Impulse SCM9B-D100 Series User Manual

Scm9b-d100 series, Din rail mount sensor-to-computer modules, Scm9b

SCM9B

Visit our website www.dataforth.com

107

Isolated Intelligent Signal Conditioning Products

SCM9B

SCM9B-D100 Series

DIN Rail Mount Sensor-to-Computer Modules

Features

Complete Sensor to RS-485 Interface

500Vrms Analog Input Isolation

15 Bit Measurement Resolution

Continuous Self-Calibration; No Adjustments

of Any Kind

Programmable Digital Filter

Requires +5VDC Supply

Transient Suppression on RS-485

Communications Lines

Screw Terminal Plug Connectors Supplied

CE Compliant

▲

Description

The SCM9B-D100 Sensor to Computer Modules are a family of data acquisition

modules that convert analog input signals to digital data and transmit via RS-485

to a controller which may be a computer or other processor-based equipment.

The modules can measure temperature, pressure, voltage, current, digital input

or digital output signals. The modules provide direct connection to a wide variety

of sensors and perform all signal conditioning, scaling, linearization and

conversion to either linearized ASCII data values or Modbus RTU data values.

Features such as address, baud rate, parity, echo, etc., are selectable using

simple commands over the RS-485 port. The selections are stored in nonvolatile

EEPROM which maintains data even after power is removed.

Data is acquired on a per channel basis so you only buy as many channels

as you need. The modules can be mixed and matched to fit your application.

They can be placed remote from the host and from each other. You can string

up to 247 modules on a twisted pair of wires by using RS-485 with repeaters.

All modules are supplied with screw terminal plug connectors. The connectors

allow system expansion, reconfiguration or repair without disturbing field wiring.

Utility software is available from Dataforth to make the D100 easier to learn and

use. The software is provided at no charge on request with a purchase order

and is not copy protected.

