Magnum Venus Plastech Pro Series Mini Pro Gel Coater User Manual

Page 23

Mini Pro Gel Coater Operations Manual

Rev. 09/2012

Page | 23

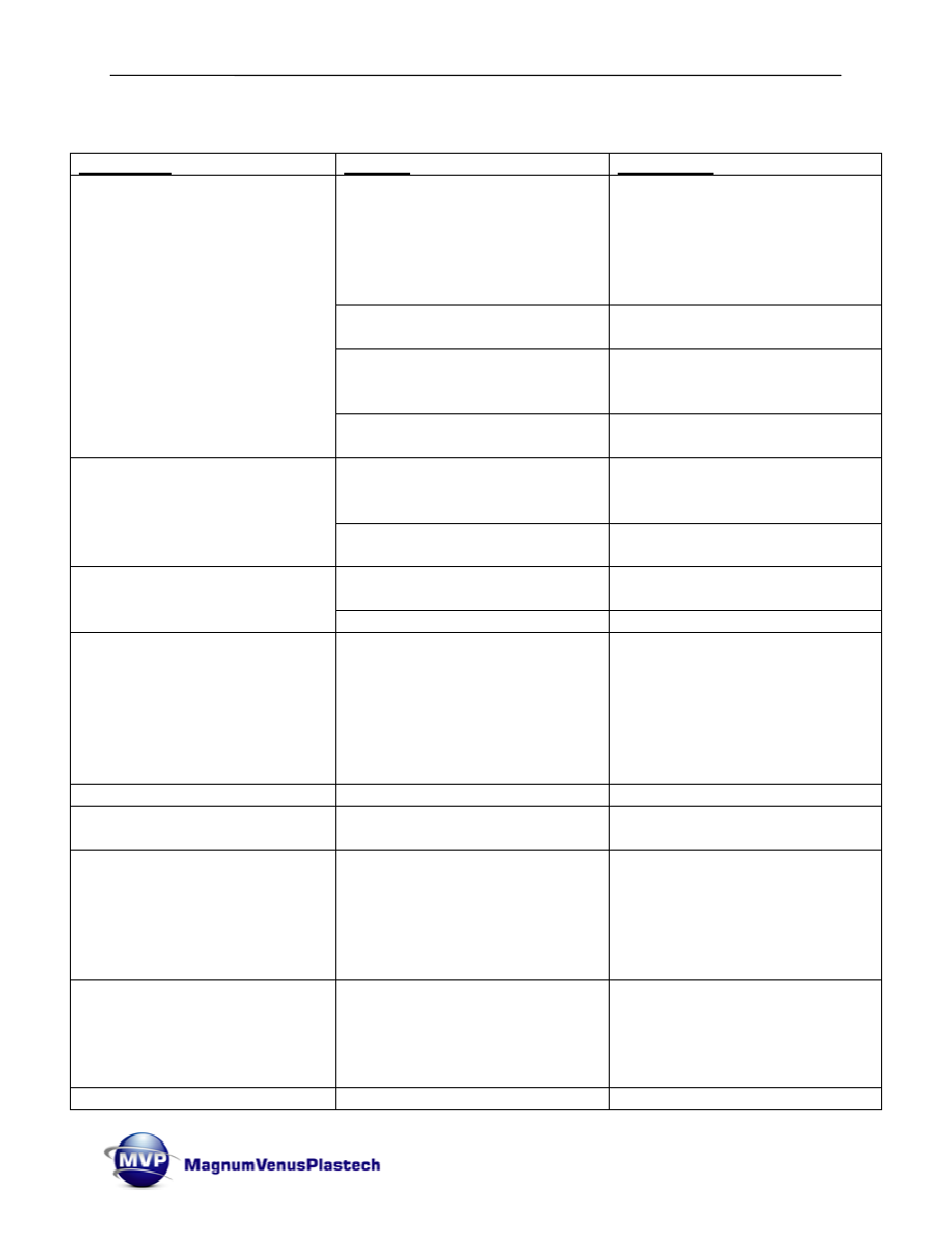

PROBLEM

CAUSE

SOLUTION

Resin hose plugged.

Danger: To prevent injury,

always relieve fluid pressure

before attempting to remove

components.

Flush hose with solvent. If

material is hard, replace hose.

Pick-up wand assembly

leaking.

Tighten assembly fittings.

Resin filter clogged.

Disassemble and clean the

resin filter. See Chapter 7:

Accumulator & Filter.

Material too cold or air

pressure low.

Heat material or increase

pump pressure.

Narrow Fan

Material too cold, nozzle too

large or air pressure low.

Heat Material, use smaller

nozzle, or as a last resort

increase pump pressure.

Resin filter clogged.

Disassemble and clean the

resin filter.

Wide Fan

Air pressure too high.

Lower pressure then increase

pressure to the desired fan.

Nozzle too small or too wide.

Change nozzle.

Round fan

Orifice in nozzle worn,

clogged, or damaged.

Push fine wire through orifice

from back side. Use

fingernail to clean material

form “V” shaped notch in front.

Soak hardened material in

solvent. If notch is rough or

worn, replace nozzle.

Air-assist pressure too high.

Decrease air-assist pressure.

Excessive Misting

Air pressure too high.

Reduce air pressure to gel

coat pump.

Heavy pulsation

Resin accumulator plugged.

Danger: To prevent injury,

always relieve fluid pressure

before attempting to remove

components.

Disassemble accumulator and

clean.

Pump jumps on upstroke

Piston ball worn or not seating

properly.

Replace piston ball and piston

cups. Be sure to lubricate ball

and cups thoroughly with Red

Grease. See Chapter 6: Pro

Pump.