Operator installation/ surface operator – Controlled Products Systems Group 1603-080 User Manual

Page 7

1603-065-A-10-06

installation guide 7

operator installation/surface operator

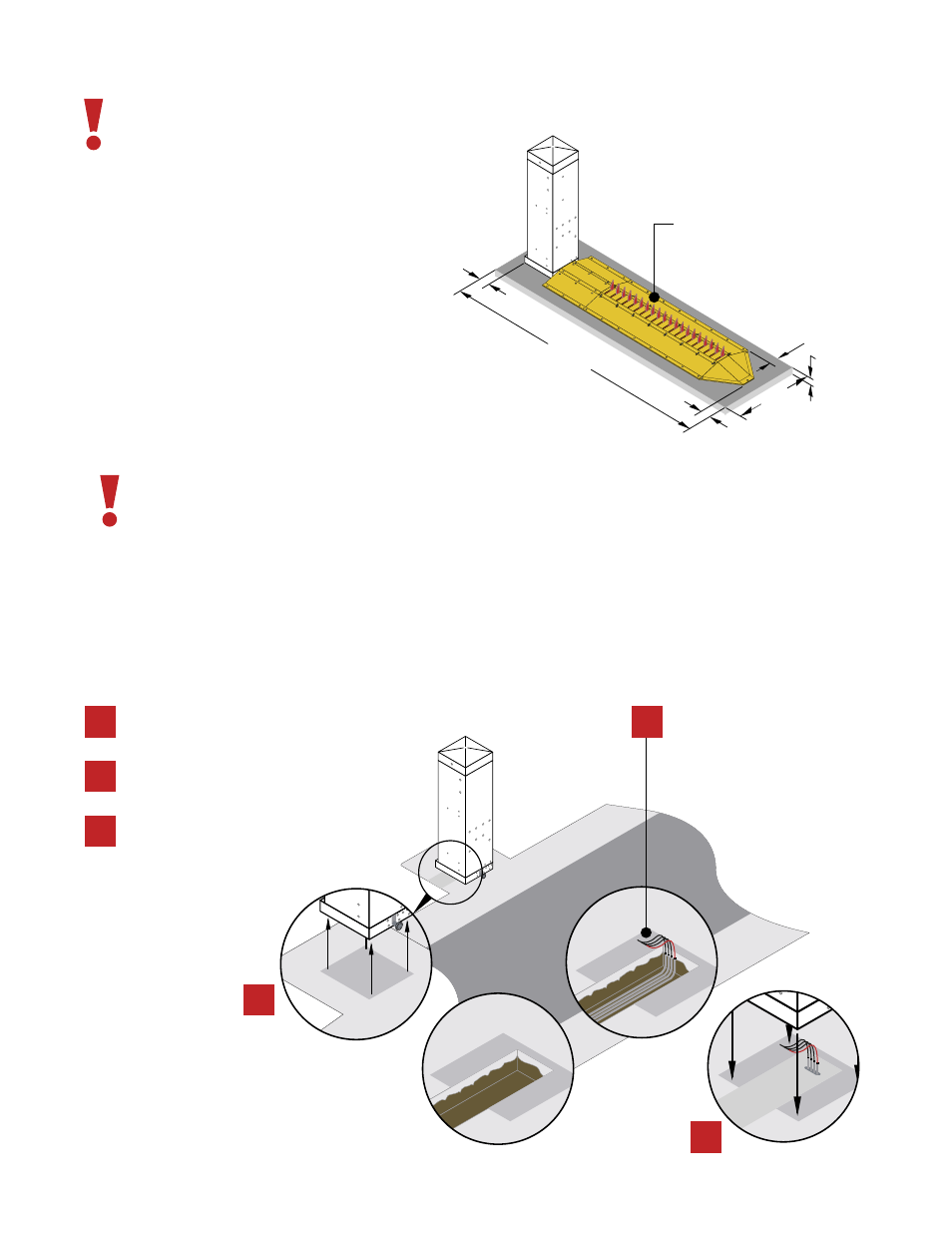

Before installing Operator/Spike system check concrete to be even and leveled, avoiding any Operator/

Spike system unbalance and unevenness.

Conduit requirements may vary depending on your specific needs. Use only sweeps for conduit bends,

do not use 90° connectors this will make wire pulls very difficult and can cause damage to wire insula-

tion. A suggested minimum of 3/4-inch conduit should be used. Be sure that all conduits are installed in

accordance with local codes.

6”

MINIM

UM

D

EPTH

6”

48”

6”

12’ft.

6”

CONCRETE BASE

2

/0%2!4/2

0/3)4)/.

Mix and pour concrete into the trench, al-

low the concrete to cure and place the op-

erator into position.

1

3

From the operator position dig a trench.

NOTE: The trench should enclose the con-

duits.

Run conduits from the operator to their

corrsesponding source .

1

3

•Hi Voltage Conduit

•Low Voltage Conduit

•Loop Lead Conduit

•Sequencing Control or

Primary/Secondary Conduit

2

The operator/spike system must be installed on a concrete

base no less than 6” thick (check your local building codes)

with rebar and/or wire mesh for added strength.

•Concrete base should be even and leveled

avoiding any Operator/Spike system unbalance.

•Mix concrete according to manufacturer.

•Pour and tamp concrete into form.

•Level and surface.

•Allow concrete to cure for 48 hrs.