Controlled Products Systems Group 1044682 User Manual

Page 8

Page 8

November, 2003

402 Operator And

455 D Control Panel Installation Manual

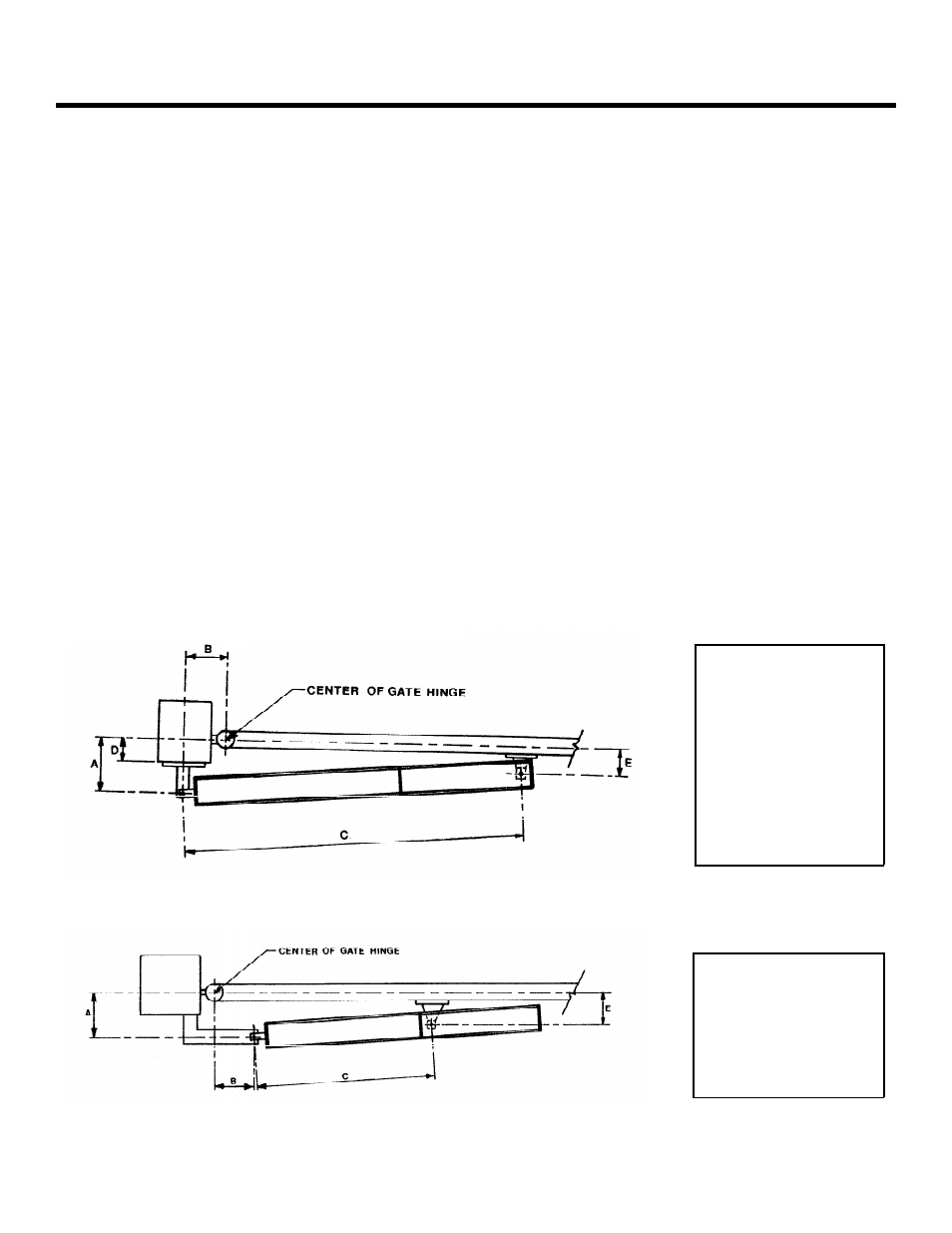

402 Standard

A 4-1/2 in. (114 mm)

B 4-1/2 in. (114 mm)

C 35-1/2 in. (902 mm)

D If greater than 2 in.

(50 mm), construct

a recess liner.

E Must be less than A

Figure 4. An inward swinging gate, top view: important mounting dimensions

Figure 5. An outward swinging gate, top view: important mounting dimensions

402 Standard

A 4-1/2 in. (114 mm)

B 4-1/2 in. (114 mm)

C 26-1/2 in. (673 mm)

E Must be less than A

as instructed below, will ensure proper location

of the front mounting bracket.

Bolt or weld the front mounting bracket to the

marked location on the gate.

WARNING!

Do Not Weld the front mounting

bracket with the operator attached. Doing so

will seriously damage the operator.

A

TTACH

THE

O

PERATOR

TO

THE

G

ATE

Re-attach the operator to the mounting brackets. Once

the operator is mounted and level, remove the vent

screw from the bottom of the valve body. Use a 3mm

hex wrench.

WARNING!

Failure to remove the vent screw may

result in erratic operation of the operator or blown

seals.

Slowly move the gate open and close.

WARNING!

The piston should not bottom out in

either direction. Doing so will seriously damage

the operator.

Be sure that the gate reaches the positive stop

before the piston bottoms out.

After checking the swing of the gate, secure all nuts and

bolts.

Once the operator is secure, install the protective cover

over the piston of the operator, first insert the two

spacers (items labeled 2 in Figure 6) in the front flange

of the operator as shown. The spacers dampen any

vibrations to the operator.

Next, slip the cover over the operator. The slit in the

cover should face the gate, and the cover should be

placed firmly over the rear of the operator cover (item 1

in the figure).

Finally, use the black plastic screws (items 3 and 4) to

fix the cover to the operator and the end cap (item 5).