Controlled Products Systems Group 1042011 User Manual

Page 8

Page 8

February, 20 09

400 O pe rator And

455 D Control Panel I nst allatio n M anual

A

TTACH

THE

M

OUNTING

H

ARDWARE

Insert the rear fork (hex cut up if you have a nylon rear

fork) into the rear flange of the operator. Secure with

long brass pin and self-locking nut.

Screw the jam nut onto the swivel joint. Slide the

washer on next and screw the swivel joint halfway into

the piston rod. Temporarily attach the front mounting

bracket to the swivel joint with the nut and bolt

provided.

A

TTACH

THE

F

RONT

M

OUNTING

B

RACKET

TO

THE

O

PERATOR

Release the operator as shown in Fig. 3. Put the

operator into position and attach the rear fork to the

rear mounting bracket using the short brass pin,

washer, and nut.

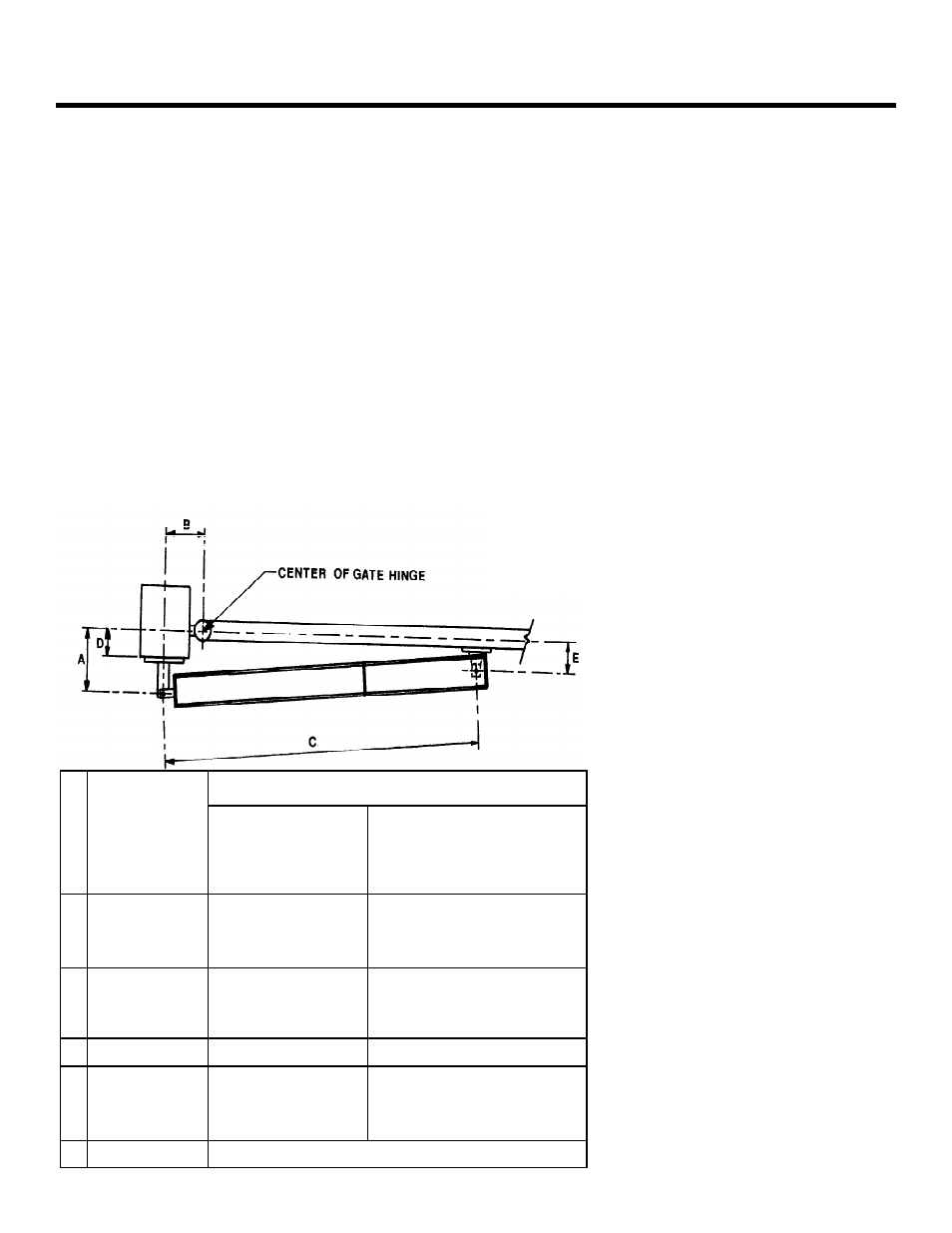

* For A, B, and D, if you choose one

of these values with one asterisk,

then you must choose the other

values with one asterisk.

** For A, B, and D, if you choose

one of these values with two

asterisks, then you must choose the

other values with two asterisks.

For inward swing, pull the piston out completely and

push back approximately ¼” (6mm). For outward swing,

push the piston in completely and pull back out

approximately ¼” (6mm).

Note:

Be sure that the operator is level and that

the gate is against the close positive stop.

Hold the front mounting bracket flush against the gate.

Mark the location of the front mounting bracket.

Remove the operator from the gate. Remove the front

mounting bracket from the swivel joint.

Note:

Clamping the front mounting bracket at the

marked location before checking the swing, as

instructed below, will ensure proper location of the

front mounting bracket.

Bolt or weld the front mounting bracket to the marked

location on the gate.

WARNING!

Do not weld the front mounting

bracket with the operator attached. Doing so will

seriously damage the operator

.

Desired Swing

Dimensions, in. (cm)

400 Standard

High speed and

Slow speed models

400 Long

A

90-deg swing

115-deg swing

125-deg swing

5 (13)

4 (10)

N/A

7 7/8 (20)* or 11 1/2 (29)**

5 3/4 (14.6)

5 1/8 (13)

B

90-deg swing

115-deg swing

125-deg swing

5 (13)

4 3/4 (12)

N/A

7 1/2 (19)* or 3 (7.5)**

7 (17.8)

6 5/8 (17)

C

All Swings

38 3/16 (97)

47 5/8 (121)

D

90-deg swing

115-deg swing

125-deg swing

Max 3 (8)

Max 2 (5)

N/A

Max 5.5 (14)* or 9.5 (24)**

Max 3 1/2 (8.9)

Max 2 3/4 (7)

E

All Swings

Must be less than A

Figure 4. Important mounting

dimensions for inward swing 400

operators, top view