1 high voltage connections, Detail a – Controlled Products Systems Group 9210-081 User Manual

Page 26

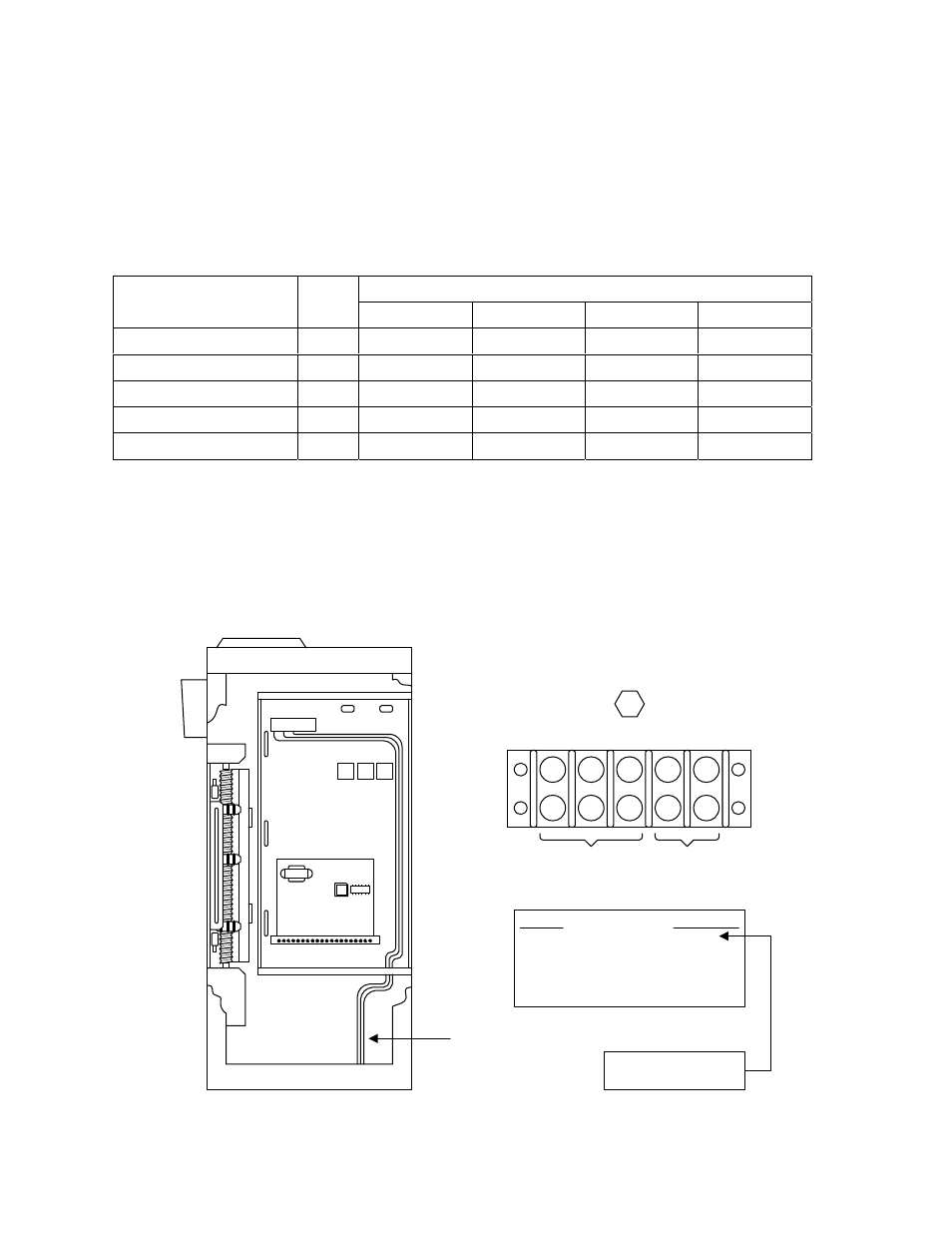

2.1 High Voltage Connections

Use the table below to determine high voltage wire size requirements. The distance shown in the

chart is measured in feet from the operator to the power source. If power wiring is greater than the

maximum distance shown, it is recommended that a service feeder be installed. When large gauge

wire is used, a separate junction box must be installed for the operator connection. The wire table is

based on stranded copper wire. Wire run calculations are based on a maximum 3% voltage drop on

the power line, plus an additional 10% reduction in distance to allow for other losses in the system.

WIRE SIZE / DISTANCE IN FEET

INPUT POWER

AMPS

12 AWG

10 AWG

8 AWG

6 AWG

1 HP: 115 VAC – 1

Ø

15 60

90

150

240

1 HP: 208/230 VAC – 1

Ø

7.5/7.4

200 330 520 840

1 HP: 208/230 VAC – 3

Ø

3.4/3.3

530

840

1340

2100

1 HP: 460 VAC – 3

Ø

1.7

2400 3900 6200 9500

3 HP: 208/230 VAC 3

Ø

12.4

190 310 490 790

Route incoming high voltage power through conduit and into the operator up the right side of the

control box.

Be sure wiring is installed in accordance with local codes. Be sure to color code all wiring.

It is recommended that a surge suppresser be installed on the high voltage power lines to help

protect the operator and circuit board from surges and power fluctuations.

DETAIL A

DETAIL A

L1

L2

L5

L4

L3

GROUND

115 VAC

OUTPUT

HIGH VOLTAGE

INPUT

POWER

TERMINALS

115 VAC SINGLE PHASE

L1 - L2

230 VAC SINGLE PHASE

L1 - L2

208 VAC THREE PHASE

L1 - L2 - L3

230 VAC THREE PHASE

L1 - L2 - L3

460 VAC THREE PHASE

L1 - L2 - L3

INCOMING

POWER WIRES

L1 = HOT (BLACK)

L2 = NEUTRAL (WHITE)

Page

26

9210-065-F-11-07