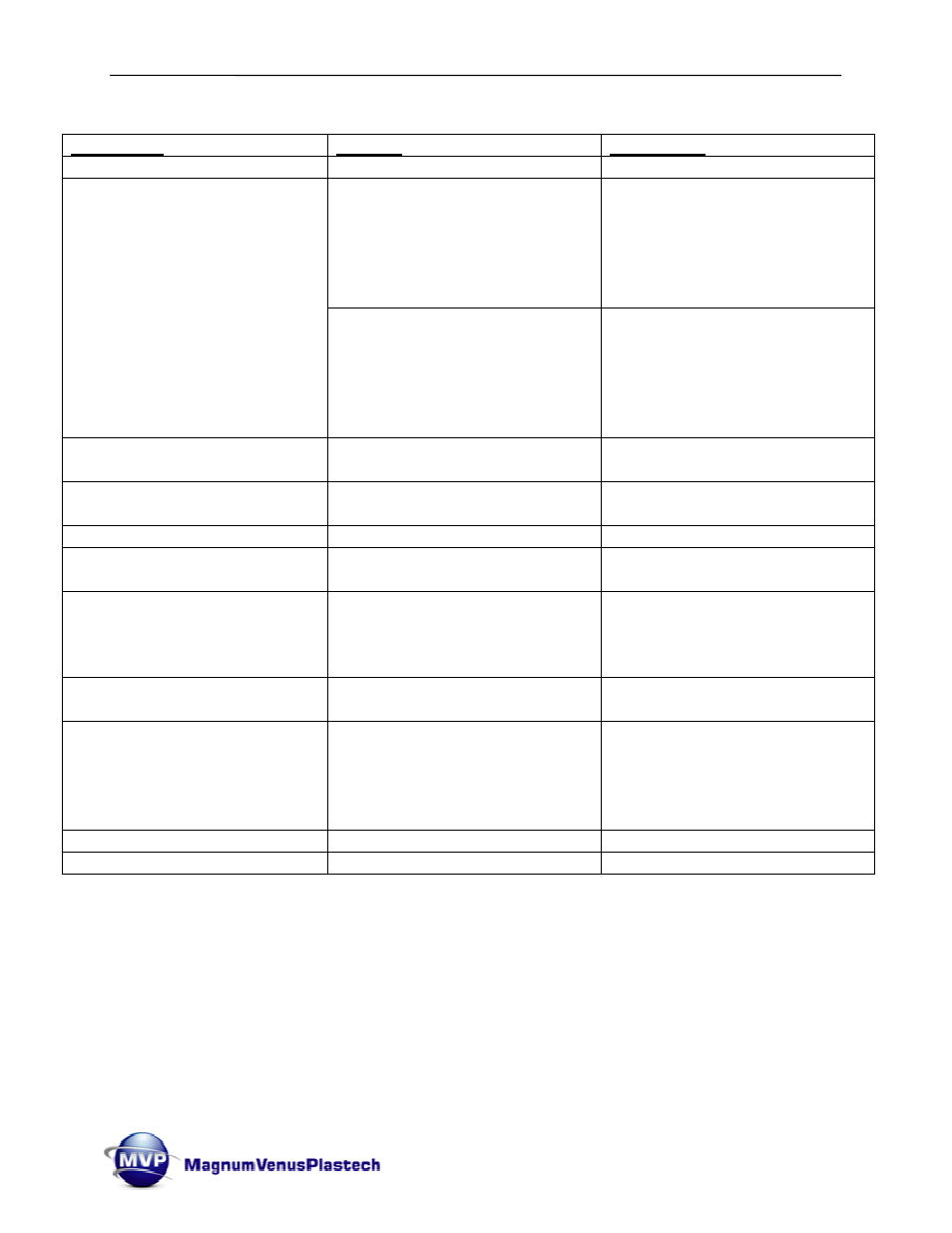

PROBLEM

CAUSE

SOLUTION

Fitting or nipple damaged.

Danger: To prevent injury,

always relieve fluid pressure

before attempting to remove

components.

Replace damaged parts.

Crimped hose.

Danger: To prevent injury,

always relieve fluid pressure

before attempting to remove

components.

If the hose has been sharply

bent, the plastic liner may be

ruptured. Remove and

replace hose.

Slow Cure on one side of

the fan.

Turbulent Mixer partly clogged

or damaged.

Clean or replace the Turbulent

Mixer.

Distribution Ring partly

clogged.

Remove the mix chamber and

clean the distribution ring.

Mix Housing damaged

Replace as needed.

Fingers – heavy lines in the

spray fan.

Gel Coat too cold

Increase gel coat temperature.

Use Inline resin heater.

Pump air pressure too low

Slowly increase the pump

pressure in 5psi (1/2 bar)

increments and check spray

fan.

Air- Assist pressure is too low

Slowly Increase Air- Assist

pressure as needed.

Pump has short travel –

stuttering near top or

bottom of stroke

Valve block is not shifting all

the way or shifting before

completing a full stroke.

Check air supply to shift block

it should be 90 -100psi (6 –

7bar). Replace Actuator Valve

(MPM-2589) or Valve (VPRO-

2003) as needed.