Magnum Venus Plastech Flex Molding Process PPVS - VACUUM SENSOR User Manual

Page 22

PPVS (Red) Vacuum Sensor Manual

Rev. 03/2013

Page | 22

Testing using the in box leak circuit:

1. Connect the PPVS supply signal to the Inject port

on the control box.

2. Connect one of leak circuit lead signal to the top

of the PPVS (6mm push fit) using the tube and

6mm-4mm reducer provided.

3. Then connect the other leak signal to the

indicator.

4. Adjust the PPVS, when the indicator is on – the

machine would be running. See image below.

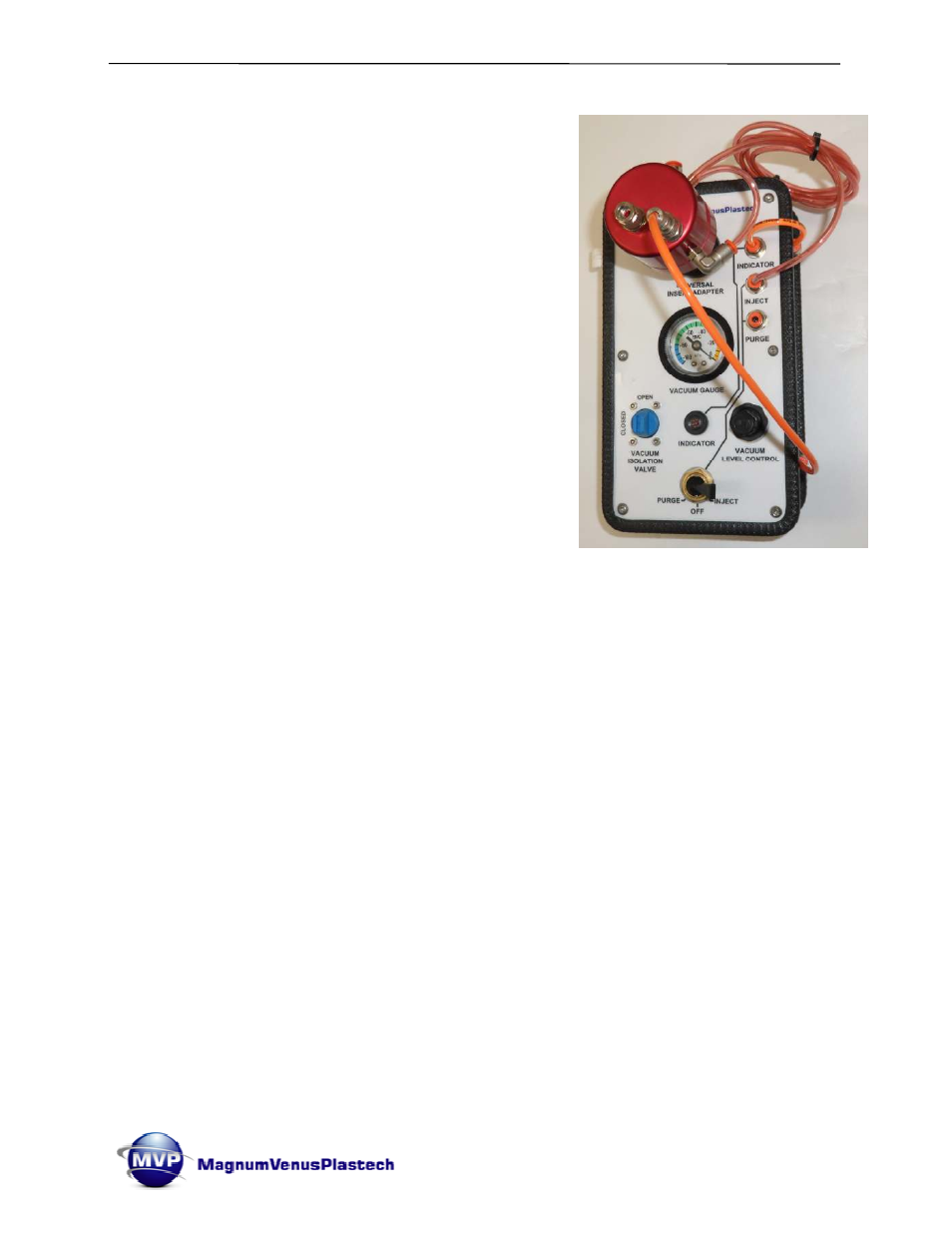

Testing PPVS for vacuum leak:

1. Load the PPVS valve into the Universal Insert Adaptor port.

2. Connect the INJECT Output on the control box to the PPVS supply port using 4mm

tube.

3. Connect the PPVS signal line to the pneumatic Indicator on the control box.

4. Using the Vacuum Level Control adjust the vacuum to the desired level.

5. Turn the Vacuum Isolator valve to the Closed position (horizontal) to lock the

vacuum level – if the vacuum level moves (leaks) down the seal in the valve is not

holding vacuum.

Blind Adjustment:

The term “Blind adjustment” means that adjustment can be made without any reference

to the actual switching point of the PPVS-Infusion. In other words the user simply turns

the adjusting screw anticlockwise by a certain number of turns to make the PPVS more

sensitive (higher vacuum level) and clockwise less sensitive (lower vacuum level –

closer to zero).