Magnum Venus Plastech Pro Series Mini Pro Gel Coater User Manual

Page 22

Mini Pro Gel Coater Operations Manual

Rev. 09/2012

Page | 22

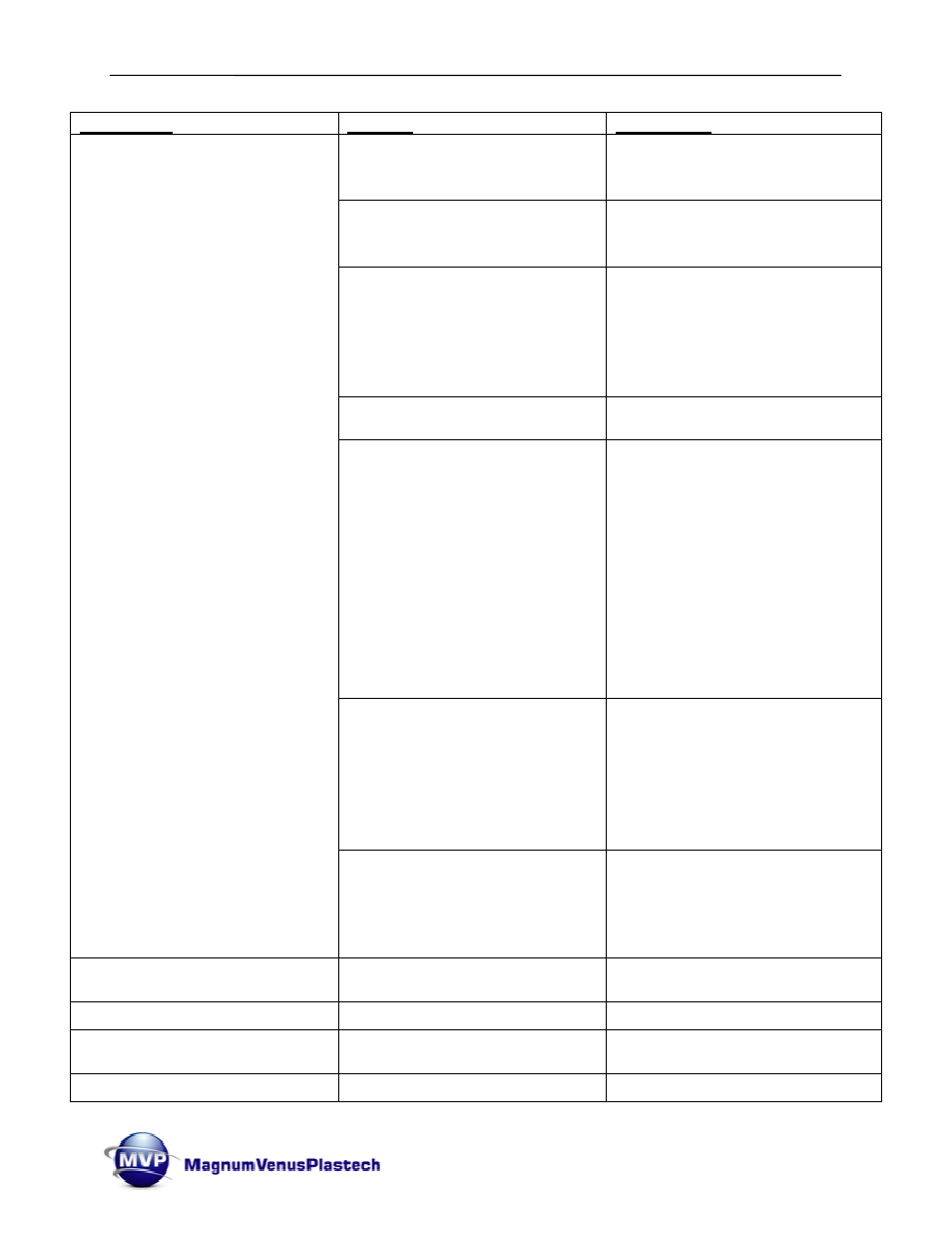

PROBLEM

CAUSE

SOLUTION

Air lock in catalyst pump.

Remove air lock. See

Appendix: Air Lock in the

Catalyst Pump.

Catalyst pump piston seal

worn or damaged

Replace piston seal. During

reassembly, be sure spring in

seal faces top of pump

Catalyst pump outlet body

damaged.

Replace catalyst pump outlet

body and piston seal. During

reassembly, be sure spring in

seal faces top of pump.

Prevent by connecting catalyst

pump vertically.

Catalyst pump check valve

blocked or stuck.

Disassemble check valve and

remove blockage.

Catalyst hose plugged.

Danger: In the next steps

you will be dealing with

fluids under high pressure.

Catalyst will be sprayed

from the hose fitting when

the fitting is loosened.

Follow safety instructions

read the Safety & Warning

section in the beginning of

this manual.

Relieve pressure from the

system. Replace the catalyst

hose with new one.

Resin or gel coat too cold.

Consult your materials supplier

for proper temperature.

Maintain a draft-free

environment of about 70

degrees F. An auxiliary heat

source may be required to

reduce gel time.

Piston cups, piston ball, or

pump cylinder worn.

Inspect the piston cups, piston

ball, and pump cylinder. Clean

and replace any damaged

components. See Chapter 6:

Pro Pump.

Low output on upstroke of

Pro pump

Screen of pump pick-up wand

blocked.

Unscrew screen from hose and

clean.

No fan, constant low output,

or fast cure

Resin filter blocked.

Disassemble and clean filter

body and screen, with solvent