Adjusting the ppvs – Magnum Venus Plastech Flex Molding Process PPVS - VACUUM SENSOR User Manual

Page 21

PPVS (Red) Vacuum Sensor Manual

Rev. 03/2013

Page | 21

Connects into the MPG leak signal.

Adjusting the PPVS:

Testing and Adjusting using the Calibration Box:

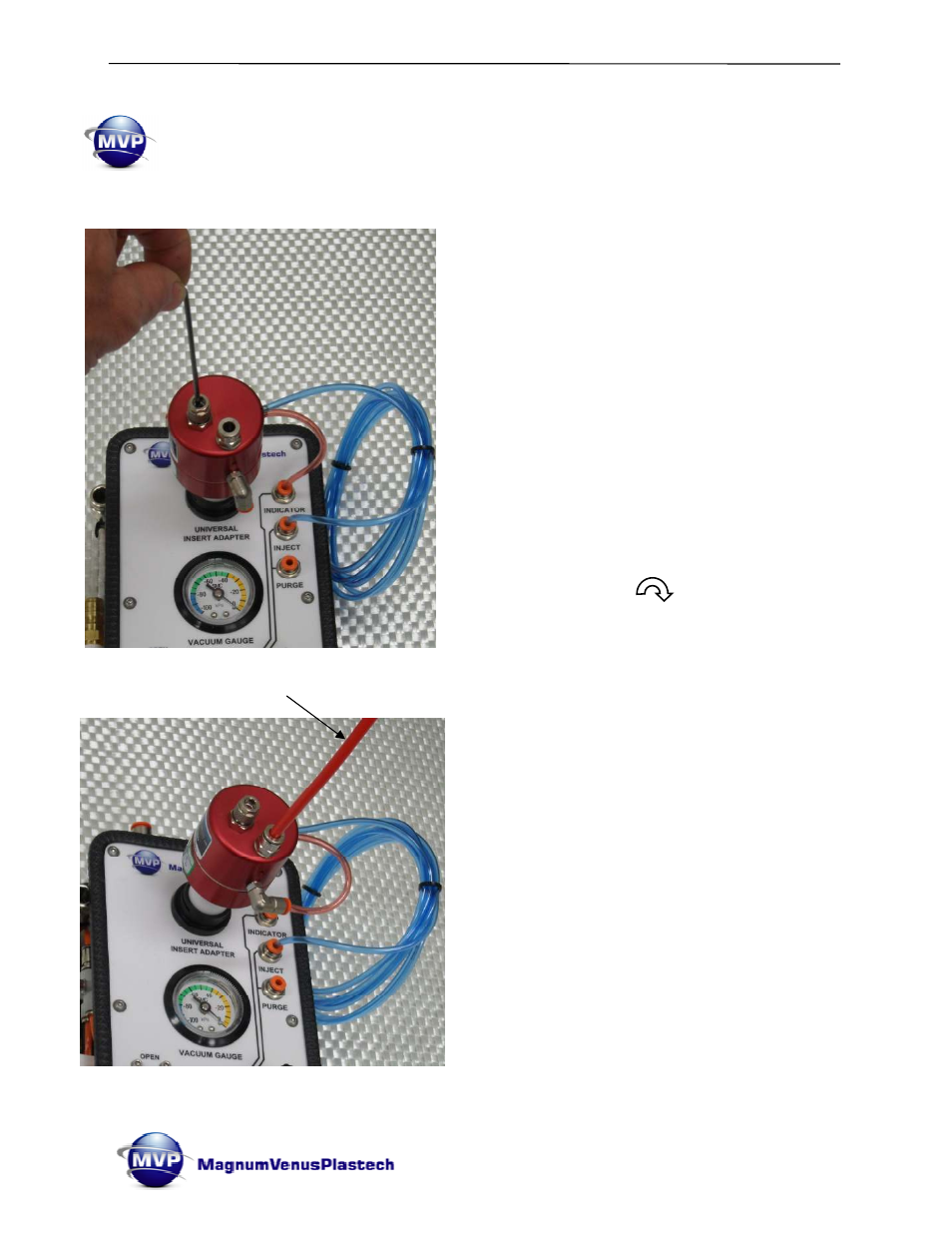

1. Option #1 - connect the INJECT Output

on the control box to the PPVS supply

port using 4 mm tube.

2. Connect the PPVS signal line to the

pneumatic Indicator on the control box.

3. Using the Vacuum Level Control adjust the

vacuum level Up/Down to determine the

vacuum pressure that the valve activates &

deactivates at. The indicator will signal red

when the valve is active.

4. To Adjust/Change the vacuum pressure at

which the valve activates use the 2.5 mm

Allen Key provided. Turn the adjustment

screw Clockwise to switch closer to

atmosphere (nearer to zero) and

Anticlockwise to switch down to -300mb

(higher vacuum pressure).

Option #2 – Test with Unit connected – for

SSB or Innovator units the 4mm pipe may be

left connected as designed and a 6mm pipe

connected between the Leak Signal on top of

the PPVS and the machine’s MPG. The

machine can then be put on re-circulation and

observed to stop when the PPVS signals at

the chosen switch point.

1. Connect the INJECT Output to the PPVS

supply port using 4 mm tube.

2. Then “Tee” the PPVS Leak Signal port

on the top of the PPVS into the MPG

signal using 4 or 6 mm tube.

3. Using the Vacuum Level Control adjust

the vacuum pressure Up/Down. The Unit will stop when the PPVS activates the leak port.