Npacking, Perator – Controlled Products Systems Group 1044682 User Manual

Page 5

Page 5

November, 2003

402 Operator And

455 D Control Panel Installation Manual

U

NPACKING

THE

O

PERATOR

When you receive your 402 Compact Operator, complete

the following steps.

Inspect the shipping box for physical damage such as

leaking oil or a torn carton. Then inspect the operator

after you remove it from the box. Notify the carrier

immediately if you note any damage because the carrier

must witness the damage before you can file a claim.

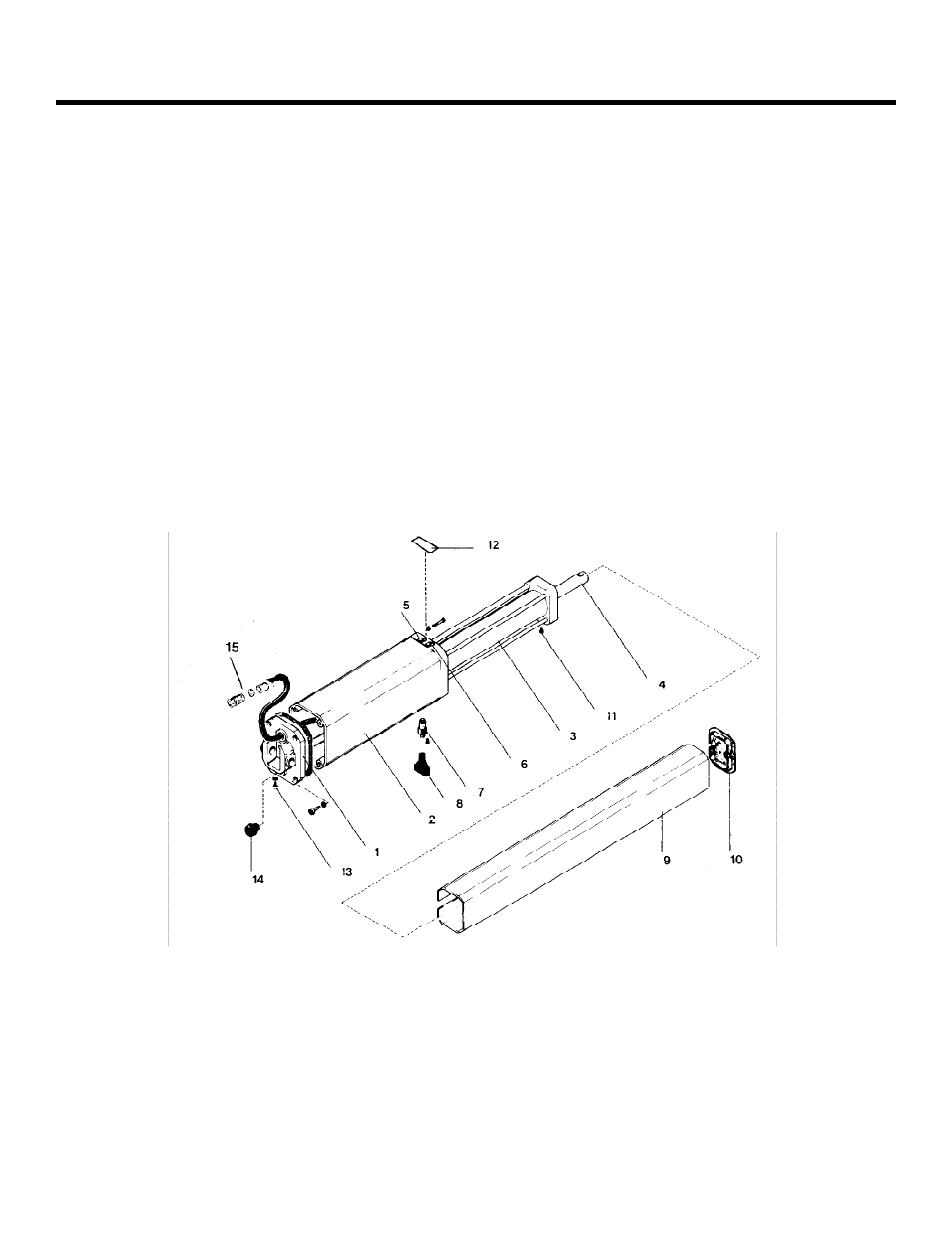

As you unpack the box, insure that all the parts listed

below are included (see Figure 1). If you have ordered a

kit (a pair of operators), you will have twice the quantity

of parts listed below (except where noted), and you will

also have a radio receiver and two transmitters.

1 Control panel box with control panel inside (only 1

per kit)

1 402 Operator unit

1 Protective cover for the operator

1 End cap or guard cover

1 Rear mounting bracket (for post or wall)

1 Rear mounting plate (use is optional)

1 2 in. (50 mm) operator pin with 1 nut for

attachment to rear mounting bracket

1 Mounting fork support

1 2-3/4 in. (70 mm) operator pin with 1 self-locking

nut for attachment to rear flange of operator

1 1-1/8 in. (29 mm) pin for fixing the front coupling

to the operator’s piston rod

2 E clips for either end of the pin fixing the front

coupling to the operator’s piston rod

1 Front

mounting

brackets

1 Nameplate (with 2 screws) for covering pressure

adjustment screws

1 Manual Release key

1

Rear flange

8

Manual Release key

2

Operator casing containing pump and motor

9

Cover

3

Cylinder body

10

Cover end cap

4

Piston rod with hole for attaching to front mounting bracket

11

Cover fixing screw (1 of 2)

5

Green screw for adjusting pressure

12

Nameplate secured with screws

6

Red screw for adjusting pressure

13

Oil vent screw

7

Manual Release Mechanism

14

Oil loading cap

Figure 1. The 402 Compact Operator