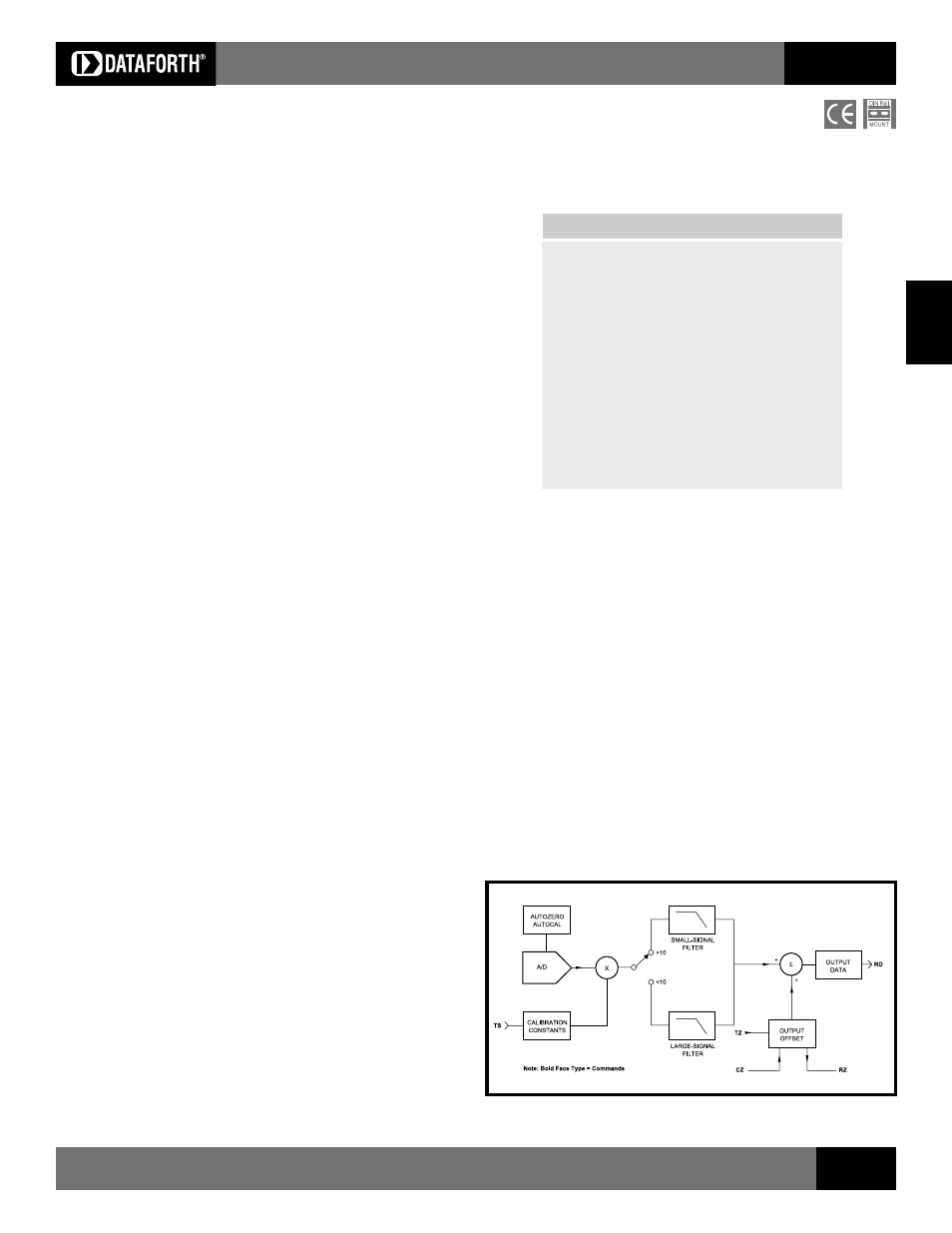

Theory Of Operation

Each Dataforth module is a complete single-channel data acquisition system.

Each unit contains analog signal conditioning circuits optimized for a specific

input type. Sensor signals are converted to digital data with a micro

processor-controlled integrating A/D converter. Offset and gain errors in the

analog circuitry are continuously monitored and corrected using microprocessor

techniques. The D100 converts the digital signal data and stores the resultant

data in a memory buffer. The modules continuously convert data at the rate of

8 conversions per second and store the latest result in the buffer.

Host processors may request data by sending a query to the module. The D100

will instantly respond by communicating the memory buffer data back to the host

processor. Up to 247 modules may be linked to a single RS-485 port. Each

module on a serial line is identified by a unique user-programmable address.

This addressing technique allows modules to be interrogated in any order.

Digital Inputs/Outputs

D170 digital input/output modules contain open-collector transistor switches that

may be controlled by the host processors. These switches may be used to

control solid-state relays which in turn may control heaters, pumps and other

power equipment. The digital inputs may be read by the host processor and

used to sense the state of remote digital signals. They are ideal for sensing the

state of limit or safety switches.

Digital Filter

The D100 analog input modules include two unique programmable single pole

digital filters. The filter is used to smooth analog data in noisy environments.

Separate time constants may be specified for small and large signal changes.

Typically a large time constant is specified for small signal changes to filter out

noise and provide stable output readings. A smaller time constant may be chosen

for large signal changes to provide fast response to such changes.

Command Set

The D100 series uses the Modbus RTU or the Dataforth ASCII protocol for

communication.

The Modbus RTU binary protocol uses a master-slave technique, in which only

the master device can initiate transactions. The slave devices respond by

supplying the requested data to the master or by taking the action requested

in the query. The master can address any slave device. The returned

messages are considered response messages. The supported master codes

are:

Modbus RTU Functions and Descriptions

01

Read Coil Status (Digital Inputs)

04

Read Input Register (Analog Inputs)

05

Force Single Coil (One Digital Input)

06

Preset Single Register (Dataforth/RTU Protocol)

15

Force Multiple Coils (Multiple Digital Output)

The Dataforth ASCII protocol is a command and response protocol using ASCII

characters for easy troubleshooting and interpretation of data values.

Figure 1: SCM9B-D100 Block Diagram