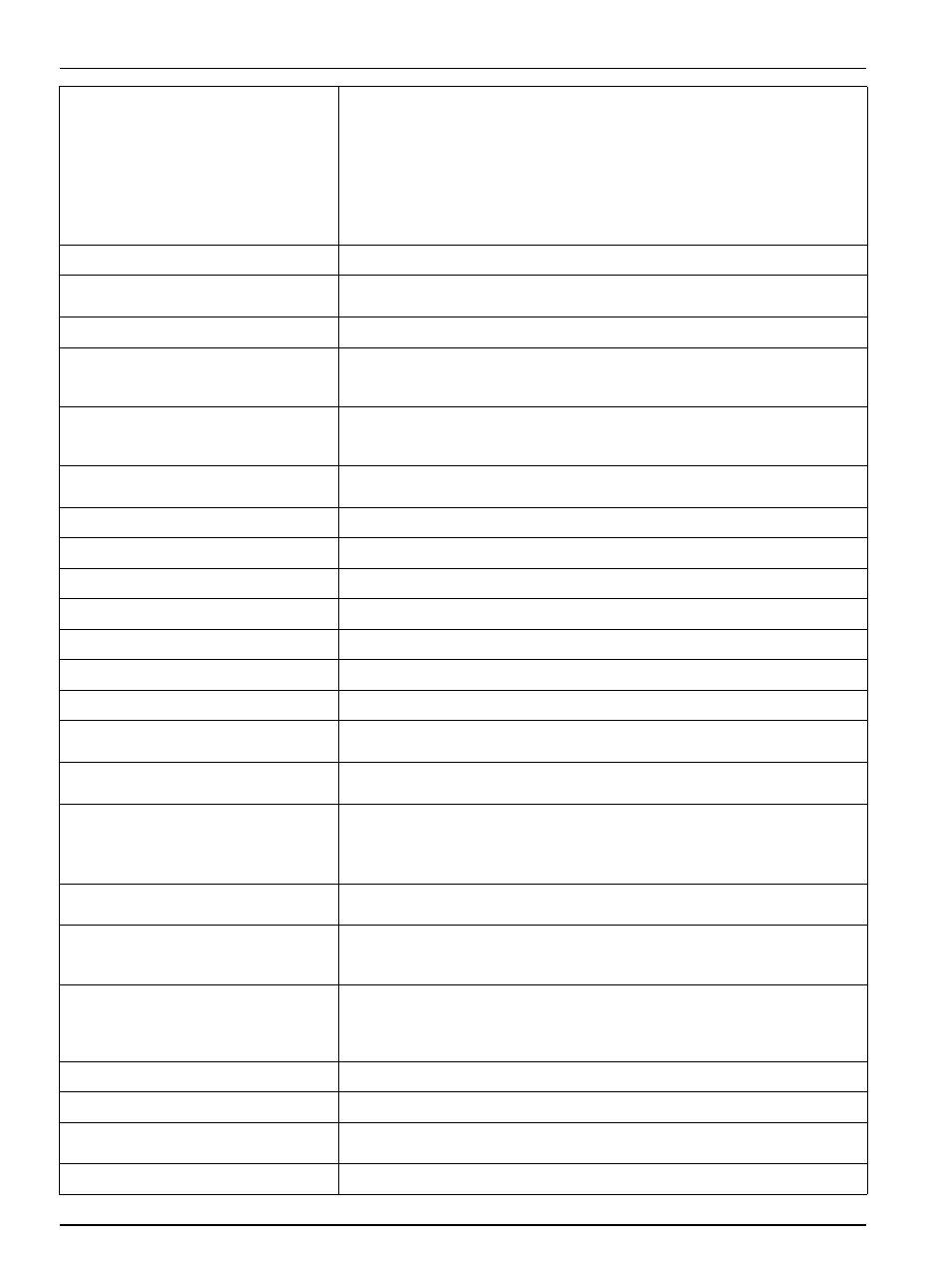

Specifications – Hach-Lange Sigma SD900 Portable User Manual

Page 8

6

Specifications

Pump tubing life

20,000 sample cycles under the following conditions:

• 1 L sample volume

• 1 rinse

• 6 minute pacing interval

• 16 ft of

3

/

8

in. intake tube

• 15 ft of vertical lift

• 70 °F sample temperature

Tubing replacement time

< 1 minute using pre-cut pump tube

Maximum vertical lift to draw sample

Minimum of 28 ft, using 29 ft of

3

/

8

-in. vinyl intake tube at sea level at 20–25 °C

(68–77 °F)

Pump flow rate

1.25 gpm (4.8 L/min) at 3 ft (1 m) vertical lift using

3

/

8

-in. intake tube

Typical sample volume repeatability

± 5% of 200 mL sample volume using uncalibrated liquid detect with 15 feet

vertical lift,16 feet of

3

/

8

-in. vinyl intake tube configured for a single bottle using full

bottle shut-off at room temperature and 5000 ft elevation

Typical sample volume accuracy

± 10% of 200 mL sample volume using uncalibrated liquid detect with 15 feet

vertical lift,16 feet of

3

/

8

-in. vinyl intake tube configured for a single bottle using full

bottle shut-off at room temperature and 5000 ft elevation

Typical transfer velocity

2.9 ft/s (0.9 m/s) with 15 ft (4.6 m) vertical lift, 16 ft of

3

/

8

-in. vinyl intake tubing,

70 °F (21 °C) and 5000 ft elevation

Liquid sensor

Ultrasonic

Liquid sensor body

Ultem

®

NSF ANSI standard 51 approved, USP Class VI compliant

Internal battery

Lithium

Internal clock

Indicates real time and date

Storage temperature

–30 to 60 °C (–22 to 140 °F)

Operating temperature

0 to 50 °C (32 to 122 °F)

Storage/operating humidity

100% condensing

Graphics display

Graphic dot matrix, 128 x 64 pixel with LED backlight. Self prompting,

menu-driven program.

Status display

Indicates the number of samples collected, the number of missed samples,

inhibit mode, bottle position, time or counts to next sample and battery voltage

Automatic shutdown

Multiple bottle mode: after complete revolution of distributor arm (unless

Continuous Mode is selected).

Composite mode: after preset number of samples have been delivered to

composite container, from 1 to 999 samples, or upon full container.

User interface

Embossed keypad with one power key, four function keys, and eight navigation

keys; LED indicator

Sample history

Stores up to 255 entries for sample time stamp, bottle number and sample status

(success, bottle full, rinse error, user abort, distributor error, pump fault, purge fail,

sample timeout, power fail and low main battery)

Event log

Records Power On, Power Fail, Firmware Updated, Pump Fault, Distributor Arm

Error, Low Memory Battery, Low Main Battery, User On, User Off, Program

Started, Program Resumed, Program Halted, Program Completed, Grab Sample,

Tube Change Required

Connections

Power, auxiliary, serial communications and distributor

Fittings

Barbed fittings for

3

/

8

-in. I.D. flexible tubing

Wetted materials

Typical materials in contact with sample: stainless steel, PE, Teflon, Ultem, Silicon

or approved materials that can be tested for leaching properties

Weight

4.2 kg (9 lb, 5 oz)