Mounting configurations, N 2.2.3 on – Cleveland Motion Controls ULTRA SERIES CARTRIDGE TRANSDUCER REV AA User Manual

Page 10

U

LTRA

S

ERIES

S

TATIONARY

S

HAFT

T

RANSDUCER

MAN-70251

R

EV

.

AA

P

AGE

10

OF

18

2.2.3 M

OUNTING

C

ONFIGURATIONS

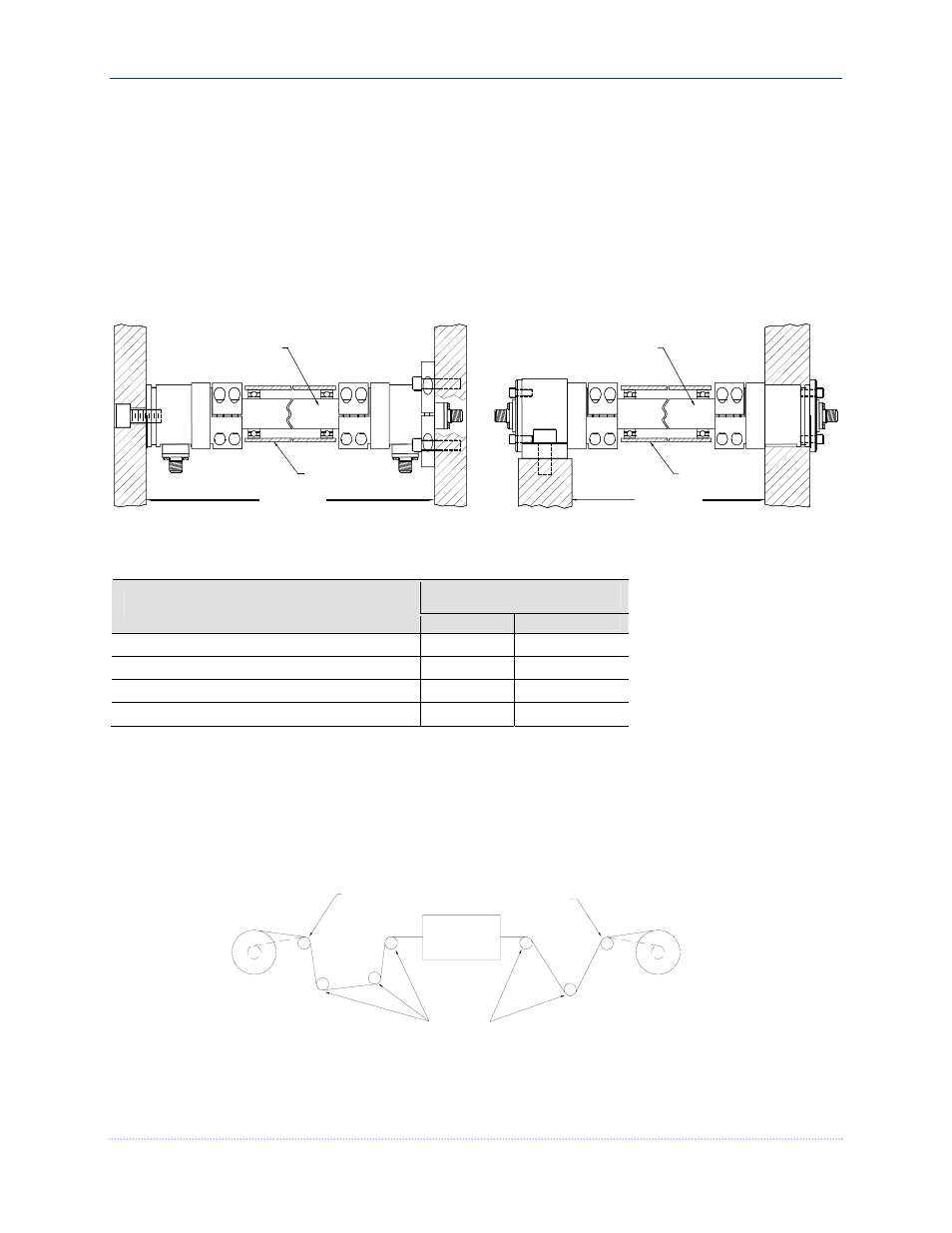

Ultra Series Cartridge Transducers can be mounted on either the inside or outside of the machine depending on the

model type purchased (refer to Figure 1 and Table D). When choosing a mounting configuration, evaluate your

options by taking the following points into consideration:

• Model type

• Safety

• Machine Frame orientation

• Ease of Assembly

MACHINE FRAME

TYPE "S"

MOUNTING

TYPE "FL"

MOUNTING

SENSING ROLL

SENSING ROLL

TYPE "PB"

MOUNTING

TYPE "BR"

MOUNTING

STATIONARY/DEAD SHAFT

STATIONARY/DEAD SHAFT

MACHINE FRAME

Figure 2 – Types of Mounting Configurations

Table D – Mounting Type and Connector Compatibility

The Connector can be located

at:

When using this type of Mounting

Configuration:

End

Side

Flange (FL)

X X

Stud (S)

X

Pillow Block (PB)

X

Bearing (BR)

X

The tension-sensing roll must not be mounted where the web wrap angle can vary, or the transducer will not

interpret the tension properly. If a variance in the wrap angle occurs, it is sensed by the transducer as a tension

change and the change is indicated on the tension indicator. In cases where it is impossible to mount the transducer

where the wrap angle does not vary, the change in indicated tension that results should be calculated and if small,

can be disregarded.

WRAP VARIES

WRAP VARIES

PROCESS

OK FOR TENSION SENSING

Figure 3 - Example of Varying Wrap Angles