Calibration – Alto-Shaam ECOSMART HFT2SYS-400 User Manual

Page 23

HFT2 INSTALLATION/OPERATION/SERVICE MANUAL • 21 .

s e R V i C e

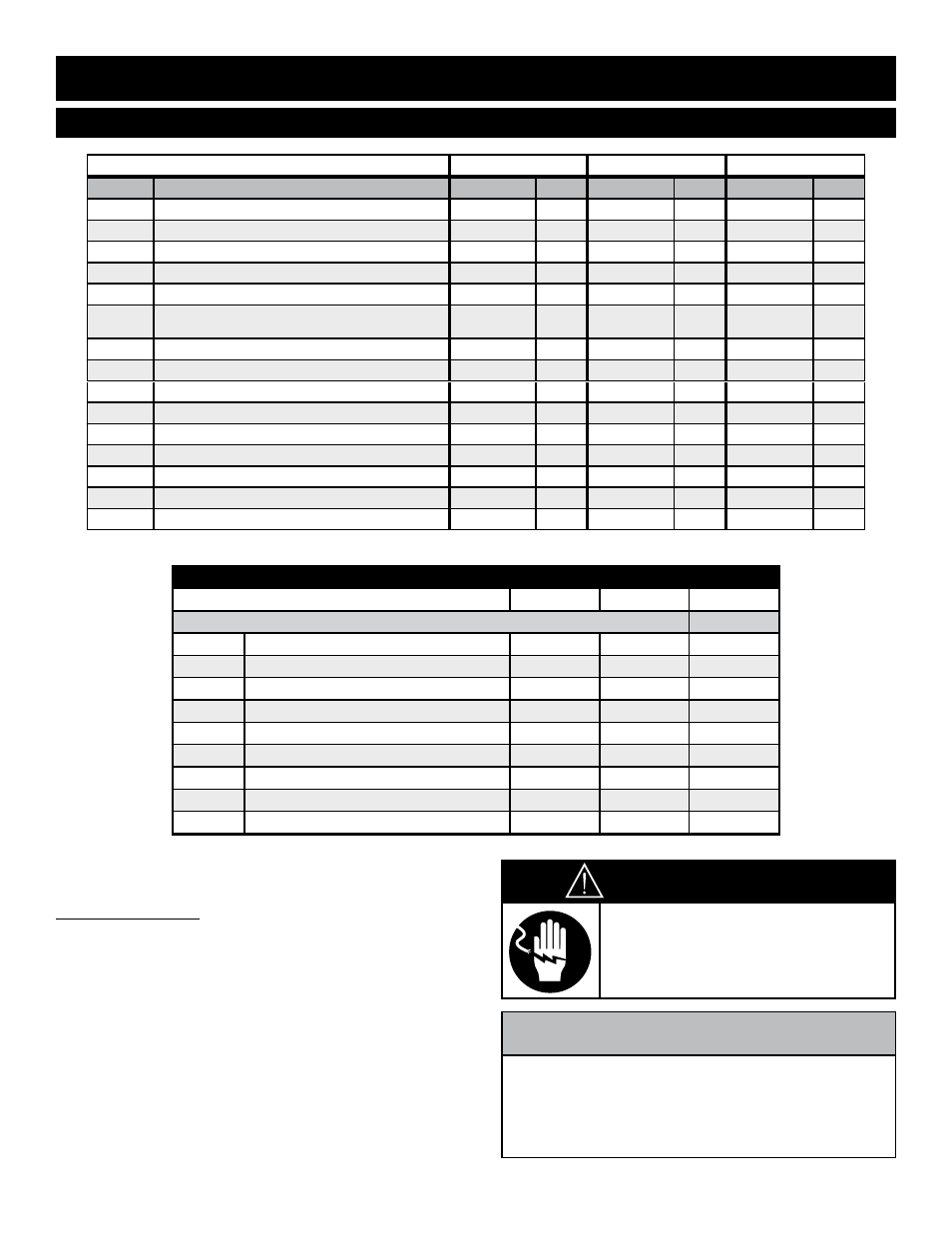

s e R V i C e P A R t s L i s t - B A s e

mODeL >

HFt2-300

HFt2-400

HFt2-500

item

DesCRiPtiON

PARt NO.

qty

PARt NO.

qty

PARt NO.

qty

1

CORD COVER PLATE

1006591

2

1006591

2

1006591

2

2

BASE STAnD TOP PAnEL

1006995

1

1012228

1

1008348

1

3

BASE SUPPORT SPOT

5005235

1

5013540

1

5007460

1

4

BASE STIFFEnER, SPOT

5013483

2

5013541

2

5012923

2

5

T-BLOCK

BK-3019

1

BK-3019

1

BK-3019

1

6*

CORDSET 208-240V

230V

CD-33840

CD-3922

1

1

CD-3588

CD-3922

1

1

CD-3588

CD-3922

1

1

7

CASTER, RIGID 5" (127mm)

CS-2025

2

CS-2025

2

CS-2025

2

8

CASTER, SWIVEL 5" (127mm) WITH BRAKE

CS-2026

2

CS-2026

2

CS-2026

2

9

PLUG, 7/8" HOLE

PG-3559

1

PG-3559

1

PG-3559

1

10

RIVET, BLInD, #44, STnLS

RI-2100

72

RI-2100

64

RI-2100

72

11*

3/8-16 x 1-1/2" HEx CAP

SC-22553

6

SC-22553

6

SC-22553

6

12

5/16-18 x 5/8" SERR . HEx HD SCREW

SC-2351

16

SC-2351

16

SC-2351

16

13

6-32 x 1-1/4" ROUnD HD

SC-2365

2

SC-2365

2

SC-2365

2

14

8-32 x 1/2" PHIL SCREW

SC-2425

8

SC-2425

8

SC-2425

8

15*

3/8" ID 7/8" OD S/S FLAT WASHER

WS-23991

6

WS-23991

6

WS-23991

6

*nOT SHOWn

D A N G e R

enSURe pOWeR SOURCe

matCHeS vOltage Stamped

On applianCe nameplate.

C A u t i O N

tHiS SeCtiOn iS pROvided FOR tHe aSSiStanCe

OF QUaliFied SeRviCe teCHniCianS OnlY and

iS nOt intended FOR USe bY UntRained OR

UnaUtHORiZed SeRviCe peRSOnnel.

Cable Heating ReplaCement SeRviCe KitS

HFt2-300

HFt2-400

HFt2-500

Kit nUmbeR >

4880

4881

5

4880

SeRviCe Kit inClUdeS:

CB-3045

CaBle Heating element

132 ft

144 ft

120 ft

CR-3226

Ring ConneCtoR

8

12

8

in-3488

insulation CoRneR

8 ft

8 ft

8 ft

Bu-3105

sHouldeR BusHing

8

12

8

Bu-3106

Cup BusHing

8

12

8

sl-3063

insulating sleeve

8

12

8

ta-3540

HigH temp eleCtRiCal tape

1 roll

1 roll

1 roll

st-2439

10.32 stud

8

12

8

nu-2215

Hex nut

32

24

32

CALiBRAtiON PROCeDuRes

Every unit is calibrated at the factory. Only a qualified

service technician should calibrate the unit in the field

if necessary.

sHOCk Risk WARNiNG:

Unit must be disconnected

from power source before making adjustments or

calibrating switch.

tOOLs RequiReD:

2mm allen (hex) wrench

CALiBRAtiON