Controlled Products Systems Group LA400 User Manual

Page 11

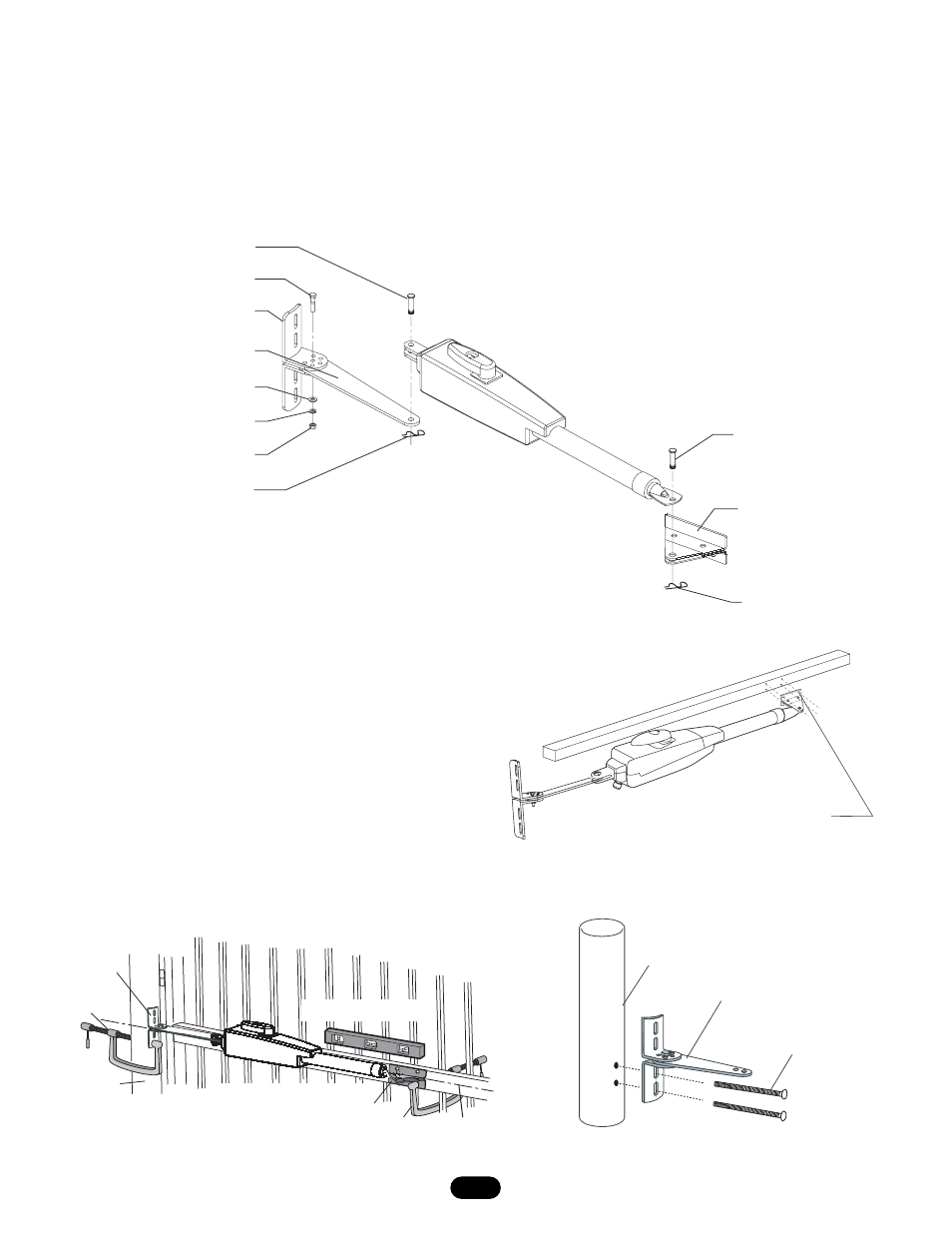

Hex Bolt

Post Bracket

Push-to-Open Bracket

Flat Washer

Lock Washer

Nut

Pin

Pin

Hairpin Clip

Hairpin Clip

Gate Bracket

Figure 4

11

7. Remove pins and detach operator.

8. Mark holes for post bracket assembly and gate bracket. Be sure to

mark holes in the vertical center of post bracket slots.

NOTE: All four mounting holes must be used.

9. Remove brackets from gate post and cross member.

10. Drill 13/32" holes in marked locations for gate posts and 11/32" for

gate bracket.

11. Secure gate posts bracket assembly to gate post using 3/8" bolts,

lock washer, flat washer and nuts. Secure gate bracket to cross

member using 5/16" bolts, lock washer, flat washer and nuts

(Figures 6 & 7).

12. Reattach operator to gate using pins and hairpin clips.

NOTE: After final limit adjustments (page 21) the gate can be closed

slightly further by increasing the distance between center of gate hinge

and the gate bracket by 1" (25 mm). Do not move the post bracket

assembly.

Gate In Open Position

Mark cross member through middle of

gate bracket slots and drill 11/32" holes

LEVEL

Horizontal Cross Member

Figure 6

Post Bracket

Assembly

Mark fence post through

middle of bracket slots

and drill 13/32" holes

3/8"-16 x 6"

Carriage Bolt

Figure 7

Fence Post

Post Bracket

Assembly

Gate In CLOSED Position

Gate Bracket

C Clamp

C Clamp

Operator MUST be level

Vertical Center of

Gate Cross Member

Figure 5

4. Attach operator to gate post bracket by inserting push-to-open

bracket into slot on the motor side of operator. Secure with pin

(Figure 4.)

5. Fasten gate bracket to the actuator side of the operator using pin.

Swing operator to the desired closed position (Figure 4).

6. Position gate to full closed position. Adjust operator until it is level

and position bracket against the cross member. Secure using C

clamp (Figure 5).