0 temperature compensation, 0 single transducer operation, 0 troubleshooting – Cleveland Motion Controls Classic Slim Cell Transducer REV AA User Manual

Page 7

INSTRUCTION NUMBER: AO-70165

7of 9

4.0

TEMPERATURE

COMPENSATION

The transducers are supplied with a temperature

compensation network (except size 1 that don’t

require it) which is in series with the output signal

lead. The compensation circuit is designed to be

used with a tension amplifier, which has an input

impedance of 10K Ohms when a pair of transducers

connected as a full bridge is used. If only one

transducer is used, the tension amplifier impedance

should be 5K Ohms. If other than the input

impedances given above are used, drift will occur in

the tension amplifier output when the transducer

temperature changes.

5.0

SINGLE TRANSDUCER

OPERATION

For those applications where only one transducer is

required, a dummy circuit may or may not be

required depending upon the input circuit of the

tension amplifier. Consult the factory for this

information. The dummy circuit consisting of two

resistors is substituted in place of the second

transducer. The resistors should have a resistance

value between 100 and 150 Ohms and should be

matched to within 1%. Dummy circuits are available

from the factory for connecting to tension indicators

or controllers.

6.0

TROUBLESHOOTING

6.1

EXCESSIVE OUTPUT SIGNAL

WITH NO LOAD

There may be a high degree of misalignment of the

transducers causing a severe pre-load.

Or

The sensing guide roll assembly may be excessively

heavy. The sensing guide roll should not weigh more

than _ the maximum working force of the

transducers in most cases.

Or

The transducer may have too small a maximum

working force for the application. Replace with a

higher maximum working force transducer or

decrease the web wrap angle.

6.2

LOW OUTPUT SIGNAL

The transducer may have too large a maximum

working force for the application. Replace with a

lower maximum working force transducer or increase

web wrap angle.

6.3

WRONG POLARITY OF OUTPUT

SIGNAL

Transducers may have been incorrectly oriented. See

Section 2.4 for proper load direction. Alternately,

change the transducer excitation voltage by

interchanging the B and C connections.

6.4

OUTPUT SIGNAL NOT LINEAR, ZERO

SHIFTS DURING OPERATION

Check transducer and tension roll mounting. All

mounting bolts must be tight. Check that there is no

dirt or foreign matter interfering with the transducer

mounting. Check that mounting surface is flat and

rigid.

6.5

NO OUTPUT SIGNAL

Check to see that all connections have been made

completely. Check for places where the connecting

cables might be crimped or cut.

6.6

VERY HIGH OUTPUT WITH NO LOAD

Check cables and connectors for good connections and

check continuity of cables with an ohmmeter. Check

for proper wiring to transducers. Check transducer

gage resistance as given in the following chart at room

temperature with no load applied.

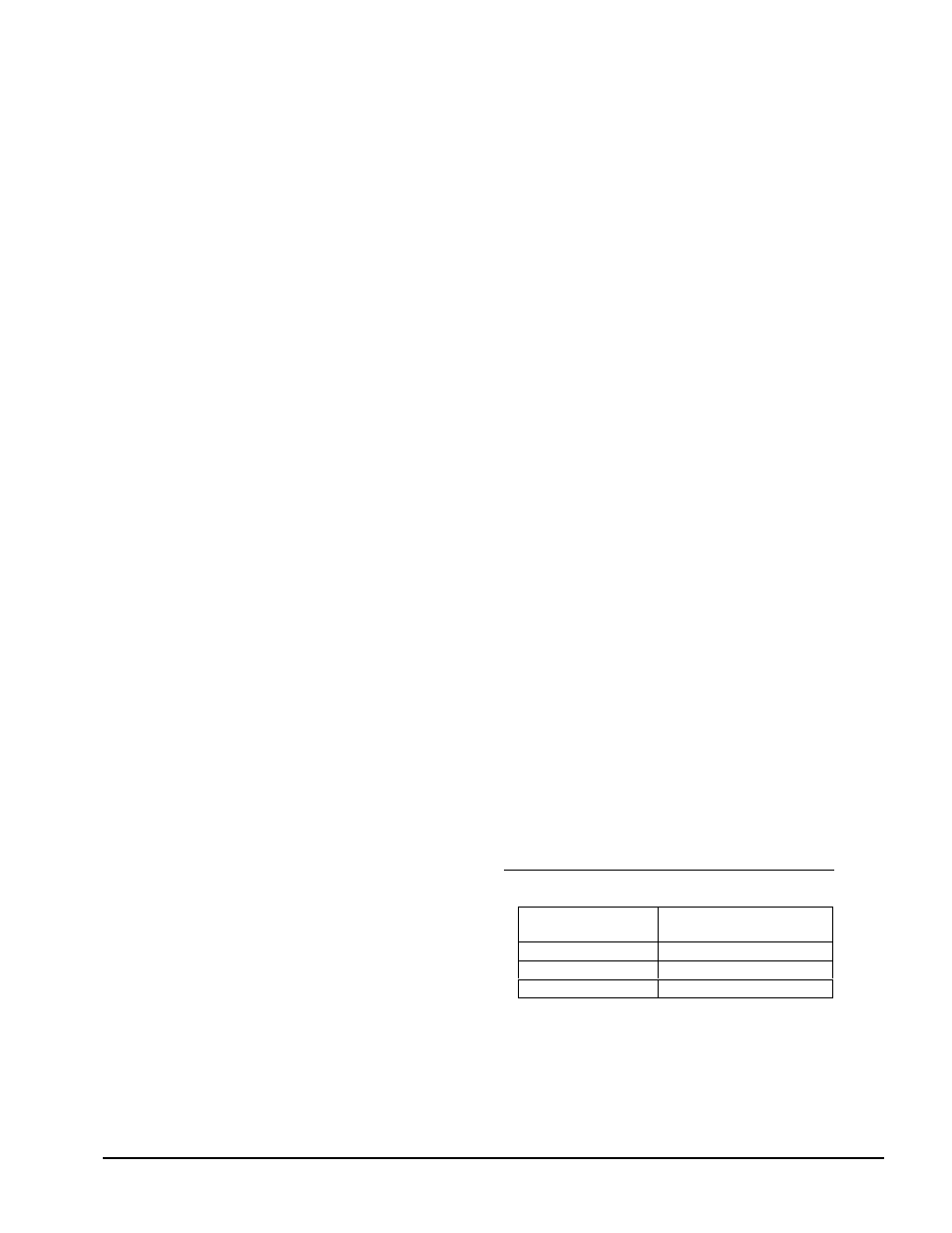

TRANSDUCER GAGE RESISTANCE CHECK

Resistance

(ohms)

SLIM CELL 1 or 2

Pin C to B

420±20

Pin A to B

900-1100

Pin A to C

900-1100