Magnum Venus Plastech Flex Molding Process IVx3 MODULE 8018 User Manual

Page 21

Vacuum Valve Service Module Manual

Rev. 10/2012

Page | 21

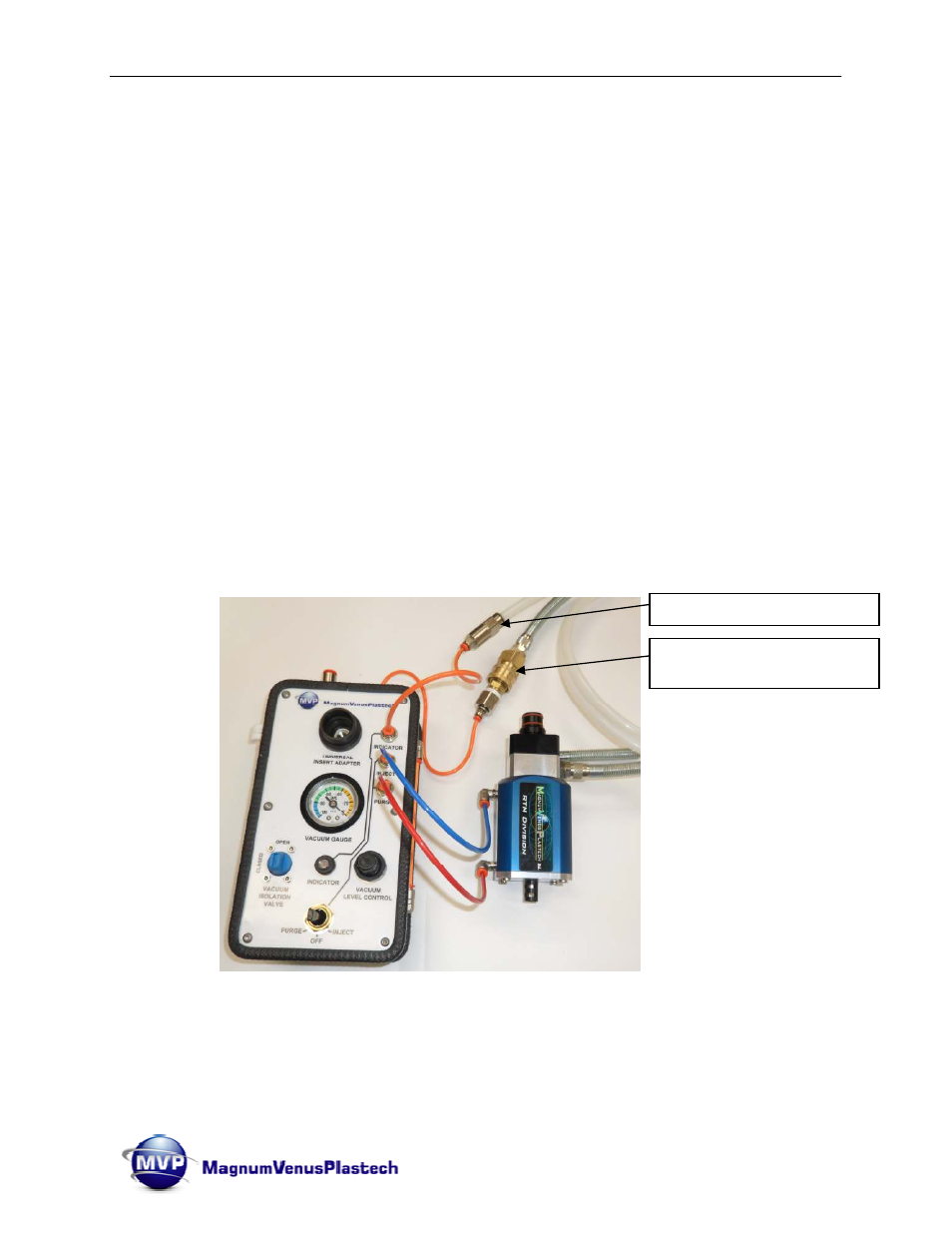

IVx3 Purge Outlet to Indicator

IVx3 Resin Inlet to Optional

air source.

Fluid Section Testing – Pressure:

WARNING: During pressure testing, ensure the IVX3’s resin injection port is

directed away from yourself and others. Some of the tests will vent air through this

port.

1. Place the IVX3 on a bench; ensure the injection port is not connected (for example

into the universal insert on the top of the IVX3 Service Module).

2. Connect the Inject output on the top of the Service Module to the Inject signal port

on the IVX3.

3. Connect the Purge output on the top of the Service Module to the Purge signal port

on the IVX3.

4. Ensure the IVX3 is in the closed position.

5. Connect the IVX3 Purge Outlet to the indicator on the Service Module or a pressure

gauge.

6. Connect the IVX3 Resin Inlet to the pressure output on the Service Module (6–7 bar

/ 87-100 PSI) and check the indicator/gauge. (See image below)

7. If pressure is seen at indicator/gauge, the valve is leaking between the resin Inlet

and Purge outlet.

8. Apply soapy water to the seal in the Lower Valve Body (6986) and look for bubbling

that would imply a leak (do not point the resin outlet directly at yourself). It is

acceptable to have a small leak here.