0 installation, Figure 4 – Cleveland Motion Controls Classic Slim Cell Transducer REV AA User Manual

Page 4

INSTRUCTION NUMBER: AO-70165

4of 9

2.0 INSTALLATION

2.1 SELECTION OF TRANSDUCER

MOUNTING LOCATION

When selecting a transducer mounting location,

keep in mind that the tension-sensing roll must

NOT be mounted where the web wrap angle can

vary. Any change in the wrap angle will be sensed

by the transducers as a change in tension, and

indicated as such on the tension indicator.

Figure 3

In some cases, it may be impossible to find a

location for the transducers where the wrap angle

does not vary. The change in indicated tension that

will result can be calculated and, if small, may not

be significant.

2.2

MOUNTING SURFACE PREPARATION

The mounting surfaces for the transducers should

be flat and parallel. Prepare the machine frames or

mounting surfaces by removing any loose paint,

rust, scale, etc.

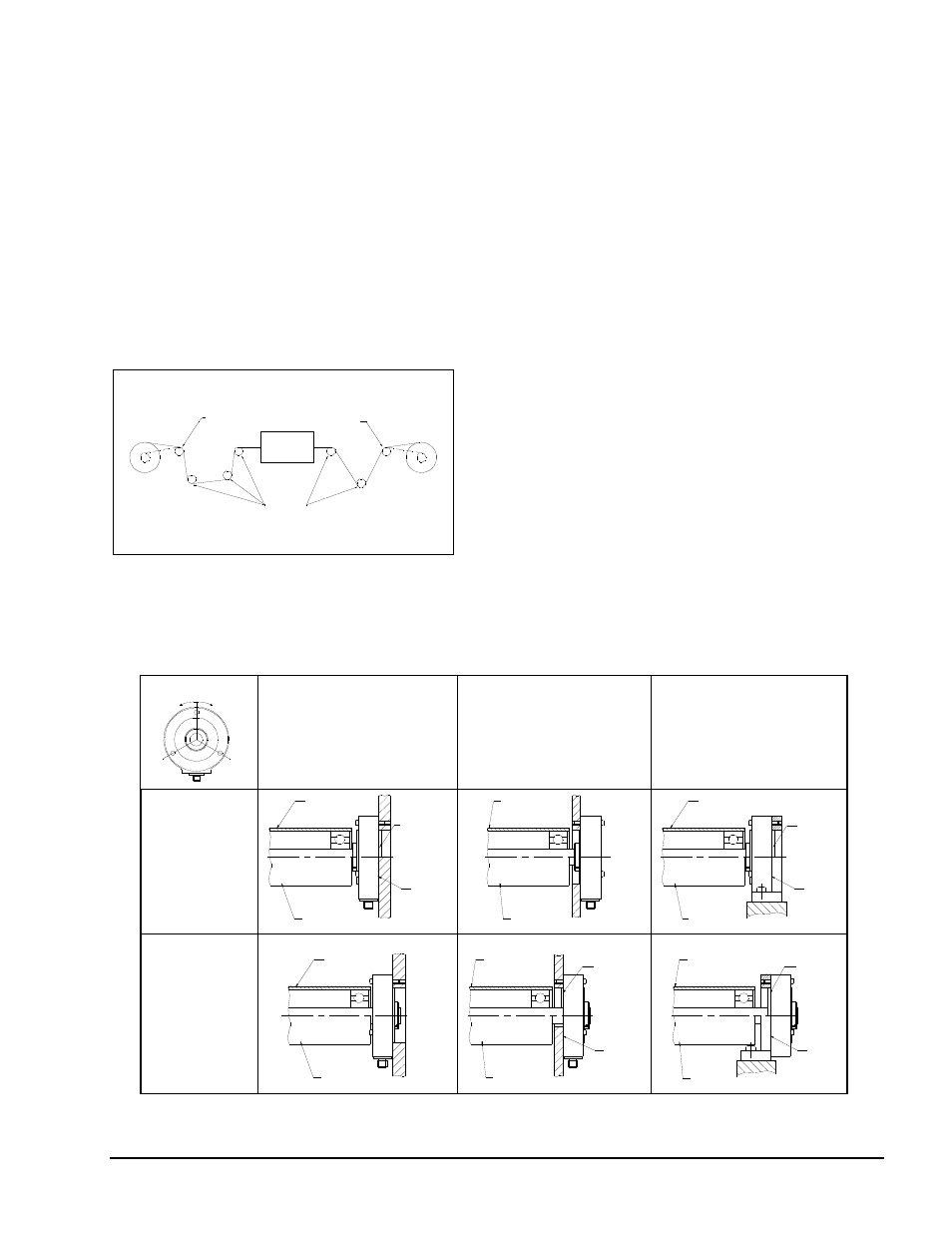

2.3 MOUNTING STYLE

The SLIM CELL Transducer is very versatile and

can be mounted in several mounting styles. If you

have not decided which style to use, evaluate which

is the most convenient, based on the machine

frame, ease of assembly and protection.

See Figure 4.

62 DEG OF ANGULAR ALIGMENT

WITH BOLT IN POSITION

WITH DEAD SHAFT

BP

FLUSH

WITH LIVE SHAFT

BF

HF

WITH LIVE SHAFT

WITH DEAD SHAFT

WITH DEAD SHAFT

WITH LIVE SHAFT

BF

WITH DEAD SHAFT

FLUSH

WITH LIVE SHAFT

HP

HF

WITH DEAD SHAFT

FL

USH

BP

BF

WITH DEAD SHAFT

FL

USH

H

P

H

F

WITH MOUNTING

BRACKET

OUTSIDE

FRAME

INSIDE

FRAME

BLANK BACK

PLATE

BACK PLATE

WITH HOLE

WITH ALIGNMENT

PILOT

WITH LIVE SHAFT

WITH AL

IGN

MENT

PILOT

WITH ALIGNMENT

PILOT

WITH LIVE SHAFT

WITH A

LI

GNMEN

T

PILOT

Figure 4